4 of 9

ISSUED: 03-02-11 SHEET #: 125-9192-1

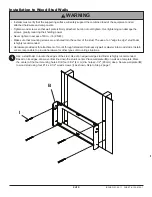

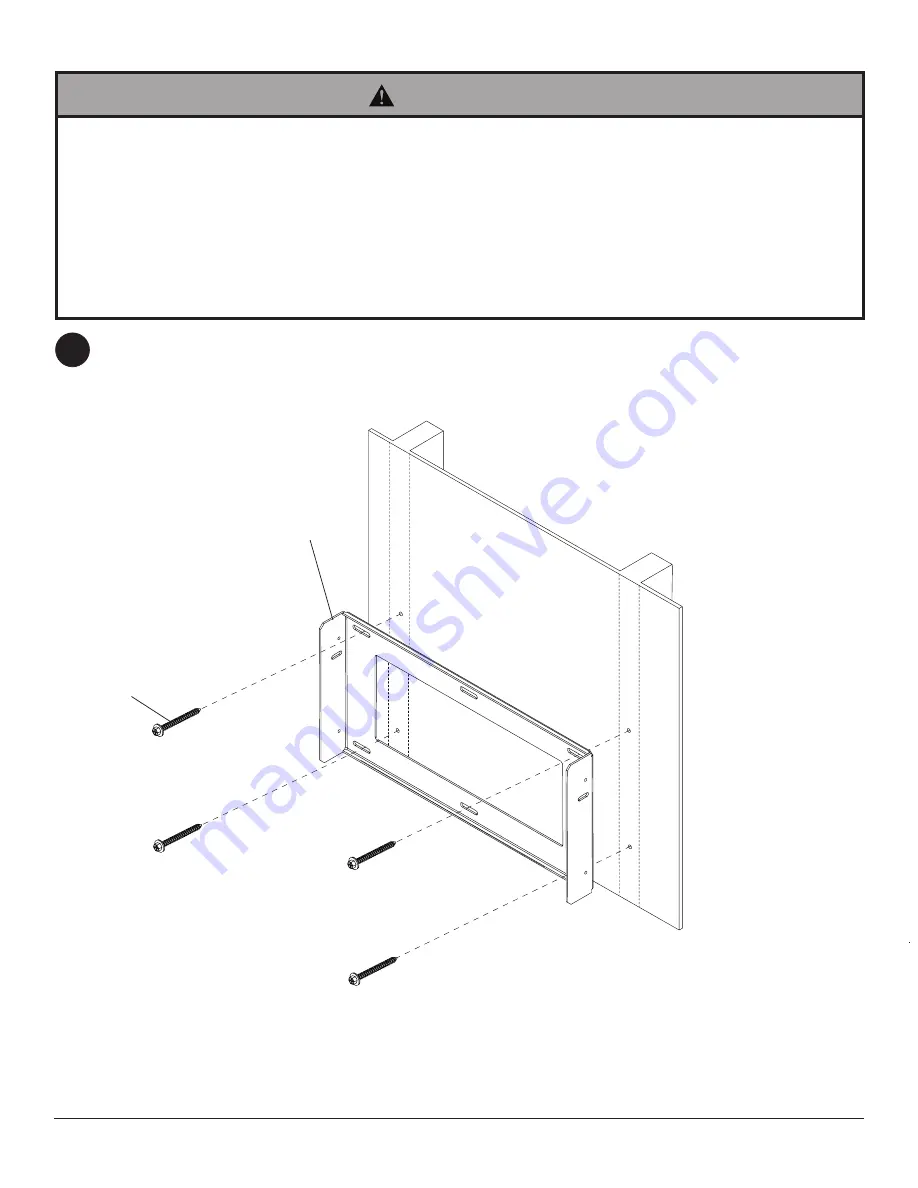

B

I

Installation to Wood Stud Walls

Use a stud finder to locate the edges of the stud. Use of an edge-to-edge stud finder is highly recommended.

Based on its edges, draw a vertical line down the stud's center. Place wall plate (

B

) on wall as a template. Mark

the center of the four mounting holes. Drill four 5/32" (4 mm) dia. holes 2-1/2" (65 mm) deep. Secure wall plate (

B

)

to wood stud using four #14 x 2-1/2" wood screws (

I

) as shown. Skip to Step 2 page 7

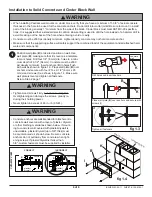

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

• Tighten wood screws so that wall plate is firmly attached, but do not overtighten. Overtightening can damage the

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Make sure that mounting screws are anchored into the center of the stud. The use of an "edge to edge" stud finder

is highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall or plaster into wood studs. Install-

ers are responsible to provide hardware for other types of mounting situations.

WARNING

1