Before installing the pump, the

drainage system served should be

flushed out and the pump basin thoroughly cleaned

of any foreign matter [such as chunks of wood,

stones, wire, sludge, and rags] that is liable to affect

pump operation, damage the unit, or clog the

strainer. Also check the float rod guide [21] to see

that the rod alignment is correct so that the float rod

mechanism is able to move freely.

Do not work under a suspended

object unless there is a positive

support under it to stop its fall in event of sling or

hoist failure. Disregard of this warning could result

in grave personal injury.

Never attempt to lift, lower or raise

the sump pump with the motor power

cord. Always use a sling or wire rope, secured only to

pedestal, and a hoist to lower or raise pump.

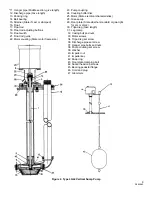

SETTING THE UNIT:

If the pump is of the floor plate

type, check pump length (from bottom of floor plate

to bottom of strainer) and compare with basin depth;

be sure of minimum 4-inches clearance. Se the unit

carefully into the basin, taking precautions not to

crush or damage the float. Face the discharge pipe

as desired and bolt the unit firmly into place.

PIPING:

The discharge pipe should include a union,

a horizontal swing check valve, and a gate valve all

near the pump, and should be run to a point above

the sewer level so as to drop into the sewer from

above. This facilitates easy removal of the unit for

repairs or cleaning and helps prevent backing-up of

sewer water in the event of high water conditions.

The size of the discharge pipe should not be smaller

than that of the discharge connection on the pump,

and where runs are long should be at least a size or

two larger.

It is important that the pipe connections to the unit

be made so that there is no pipe strain upon the

unit. Where quiet operation is important a small

section of rubber hose can be included in the

discharge line to prevent transmission of vibration

noise.

CONTROLS:

With standard single phase LG pumps,

no controls or wiring are necessary. These units are

Due to automatic switch opera-

tion

of

sump

pumps,

tie

the

main disconnect switch open or remove fuses from

main lines before attempting lubrication,

self contained, have the switch already mounted and

wired, and are provided with cords and standard

plugs for connection to any socket. But the line used

must have the proper electrical characteristics and be

provided with the proper fuse. In the event that this

line is used for other appliances or for lighting, a

special fuse serving only the sump pump should be

incorporated in the line.

CAUTON

Before attempting hook-up,

handling, or repair of electrical

wiring, be certain that the electrical supply source is

shut off. An electrical shock from contact with live

wires or cords can be fatal.

WARNING

WARNING

The single phase LGL2 pumps must be wired to the

service provided. Always provide a fused, manual,

motor disconnect switch in the main line. If a fused

motor disconnect switch is not provided in the motor

circuit, there will be danger to life when necessary to

work on the circuit, or there may be danger of fire if

the motor is overloaded and overheats.

CAUTION

All three phase motors must be wired to the service

through a magnetic starter. The float switch provided

must only be used to pilot the magnetic starter in

three phase installations.

Be sure the voltage and frequency

Indicated on motor nameplate are the

same as service provided. If the motor has been

wired at the factory, note the voltage caution card. If

available service is other than that indicated, consult

motor manufacturer’s instructions for proper wiring

changes.

CAUTION

WIRING:

Connect the electric service to the controls

and make inter-control electrical connections when

necessary according to wiring instructions accom-

panying the switches, using conduit and wire sizes

as required by local and national electrical codes. It

is best to include a short section of flexible conduit

adjacent to the motor for convenience in pump or

motor repair.

FUSES:

It is recommended that Fusetron (duel

element) fuses be used if not other thermal or motor

protecting device is used. The Fusetron provides for

motor protection against burn-out. Care must be

taken in selecting the proper size Fusetron. When a

fuse blows it indicated that something is wrong

either in the motor, pump, switch, fuse rating or

service. Do not replace a fuse until you find and

remove the cause of the blow-out.

LUBRICATION

WARNING

mechanical and electrical examinations, or repairs.

attach a card “DO NOT CLOSE SWITCH – PUMP

REPAIR IN PROGRESS.” Disregard of this warning

may result in serious personal injury or death.

5

2899982