TABLE 1

BEARING DEFECTS

(Failures – Replace if found)

DEFECT (Failure)

Flaking and cracking

APPEARANCE

In the early stages, the surface of the inner and

outer races develop small cracks, which flake.

The cracks and flaking ultimately spread over

the entire race surface.

PROBABLE CAUSE

1.

Normal fatigue failure.

2.

Bearing loads in excess of bearing capacity

caused by misalignment.

Indentations

Indentations or cavities in the inner and outer

races.

1.

Dirt in the bearings.

2. Excessive impact loading of the bearings

such as improper mounting or removal.

Broken separator (cage)

Cracked separator or separator in pieces.

1.

Poor Lubrication.

2.

Misalignment of shaft.

3. Excessive

shaft

deflection.

Wear

Bore and OD of outer ring of bearing galled or

braided.

1.

Fit on shaft or in housing too loose.

2. Bearing locked by dirt and turning on shaft

or in housing.

Fractured ring

Hairline cracks or complete ring fracture.

1.

Forcing a cocked bearing on or off a shaft.

2.

Too heavy a press fit.

Discoloration

Rolling elements and races darker than normal

appearance of bearing metal.(Moderate

discoloration of rolling elements and races not

a reason for discard.)

1. Inadequate lubrication.

Corrosion

Rolling elements and raceways rusted.

1.

Water entering the housing.

2.

Condensation inside the housing.

3.

Lubricant breaks down into acid. (Wrong

lubricant.

pump) and push the bushings (63) to the rear of the stuffing

boxes. Insert the same number of packing rings as were

found during disassembly, on each side of the lantern ring

Insert each ring separately and stagger the joints of

successive rings 90 degrees. Insert the glands (17) and set

the nuts finger tight – DO NOT USE A WRENCH.

h. Rotate shaft by hand to check that it runs free.

i. Replace all drain plugs removed during disassembly.

3-3. Reinstall plumbing (if used) for water-cooled bearings.

a. Re-lubricated the bearings. Refer to Bulletin No. 2880549

for grease type recommendation.

It is most important to provide proper lubrication and keep

bearings clean. Frequency of lubrication must be determined

by experience as it depends upon bearing size, speed,

operating conditions and location (environment). Table II

should be used as a guide for grease re-lubrication. Oil

bottles should have a visible supply at all times.

b. Oil. (Pumps are shipped without oil in the bearing

housings.) Be sure to fill and adjust constant level oilers

before initial start of pump. See Figure 9.

(1) Adjust dust cap to lowest possible position on base

fittings.

(2) The pipe nipple and base fitting must be level – check

with spirit level. If the pipe nipple is bent, replace it. A

constant level oiler that is not level will not provide proper

lubrication to the bearings.

(3) Fill bottle, screw it into the dust cap as far as it will go-

do not force. Allow the oil to flow into the bearing housing.

Repeat this procedure until there remains a supply of oil in

the bottle. Never fill bearing housing through base fitting.

(4) Check the breather tube for cleanliness. The breather

tube must be used with the oil lubrication system.

3-4. Follow instructions in Bulletin No. 2880549 to check out

the pump after repair and place the pump in service.

2883819

LUBRICATION INSTRUCTIONS

1. The pump is shipped without oil in the

bearing housings.

2. Change the first oil after operating 1000

hrs. or 60 days, whichever occurs sooner.

3. Frequency of oil change thereafter is

dictated by service conditions, It is

suggested, however, that oil changes

occur at least every 3,000 hrs. of operation.

4. In order to keep the bearing housings

vented, the breather tubes and filters

must be kept clean.

Lubrication Oils

A high quality turbine oil of 330 SSU viscosity at 100 degrees F.

with rust and oxidation inhibitors should be used.

RECOMMENDED OIL MANUFACTURERS

Atlantic Richfield

DURO S-315, DURO AW S-315

Chevron

CHEVRON OC TURBINE OIL 68

Exxon TERESSTIC

68

Gulf

GULF HARMONY 68

Mobil

DTE 26 300SSU

Sunoco SU VIS

968

N

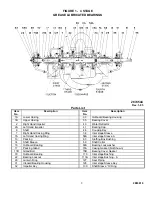

FIGURE 9

3-5. TROUBLES. To reliably establish the malfunctioning of

either the pump or driver, instruments such as tachometers,

pressure gauges and electric meters must be in proper

working condition and preferably of recent calibration. In

many cases, much time and expense have been expended

with faulty instruments. Table V lists a number of troubles

commonly occurring. If unable to determine the cause and

remedy the problem from this list, refer the problem to the

Peerless Pump Company representative.

10