6 of 9

ISSUED: 03-02-11 SHEET #: 125-9192-1

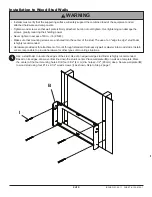

Position wall plate (

B

) at desired position on wall

.

Use

wall plate (

B

), making sure that it is level, as a template

to mark holes. Drill four 1/4" (6 mm) dia. holes to a mini-

mum depth of 2-1/2" (64 mm). Concrete must be 2000

psi density minimum. Insert anchors (

K

) in holes flush

with wall as shown in figure 1.3. Place wall plate (

B

) over

anchors and secure with four #14 x 2-1/2" (6 mm x 65

mm) wood screws (

I

) as shown in figure 1.4. Make sure

wall plate is level and tighten all fasteners.

Skip to Step 2 page 7

Installation to Solid Concrete and Cinder Block Wall

1

CUT

AW

AY

VIEW

INCORRECT

concrete

plaster/

dry wall

B

CORRECT

concrete

plaster/

dry wall

B

concrete

wall

Drill holes and insert anchors

Place wall plate (

B

) over anchors and secure with

screws (

I

)

Tighten all fasteners

I

B

1

2

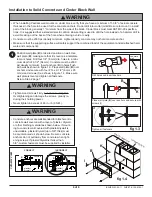

• Tighten wood screws firmly, but do not overtighten.

Overtightening can damage the screws, greatly re-

ducing their holding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

WARNING

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete

thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a solid

part of the block, generally 1" minimum from the side of the block. Cinder block must meet ASTM C-90 specifica-

tions. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a hammer drill to

avoid breaking out the back of the hole when entering a void or cavity.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached hard-

ware and components.

WARNING

K

K

I

K

fig 1.3

fig 1.4

• Concrete anchors are

not

intended for attachment to

concrete wall covered with a layer of plaster, drywall,

or other finishing material as shown below. If mount-

ing to concrete wall covered with plaster/drywall is

unavoidable, plaster/drywall (up to 5/8" thick) must

be counterbored as shown below. Be sure concrete

anchors do not pull away from concrete when tight-

ening screws. If plaster/drywall is thicker than

5/8", custom fasteners must be supplied by installer.

WARNING

CINDER

BLOCK

SOLID

CONCRETE

B

3