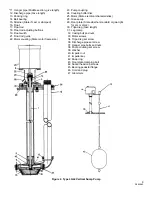

Vertical sump pumps

Type LG and LGL2

Instructions

•

Installation

•

Operation

•

Maintenance

Read this entire book

before attempting to install, operate or repair this

pump. Properly installed, your Peerless sump pump

will give you satisfactory, dependable service. We

urge that you read carefully these step-by-step

instructions, to simplify any problems of installation,

operation or repair.

Failure to read and comply with installation and

operating instructions will void the responsibility of

New equipment manufactured by Seller is warranted

to be free from defects in material and workmanship

under normal use and service for a period of one year

from date of shipment; Seller’s obligation under

this warranty being limited to repairing

or

replacing at its option any part found to its

satisfaction to be so defective provided that such

part is, upon request, returned to Seller’s factory

from which it was shipped, transportation prepaid.

This warranty does not cover parts damaged by

decomposition from chemical action or wear caused

by abrasive materials, not does it cover damage

resulting from misuse, accident, neglect, or from

improper operation, maintenance, installation, modi-

fication or adjustment. This warranty does not

cover parts repaired outside the Seller’s factory without

prior written approval. Seller makes no warranty as to

starting equipment, electrical apparatus or other

material not of its manufacture, since the same are

usually covered by warranties of the respective

manufacturers thereof.

the manufacturer and may also result in bodily

injury as well as property damage.

This book is intended to be a permanent part of your

pump installation and should be preserved in a

convenient location for ready reference. If these

instructions should become soiled, obtain a new

copy from Peerless Pump. Include model, and/or serial

umber with your request.

WARRANTY

In the event, notwithstanding the terms of this

agreement, it is determined by a court of competent

jurisdiction that an express warranty has been given

by Seller to Purchaser with respect to the head,

capacity or other like performance characteristics of

said equipment, Seller’s liability for breach of the

same shall be limited to accepting return of such

equipment F.O.B. plant of manufacture, refunding

any amount paid thereon by Purchaser (less

depreciation at the rate of 15% per year if Purchaser

has used the equipment for more than thirty (30) days)

and canceling any balance still owing on the

equipment.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED,

AND SELLER SPECIFICALLY DISCLAIMS ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

2899982

REV 11/76