Figure 8. Simplex Moisture Detection Controller

INSTALLATION, OPERATION AND MAINTENANCE

INSTRUCTIONS FOR MOISTURE DETECTION

CONTROLLER

General

The Moisture Detection Controller is a conductance

actuated control for detecting moisture in the oil chamber

of a submersible pump motor. It is used as a warning

device to indicate a seal leakage and to signal the need

for preventative maintenance.

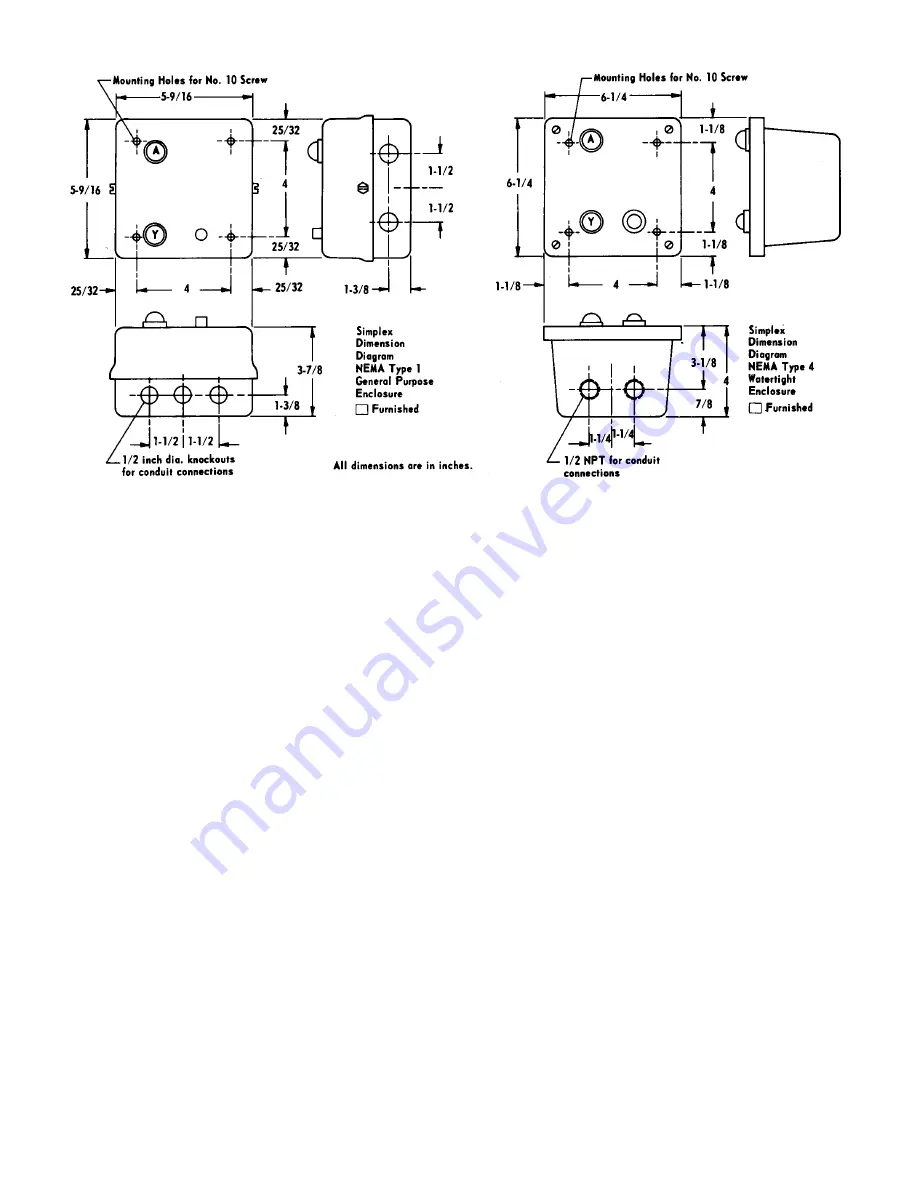

Installation

Mount control box vertically on wall or other solid

structure and accomplish all indicated wiring. Terminals

on the control are numbered and are in the same relative

position as shown on the wiring diagram. Terminal pair

1-2 must be continuously energized form an A.C. supply

line of electrical characteristics shown on the data

plate. Contacts 5-6 and/or 7-8 are available for load

duty, and if required, must be wired in Series with the

load device or devices, and that series branch circuit

connected across a power source compatible with the

load. Terminals 9-10 are connected to the moisture

sensing probes in the motor marked W1-W2 via the

cable provided with the motor.

Operation

Normally the oil surrounding the probes is nonconductive,

and the control and seal leakage indicator light will be de-

energized. An influx of moisture past the outer seal and

into the oil reservoir will change the conductivity of the

Oil and this condition will cause the relay to energize,

and the seal leakage light will energize to indicate a seal

leakage. Load contacts 5-6 and/or 7-8 will also change

from their normally open or normally closed position when

the control energizes.

Test Procedure

A normally closed pushbutton and neon indicating lamp

are provided as a part of the control for testing the

moisture sensing components. The motor manufacturer

has provided a 330,000 ohm resistor across the probes

inside the motor to complete the test. When the test

pushbutton is depressed, the neon indicating lamp will be

illuminated to indicate: (a) Power is supplied to the control.

(b) The control is operative.

(c) The wiring to the moisture

sensing probes in the motor is intact.

This check does not simulate a leakage. An ad-

ditional check can be made by removing the enclosure

cover and momentarily placing a jumper (or 20,000 ohm

resistor) across terminals 9-10 on the control. This will

energize the control, and test out the neon indicating

lamp and associated voltage dropping resistor across

terminal 2 and 4.

CAUTION: Voltage will be present at all terminals on

the control when this test is being made.

10

2899213