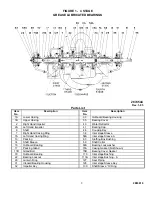

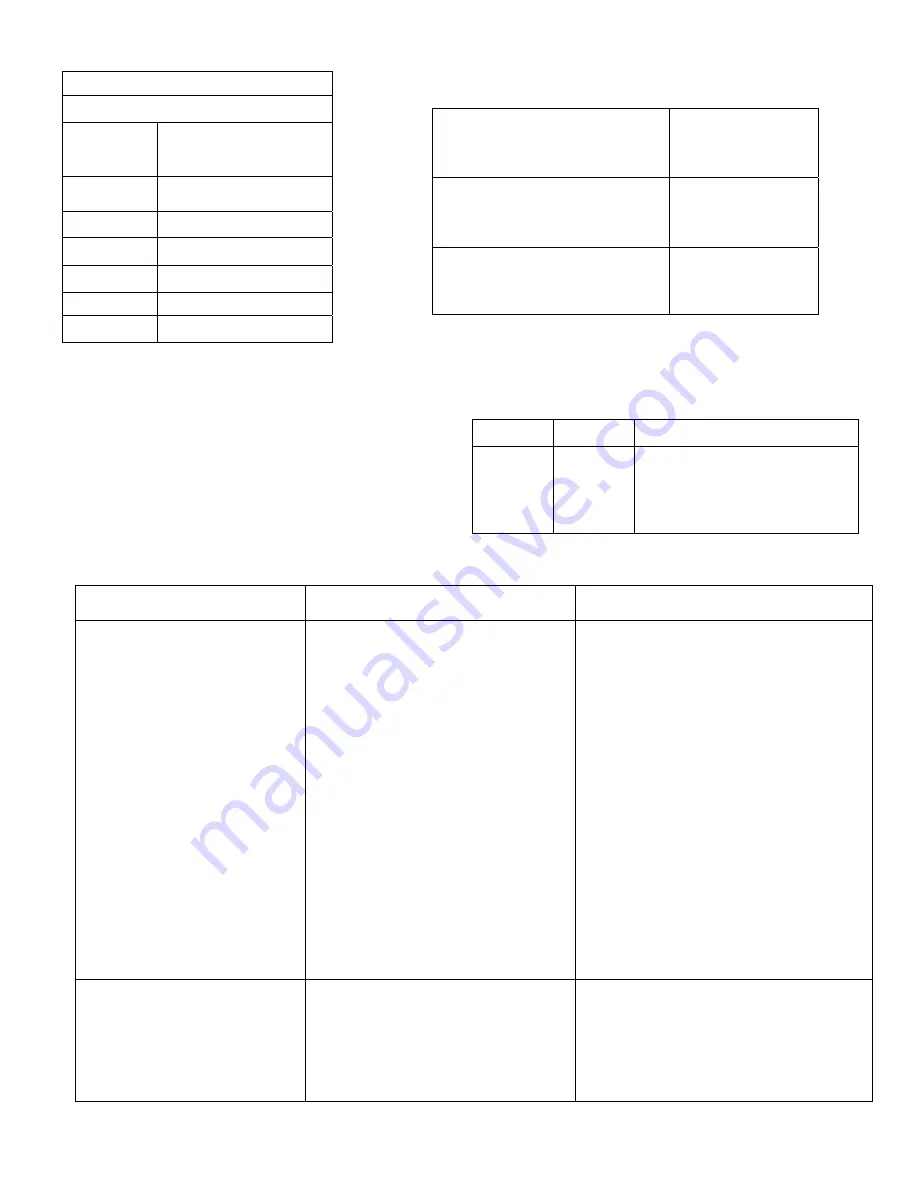

Table II TABLE III

GREASING FREQUENCY

(See Table IV for amounts)

TORQUE VALUE CHART

TORQUE VALUT (FT.-LB)

SIZE

INCH

MEDIUM CARBON

STEEL. SAE 5

105-120,000 PSI

3/4

210-225

7/8 305-325

1 450-475

1-1/8 605-635

1-1/4 850-890

1-1/2 1465-1525

SERVICE

Normal, 8-hour day operation,

Room free of dust and damage-

ing atmosphere.

GREASE EACH

6 Months

Severe, 24-hour day operation.

Room with moderate dust

And/or damaging atmosphere,

or outdoor service.

1 Month

Light, approximately 10-hour

week. Room relatively free of

dust and damaging atmosphere.

1 Year

TORQUE VALUES SHOWN ARE FOR

TABEL IV

CLEAN & LUBRICATED THREADS:

AMOUNT OF GREASE

GASKETED JOINTS.

FOR BALL BEARINGS

STUDS MUST BE DRIVEN TIGHT IN

LOWER WHEN USED.

INSTALL UPPER CASE, TIGHTEN CENTER

NUT (OR CAP SCREWS), THEN WORK OUT

FROM CENTER TO EACH SIDE. TIGHTEN-

ING WITH TORQUE WRENCH AS SHOWN

ON CHART.

TABLE V

TROUBLES

TROUBLE

PROBABLE CAUSE

REMEDY

Failure to deliver liquid or sufficient

pressure.

Pump not primed.

Pump not up to speed.

Discharge head too high.

Insufficient available NPSH.

Incorrect direction of rotation.

Air leaks in suction line or through stuffing

boxes.

Impeller passages restricted

Worn wearing rings.

Damaged impeller.

Foot valve too small or restricted by dirt.

Re-prime.

Check for low motor voltage or motor over-

load. Other drives, increase driver speed

when possible.

Check to see that all discharge valves are

opened and the discharge line is free from

obstructions. In some cases, the installation

has to be altered or a pump of suitable rating

must be provided.

Check NPSH requirements of pump and

increase system NPSH accordingly.

Check the impeller assembly for correct rotation

either by removing upper case or through

priming connection. Check rotation of driver.

Tighten packing. Check for air leaks between sleeve

and shaft and replace O-ring if there is an air leak.

Check all suction line joints

For bad gaskets and loose joints.

Disassemble the pump and clean impeller.

Replace worn parts.

Replace or repair impeller.

Replace with adequate size foot valve or clean

foot valve.

Pump loses prime after starting

Air leaks in suction line.

Insufficient available NPSH

Tighten packing. Check for air leaks between

sleeve and shaft and replace O-ring if there

is an air leak. Check all suction line joints

for bad gaskets and loose joints.

Check NPSH requirements of the pump and

increase the system available NPSH

accordingly.

2883819

OUNCES

GRAMS MODEL

1.3

1.4

3.0

4.5

36.4

39.2

84.0

126.0

1 1/2TUT7, 1 1/2TUT7G4,

2TUT8, 2TUT8A4, 2TUT9,

2TUT9A5,3TUT9, 3TUT9A4,

4TUT10, 4TUT10A4,

4TUT10G4

11