FLOOR MOUNTING:

A raised concrete foundation may

be provided for convenience of elevation, but it is not

required if the floor is level. If a concrete foundation is

provided it should be solid and rigid to support the

complete unit without deflection or vibration.

PIPING:

To facilitate and simplify piping, the volute

casing and discharge flange can be rotated to any one of

4 positions by removing the 4 adaptor-to-casing cap

screws and rotating to the desired position. Suction

piping should not contain any low points which can trap

air. When the pump is located above the level of the

water, a check-valve or foot valve should be installed in

the suction line to maintain prime, and a priming tee

should be so located at the discharge flange of the

pump that the case and suction line can be completely

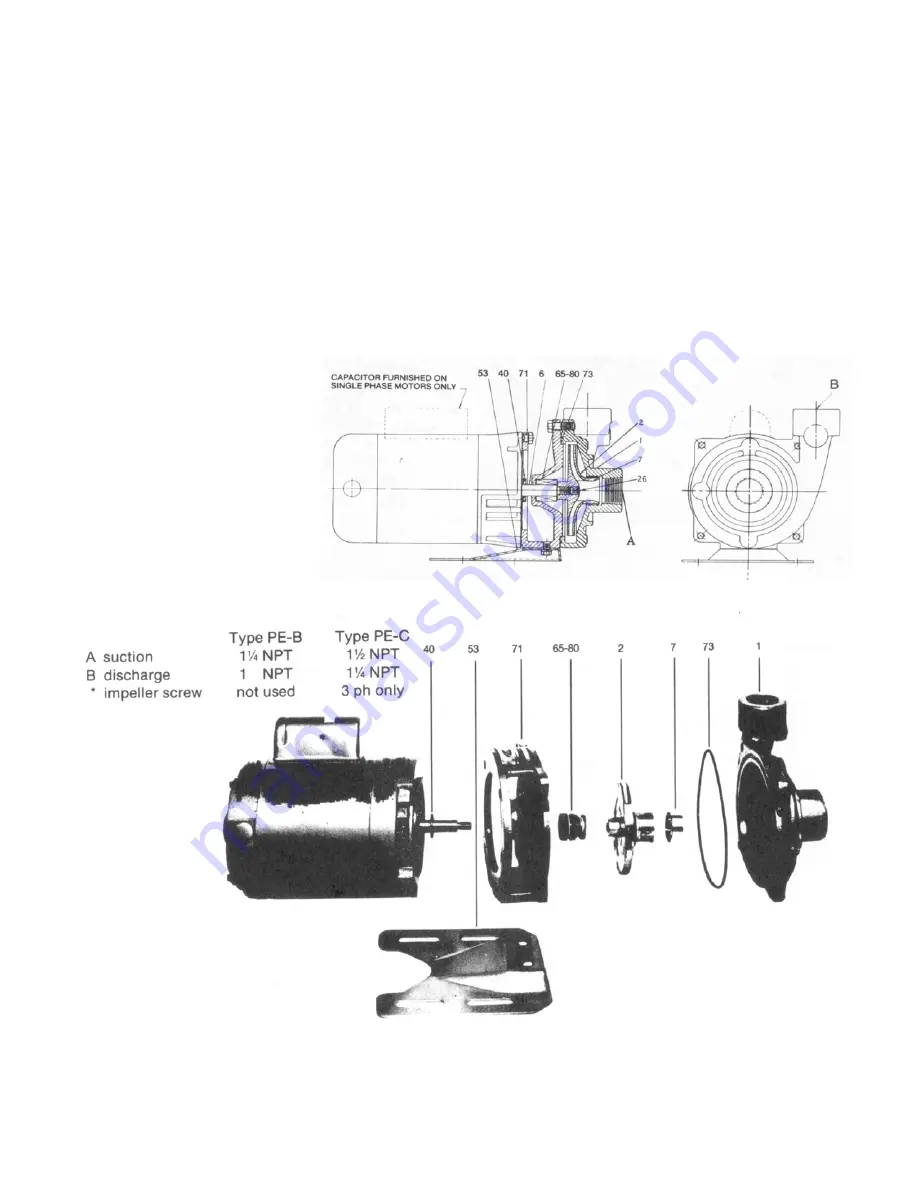

1 casing – cast iron

2 impeller – bronze

6 shaft – stainless steel

7 casing ring – bronze

*26 set screw – stainless steel

40 deflector – rubber

53 base – steel

71 adapter – cast iron

73 “o” ring seal

65-80 mechanical seal

2891096

filled. If debris is apt to be present, a combination foot-

valve strainer should be used. When the suction is under

pressure, or the level of the water is above the pump, a

valve and union should be installed in both the suction

and discharge pipes to permit inspection and service of

the pump at any time. To obtain optimum performance,

suction pipe joints must be made up with pipe joint

compound to insure that there are no air leaks. When

the pump is located above the liquid or operating with a

suction lift, even a small air leak in the suction line will

materially reduce capacity of the pump or cause a loss

of prime. If a union is required, use a gasket type and

seal it with pipe joint compound. Also, the pump must

not support heavy suction of discharge piping, and

piping must not be forced into place because this should

result in distortion and binding of rotating parts.

FIGURE 1. CLOSE COUPLED SERIES PE-B AND PE-C

3