TECHNICAL INSTRUCTIONS

4853989

10/ 2003

Our policy is one of continuous improvement and we reserve the right to alter specifications of our products at any time.

- 7 -

PREPARATION

Before installing the pump, clean the suction and discharge flanges thoroughly and remove the protective

coating from pump shafts, where applicable.

If the pump has been in storage and prepared in the manner as above, the bearing grease should be

removed, the bearings cleaned (using an approved cleaning fluid) and then re-lubricated following the

procedure detailed in Section 4. It is strongly recommended that this work is carried out by PEERLESS

PUMP COMPANY Service. This is a chargeable service; however pump warranty will be protected.

2.4

LOCATION

The pump should be installed as near to the liquid source as possible, with the shortest and most direct

suction pipe practical.

Allow sufficient accessibility for inspection and maintenance, and ample headroom should be allowed for

the use of an overhead crane or hoist sufficiently strong to lift the unit.

Where pumps are electric motor driven, power source electrical characteristics should be appropriate for

those shown on motor data plate.

2.5

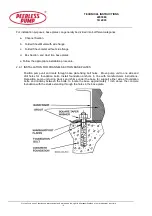

FOUNDATION

The foundation should be sufficiently substantial to absorb vibrations and rigid enough to avoid any twisting

or misalignment. As a rough guide it should be 12 inches wider on all sides with the weight at least 1-1.5

times as heavy as the pump unit. Depth should be sufficient to achieve the necessary weight and deep

enough to accommodate holes for foundation bolts. A suitable concrete mixture by volume is 1:2:3 (Cement

: Sand : Aggregate). The foundation should be reinforced with layers of 6 inch square No.8 gauge steel wire

fabric, or equivalent, horizontally placed 6 inch apart.

Loose bolt type anchors should be checked for tightness periodically, as there is a tendency to loosen with

vibration. Chemical type anchors are a suitable alternative.

2.6

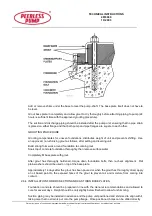

INSTALLATION OF BASE PLATES

Foundation concrete should be poured without interruption to within .5 to 1.5 inch of the finished height. The

top surface should be well scored and grooved, before the concrete sets, to provide a bonding surface for

the grout. The foundation should be allowed to cure for several days before the base plate is shimmed and

grouted.

Chemical Anchor type foundation bolts are recommended as these are less inclined to loosen in service,

and generally simplify installation. Manufacturer's instructions for installation and final torque figures should

be rigorously followed.

Allow enough bolt length for grout, shims, lower base plate flange, nuts and

washers.

Anchor bolt diameter should be the largest capable of being inserted through the base plate

foundation holes.

Summary of Contents for HYF

Page 2: ......