CAUTION Make certain that the pump is free from

alignment, resulting in a possible binding of the

rotating element. Avoid springing the piping into line

and use caution when tightening the connections.

Provide a suitable means (other than the pump) to

support the weight of the suction and discharge

piping. It is important, particularly in new pipe lines,

that the piping is properly cleaned of all foreign

material. Failure to adhere to these precautions can

result in equipment damage and malfunction.

ELECTRICAL CONNECTIONS PE-B and PE-C:

Be

sure the motor terminals are connected for the voltage to

be used. Connection diagrams can be found on the

nameplate or inside the terminal cover. Single phase, ¼

and 1/3 horsepower motors are wired for either 115 volts

or 230 volts as desired; standard factory connections

you receive should be 230 volts. Three phase motors

may be of other voltage and are not pre-connected.

Local and national electrical codes governing wiring

should be observed.

MOTOR:

The motor supplied with the Peerless end

suction pump does not require lubrication – it is lifetime

lubricated. It may have a build-in overload protection

which will automatically reset as the motor cools,

therefore, the main switch should always be open when

working on the motor. If for any reason the motor is

serviced or reconditioned, its rotation should be checked

to be clockwise when looking toward the pump at the

end opposite the shaft extension. Also, this end of the

shaft, covered by a plug, has a screwdriver slot referred

to elsewhere for holding or turning the motor shaft,

pump, etc.

IMPELLER:

The impeller rotating in the pump casing is

the only moving part of a centrifugal pump. In case of

reduced pressure or reduced capacity requiring service

traceable to the impeller, its water passages should be

inspected by passing a flexible wire, etc., from the

outside toward the center to dislodge any obstructions.

See DISASSEMBLY as required for this operation.

MECHANICAL SHAFT SEAL:

A short run-in period may

be required when a new unit is placed in operation

before a perfect seal is effected in the mechanical shaft

seal. However, there should be no leakage at the seal

during normal operation. If considerable grit, etc., is

present in the water, the seal may eventually become

scored and develop a leak. In such case, the seal should

be disassembled and all parts cleaned thoroughly. The

rubber bellows should be examined for leaks and seal

faces for scratches. Worn parts should be replaced, but

emergency repairs may be made of the seal faces by

smoothing these on No. 500 grit Carborundum paper

placed on plate glass to provide a flat surface. See

DISASSEMBLY as required for this operation also.

2891096

PRIMING AND STARTING:

When the pump is located

above the level of the liquid , the pump must be primed

by filling the case and suction line through the tee in-

stalled at the discharge flange. Be sure all the air has

been expelled from the suction pipe and pump case.

CAUTION Prime pump before starting motor or

damage can occur to internal pump parts.

The rotation of single phase motors is predetermined by

internal wiring, but the rotation of 3-phase motors must

be checked at installation by momentarily closing the

electric service switch and observing the rotation. It

should be clockwise when looking toward the pump from

the free end of the motor. Interchange of any 2 of the 3

power leads will reverse a 3 phase motor.

DISASSEMBLY:

It is advisable that a competent pump

mechanic be employed for disassembly and reassembly

operations. Before starting disassembly or the pump, re-

check to make certain that this operation is necessary.

Close any valves that may be installed in the suction or

discharge piping.

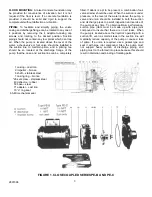

PE-B and PE-C:

See figure 1. Remove the 4 case-to-

adapter screws and the mounting foot-screws. This

permits removal as an assembly the motor, the adapter,

the foot, and the impeller. Remove casing O-ring (130).

The impeller (2) is now exposed for inspection and

cleaning. See paragraph on impeller. The impeller is

assembled to the motor shaft by 7/16-20 RH thread. On

3-phase, PE-C units, impellers are locked in place with a

7/16-20 hex socket set screw. If disassembly is

necessary, hold the motor shaft with a screwdriver,

engaging the slot which is covered by a cap at the

opposite end, remove the set screw, if provided, and turn

the impeller counterclockwise. The mechanical shaft

seal (65-80) can now be removed for inspection, service,

or replacement. Remove adapter (71) to motor frame

screws. Remove adapter. Slide deflector from shaft.

PB-B and PB-C:

See figure 2. Remove the 4 case-to-

adapter screws and remove casing (1) and casing O-ring

(130). The impeller (2) is assembled to the shaft by 7/16-

20 RH thread. Hold shaft (6) and turn impeller

counterclockwise for removal. The mechanical seal (65-

80) can now be removed for inspection, service or

replacement.

Remove adapter (71) to bearing frame screws. Remove

adapter. Slide deflector (40) from shaft. Remove snap

ring (16A) from groove in bearing bore on pump end side

of frame (19). Push shaft with bearings from frame.

4