1-5.

CLEANING BEARINGS

a. Remove bearings from the housings, referring to dis-

assembly instructions.

b. Place bearings in a wire basket, so there is space

for the cleaning solvent to reach all parts.

c. Immerse the basket in Stoddard solvent or

equivalent, agitating the basket until grease is

thoroughly loosened and can be flushed out.

2-1.

INSPECTION.

Visually inspect parts for damage

affecting serviceability or sealing. Emphasize

inspection of mating parts having relative motion –

wear rings, for example. Perform detail inspection as

follows:

a. Check O-rings and bearing cover gaskets for

cracks, nicks or tears; packing rings for excessive

compression, fraying or shredding, embedded particles

(dirt or metal). Replace if defective in any way.

b. Mount the shaft between lathe centers. Check the

eccentricity trough out entire length with a dial indicator

to be not more than .003 inch total indicator reading.

Check that threads are clean and sharp. Surfaces on

which bearings mount must be smooth, have a finish

not less than 32 micro-inches, and have shoulders

square and free from nicks.

c. Measure the OD of the integral impeller wear

surfaces and the ID of the casing rings (7 and 7A).

Compute the diametrical clearance (ID minus OD) and

compare with the limit given in Figure No. 5. ID surface

of casing ring must be smooth and concentric. For

pumps equipped with impeller rings, clearances should

not exceed two times the maximum amount shown for

pump type in Figure No. 5.

d. Measure OD of inter stage sleeves (58, 58A)

(balancing disc (56) and ID of inter stage bushings

(113, 113A). Compute diametrical clearance and

compare with limits given in Figure No. 6. ID surface of

inter stage bushing must be smooth and concentric.

Sleeve lands must be free from burrs and flat spots.

e. Examine impeller passages for cracks, dents,

gouges or embedded material.

f. Check upper and lower casing machined surfaces to

be free of burrs or nicks.

g. Inspect shaft sleeves (14) for excessive wear.

h. Inspect bearings according to Table I.

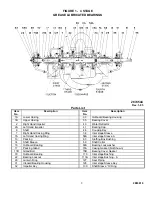

FIGURE 5

2883819

d. Place bearing on a screened surface.

e. Using a spray gun with air filter and clean Stoddard

solvent, flush each bearing until all grease and sludge

is removed.

f. Blow solvent out of bearings with dry filtered air.

g. Lubricate bearings immediately after cleaning with

light spindle oil and place them in a covered container.

h. Do not spin bearings any time during cleaning.

2-2.

REPAIR.

Make needed repairs in the following

manner:

a. If ID of casing ring (7, 7A) is grooved, scored or

eccentric, bore to produce a smooth, concentric

surface, replacement of casing ring and impeller ring is

recommended. Measure and record the new ID.

b. If impeller rings are defective, or mating casing rings

require boring, remove old rings by turning in a lathe –

be sure machining is concentric with impeller ID. Use

care NOT to reduce hub OD.

NOTE

For bronze impellers and rings, the ring is shrunk on

the hub according to standard fit FN-4 or ANSI B4.1

standards. For pumps of 10-inch discharge and larger,

the rings are also tack welded to the hub at 3 places

120 degrees apart. Hardened impeller rings are

installed according to ANSI B4-1 standard fit FN-1.

c. Install new rings on the impeller (shrink or press

depending on material and tack weld if old rings were

tacked. This ID is factory – machined for proper fit.

d. Turn the OD of the new rings to provide the proper

diametrical clearance and to be smooth and concentric

with hub bore. Use clearance limit from Figure No. 5

and ID of casing ring from paragraph 2-2a. to compute

OD of impeller rings.

e. Replace worn shaft sleeves.

f. Straighten or replace shaft having excessive run-out

(eccentricity).

INTERSTAGE SLEEVE/BUSHING

DIAMETRICAL CLEARANCE (inches)

0.008

0.012

0.012

0.015

1-1/2TUT74,1-1/2TUT7G4, 2TUT8-4,

2TUT8A4, 3TUT9-4 ,3TUT9A4

2TUT9-5

2TUT9A5

FIGURE 6

NOTE

Clearances are for standard or cast iron fitted pumps.

For materials with a tendency to gall, such as stainless

steel, increase clearance approximately .010 inch.

IMPELLER/CASE WEAR RING

DIAMETRICAL CLEARANCE (inches)

0.010

0.014

0.012

0.016

0.023

0.027

1-1/2TUT74

1-1/2TUT7G4

2TUT8-4

2TUT8A4

3TUT9-4

3TUT9A4

4TUT10-4

4TUT10A4

4TUT10G4

2TUT9-5

2TUT9A5

SECTION II

INSPECTION AND REPAIR

8