Visit the Peerless Web Site at www.peerlessmounts.com

ISSUED: 03-26-09 SHEET #: 125-9060-5 07-26-13

Refer to

Screen Compatibility Chart

to determine the proper fastener to use. Visit

www.peerlessmounts.com/2

for a full screen compatibility chart for this mount.

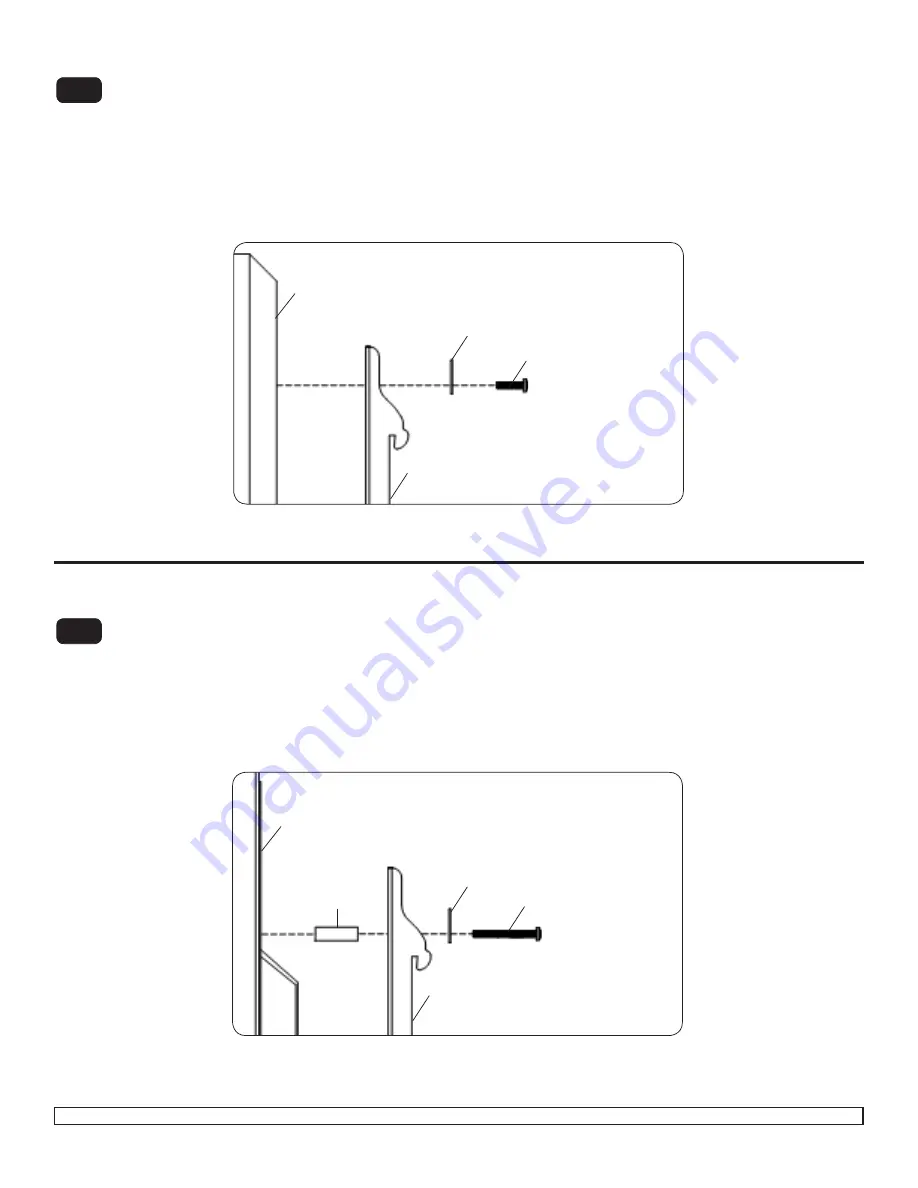

Begin with the shortest length screw, hand thread through multi-washer and adapter bracket (

C

) into screen as

shown below. Screw must make at least three full turns into the mounting hole and fit snug into place. Do not over

tighten. If screw cannot make three full turns into the screen, select a longer length screw from the baffled fastener

pack. Repeat for remaining mounting holes, level brackets and tighten screws.

NOTE:

Spacers may not be used, depending upon the type of screen.

Refer to

Screen Compatibility Chart

to determine the proper fastener to use. Visit

www.peerlessmounts.com/2

for a full screen compatibility chart for this mount.

Begin with longer length screw, hand thread through multi-washer, adapter bracket (

C

) and spacer in that order

into screen as shown below. Screw must make at least three full turns into the mounting hole and fit snug into

place. Do not over tighten. If screw cannot make three full turns into the screen, select a longer length screw from

the baffled fastener pack. Repeat for remaining mounting holes, level brackets and tighten screws.

For Flat Back Screen

For Bump-out or Recessed Back Screen

SCREEN

fig 4.2

ADAPTER BRACKET (

C

)

SCREEN

fig 4.1

MULTI-WASHER

SCREW

4-2

4-1

If you have any questions, please call Peerless customer care at

1-800-865-2112

.

If you have any questions, please call Peerless customer care at

1-800-865-2112

.

MULTI-WASHER

ADAPTER BRACKET (

C

)

SCREW

SCREEN

SPACER