Motor: See that the motor comes up to speed

quickly and maintains constant rotation rate.

ROUTINE CARE:

General cleaning: Keep the interior and exterior of motor

and

automatic

apparatus

free

from

moisture,

oil and dirt.

Basin cleaning: Occasionally run the pump until the

basin is drained of water, open the electric circuit,

disconnect the discharge pipe at the union, (also, if

pump is of floor plate type, remove the anchor bolts)

and pull the pump out of the basin. Clean out sludge

or foreign matter accumulated in the basin and on

the strainer before returning the pump to service.

Lubricating: At regular intervals lubricate motor and

pump as directed under Lubrication.

Before attempting examination

or repairs to pump open the

disconnect switch to electric motor. This prevents

accidental running of pump motor. Starting motor

during examination or repair activities could damage

pump and may cause personal injury.

IF PUMP FAILS TO OPERATE:

1. Check fuses or thermal units, see if blown,

thrown, or loose. Before replacing or resetting be

sure the cause for the open circuit is determined and

corrected.

2. See if shaft rotates freely, try turning by hand.

3. See that switch contacts are not corroded,

shorted, or electrical service broken anywhere in the

circuit.

4. Check power supply and compare with motor

nameplate data.

5. Have motor windings ground tested for short.

IF PUMP IS NOISY:

1. If motor is noisy, check motor bearings for wear

or lack of lubrication.

2. If pump is noisy, check basin for presence of

foreign material, inspect bearings for wear, see if

strainer is clogged.

3. If the flexible coupling connection is noisy, see

that

coupling

is

not

binding

and

that

motor

alignment is correct.

4. Rotate pump by hand to see if impeller is rubbing.

IF PUMP OPERATES AT BLOW OR VARIABLE

SPEED:

1. See that switch contacts are not arcing.

2. Test for loose connections.

3. If motor is three phase, see that all phases are

“live.”

4. Be sure the shaft rotates, freely, try turning by

hand.

5. Test motor, see if partially grounded.

6. Test service for low voltage.

7. Be sure motor is wired for the voltage used.

IF PUMP OPERATES BUT FAILS TO EMPTY SUMP:

WARNING

1. See if strainer is clogged and basin dirty.

2. Check rotation of pump.

3. See if check valve in discharge line is stuck.

4. Check discharge head, see if beyond pump rating.

5. Check basin; see if inflow is excessive.

6. See if shaft is intact and if the impeller rotates.

Check the flexible coupling connection.

7. Check to see if pump is air bound.

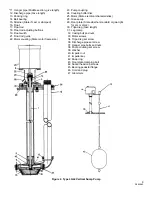

DISASSEMBLY:

Disassemble the sump pump in the

following manner (see figure 2):

Tie the disconnect switch open

or remove fuses from lines before attempting to

remove pump from the basin. Attach a card “DO

NOT CLOSE SWITCH – PUMP REPAIR IN

PROGRESS.” Disregard of this warning may result

in fatal electrical shock.

WARNING

1. Break the electric service and remove the motor,

disengaging the coupling (22) by gently prying the

buffer disc (24) off the pins so that the disc comes

off with the motor.

Do not work under a suspended

object unless there is a positive

support under it to stop its fall in event of sling or

hoist failure.

WARNING

2. Disconnect the pump discharge at the union,

remove floor plate bolts, and puss the pump out of

the sump basin.

3. Remove the assembly.

7

2899982