ISSUED: 08-08-08 SHEET #: 055-9094-1

Visit the Peerless Web Site at www.peerlessmounts.com

For customer care call 1-800-865-2112 or 708-865-8870.

10 of 16

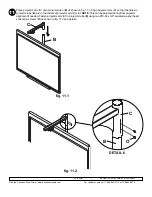

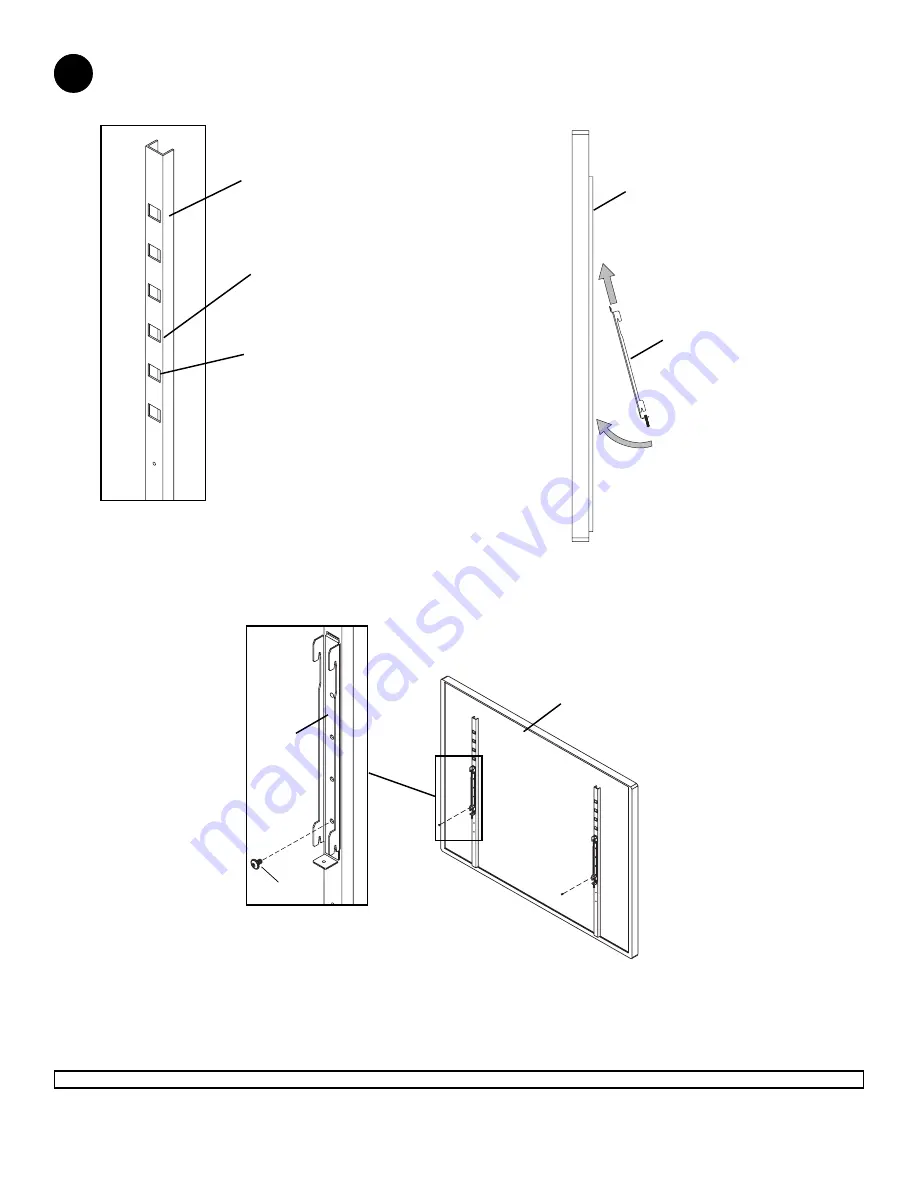

Insert hook brackets into screen as shown in detail 2 and fig. 7.1. Secure each hook bracket (

E

) with M6 x 12 mm

serrated washer head socket pin screw (

L

) as shown in fig. 7.2 and detail 3.

7

DETAIL 3

fig. 7.2

E

L

SCREEN

SCREEN

E

fig. 7.1

77" SCREEN

63" SCREEN

DETAIL 2

SCREEN

BRACKET