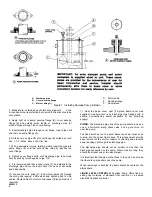

A. Discharge

pipe

B.

Cover packing flange

C. Motor

cable

grip

3. Break sharp, outside edge of discharge pipe with a file.

A rounded corner is preferred, but a smooth chamfer should be

acceptable.

4. Apply light oil to pump packing flange (E), cover packing

flange (B) and outside entire length of discharge pipe (A)

which will pass through the cover packing.

5. Insert discharge pipe through cover flange, lower pipe until

end rests on pump flange (E).

6. Scribe a line on pipe OD at cover flange (B) scribe a second

line 1-1/2 inches above the first line.

7. With a downward turning, twisting motion insert the pipe into

pump flange (E) until the second line (step 6) reaches the

cover flange.

8. Tighten cover flange bolts until discharge pipe is securely

held by packing forced against pipe OD.

9. It is recommended that a spool piece (F) be installed in the

discharge pipe above the basin cover for ease of assembly

and disassembly.

10. Loosen the cord grips (C). Pull motor cables (D) through

the cord grips leaving a little slack and tighten grips to hold

cables. Route cables to motor control panel (through conduit, if

required).

2899213

4

D. Motor cable

E. Packing

flange

F. Spool

piece

Figure 1. Installing Sewage Pump in Basin

11. Seal the basin cover split (if 2-piece basin cover was

supplied), manhole cover and discharge pipe flanges with a

pliable, non-hardening sealer (available at any plumbing

supply).

PIPING:

The discharge pipe line of the pump should include a

union, a horizontal swing check valve, and a gate valve, all

near the pump.

The line should be run to a point above the sewer level so as

to drop into the sewer from above. This arrangement permits

easy removal of the unit for repairs or cleaning and prevents

sewer backing up through the discharge pipe.

The discharge pipe should not be smaller in size than the

discharge connection on the pump. Where runs are long, they

should be at least one or two sizes larger.

It is important that the pipe connections to the unit be so made

that there is no pipe strain upon the pump.

When raw swage is handled, the basin should be vented to the

atmosphere.

LIQUID LEVEL CONTROLS:

Peerless Pump offers fixed or

sliding float versions of standard float controls, or, a sealed

electrode floatless controller,