INTRODUCTION

UPON RECEIPT OF PUMP EQUIPMENT:

Check

carefully to see that all of the equipment has been

received. Report immediately any shortages or

damages to the transportation company handling the

shipment, noting the extent of the damage or

shortage on the freight bill and bill of lading.

Do not leave the unit exposed to weather or

construction hazards. The pump may become

mechanically damaged. This pump is a well designed

LOCATION:

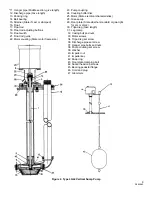

The pump basin should be so located

that the motor and pedestal (8, figure 2) are above

the floor level and are situated in a clean, drained,

well ventilated place, readily accessible for installa-

tion, inspection, and care of equipment. Overhead

room must allow for removal of the unit from the

basin for cleaning or repairs.

BASIN:

The basin should be constructed as tightly

as possible of a material such as steel plate, cast

iron, sewer tile, sewer crock, or concrete, depending

upon local requirements and personal preference.

Never discharge hot water or boiler blow-off into the

pump basin without first chilling. There must be at

least a 4-inch clearance below the strainer, the total

basin depth depending upon drainage requirements.

Pump parts, and the tools and

4. Replace the float rod and buttons to their original

positions.

lifting equipment used in install-

ation are heavy and may easily cause personal

injury if dropped or carelessly handled. The

normal precautions and safety rules associated with

the installation or repair of machinery, in regard to

manual lifting, use of power equipment, and

handling of tools, must be observed in the

installation of this pump.

FLOOR PLATE:

The split floor plate on the LG units

is adjustable and clamps firmly onto the hanger pipe

and discharge pipe at any level desired. The LGL2

bolts firmly to the motor pedestal and should be

firmly fixed over the basin using expansion bolts in

concrete or cap screws into an angle iron curbing or

basin cover. Three bolt-holes are provided in the floor

plate to insure a firm setting. Where a gas-tight unit

is provided, use a gasket ring under the floor plate

and vent the basin to the atmosphere, using the vent

opening provided in the floor plate.

Mounting the Floor Plate:

The floor plate is fixed in

location on LGA and LGL2 models. On the LGB units

the floor plate is furnished in two pieces marked

“left” and “right” which are held together by a bolt and

nut.

and carefully manufactured unit. It should be given

the same attention accorded to any precision

machine.

The satisfactory operation of a pump depends to a

large extent upon proper installation. These instruc-

tions cannot answer every question that may arise as

each installation will be different. The installer and

the operator of this equipment must use good

judgment to adapt these procedures to the

installation.

INSTALLATION

1. Before mounting the plate on the unit, loosen the

float rod buttons (18, figure 2) and remove the

float-rod assembly (16 and 17) from the unit by

lowering it out of the switch arm and float rod guide

(21).

2. Clamp the floor plate loosely to the hanger pipe

(10) and discharge pipe (12) at about the center of the

top hanger pipe, using the bolt and nut provided.

Make sure the half marked “right” is placed on the

float side of the unit.

3. Slip the plate up into place (check length desired),

line up the halves, and draw the nut up tight

clamping the plate firmly to the hanger pipe and

discharge pipe.

WARNING

FLOAT SWITCH ADJUSTMENT:

The unit may be

adjusted by raising or lowering the float rod

adjusting buttons (18) to start and stop the pump at

the desired levels of water in the basin. The

adjusting buttons should usually be set so that the

float drops to several inches above the pump casing

(6) and in rising closes the float switch 10 to 18

inches above this level; naturally this is varied

according to conditions.

MOUNTING TRIPOD LEGS:

On LGA units the legs

are mounted separately. Insert the leg pipe (30) into

the hole provided on the bottom of the bearing

pedestal (45). Set the leg flush with top of the boss,

then insert and tighten the set screw (34). Slip a leg

clamp (31) onto the leg and up into position. Using

the outer nut (32) present on the adjacent casing bolt

fasten the clamp to the casing. The procedure is the

same for all three legs. Adjust the leg lengths to

make the pump stand vertically even though it may

be set on a sloping floor.

4

2899982