56

b. The default address for each boiler is “0”

c. Selecting a boiler address of “1” assigns the boiler

as the master. Be sure that this is the boiler that

is connected to the system pumps and external

sensors.

d. Once a boiler is configured as the master boiler,

a menu containing all cascade options listed

in Table 8.31 will be displayed. The remaining

options are intended to operate well with most

boiler systems using the default parameters.

However, the descriptions below allow the

experienced installer or service person to

modify the operation of the cascade system if

improvements are warranted

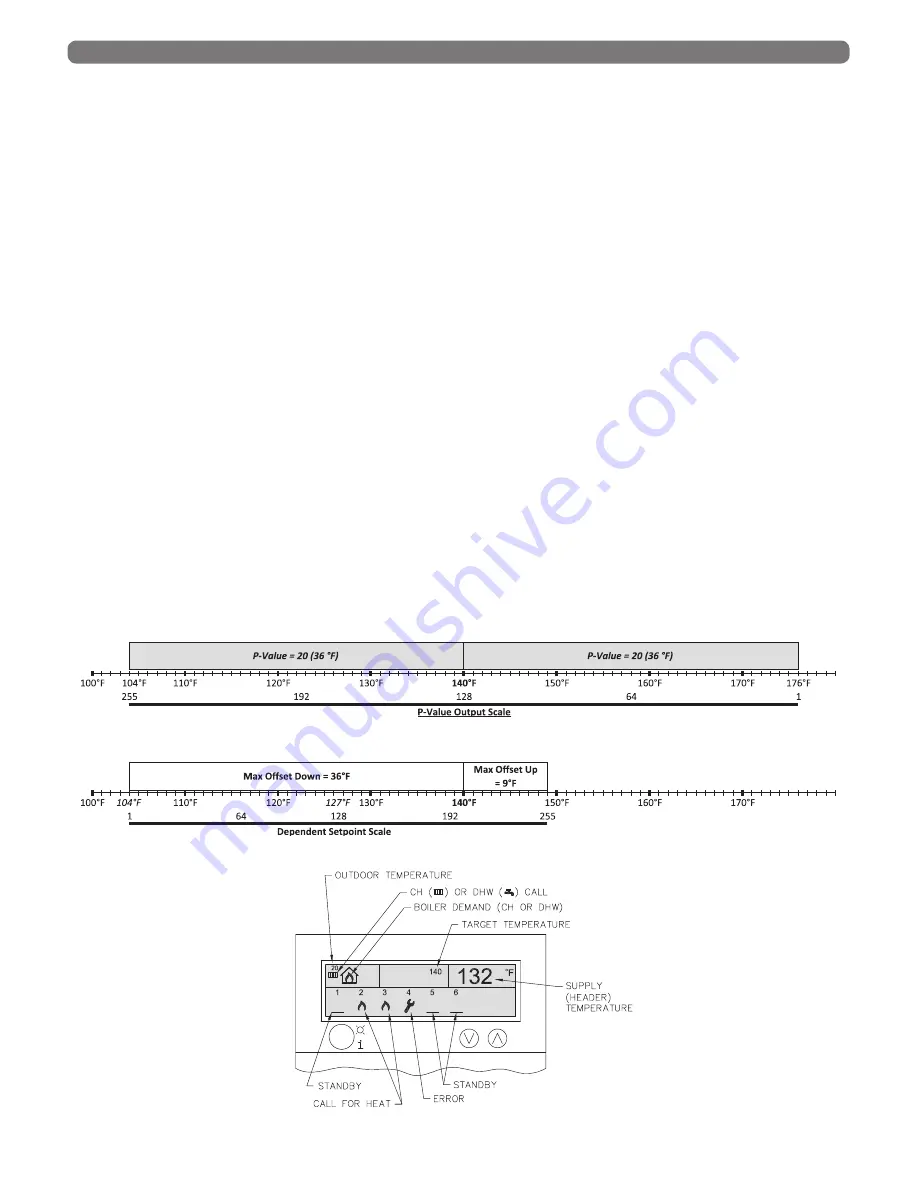

e) Figures 8.55 and 8.56 show how the P-Value,

Max Offset Up and Max Offset Down values affect

the dependent boiler setpoints.

i) The graphs illustrate the default values for the

control with a target temperature of 140°F.

ii) The control scales the actual supply

temperature to a 1-255 scale in the range

defined by the target temperature and the

P-Value. From Figure 8.55 we can see that

if the supply temperature is above 176°F the

output from the P-Value will be 1.

iii) Conversely, if the supply temperature is

below 104°F the output from the P-Value will

be 255. At any point within the range, the

P-Value will be scaled. As an example, if the

supply temperature is at the 140°F setpoint the

scaled value will be 128.

f) Figure 8.56 illustrates the range defined by

the

Max Offset Down

and

Max Offset Up

parameters.

i) If the output from the P-Value is 1, the

dependent setpoint will be set to the minimum

value (104°F in this case).

ii) If the output from the P-Value is 255, the

dependent setpoint will be set to the maximum

value (149°F).

iii) From the previous example, the output

value from a supply temperature of 140°F

yields a value of 128. Transferring this value

to the dependent setpoint scale indicates

that the dependent boiler setpoints will be

approximately 127°F.

g) The I-Value determines how quickly the setpoint

changes. Larger values result in a slower response

time and smaller values decrease the response

time.

h) The Slew Rate limits the rate of change in

dependent boiler setpoint. In this case, a larger

value allows a faster change in setpoint while a

lower value limits the rate of change.

3)

Cascade Display:

When the master boiler has

no heat demand, there is no heat demand to the

system. Therefore, each boiler in the cascade will read

“CASCADE BOILER #” followed by its boiler address.

a) The master boiler will display, “CASCADE

BOILER #1”.

b) Pressing the down arrow will display the cascade

system information including the master supply

sensor temperature and the status of all boilers

with which it is communicating. See Figure 8.57

for the cascade status screen illustration.

Figure 8.55: P-Value Output

Figure 8.56: Dependent Setpoint

BOILER CONTROL: OPERATION

Figure 8:57: Cascade Status Screen

Summary of Contents for PUREFIRE PFC-1000

Page 1: ...PUREFIRE Boilers PFC 850 PFC 1000 PFC 1500 Gas Installation Operation Maintenance Manual ...

Page 82: ...80 Figure 13 4 Control System REPAIR PARTS ...

Page 84: ...82 Figure 13 5 Condensate System REPAIR PARTS ...

Page 90: ...88 APPENDIX C USER MENU APPENDIX C USER MENU Figure C 1 User Menu Managing Burner ...

Page 91: ...89 APPENDIX C USER MENU Figure C 1 User Menu Dependent Burner ...

Page 92: ...90 APPENDIX D INSTALLER MENU STRUCTURE APPENDIX D INSTALLER MENU STRUCTURE ...

Page 93: ...91 APPENDIX D INSTALLER MENU STRUCTURE ...

Page 95: ...93 SERVICE LOG SERVICE LOG Date Serviced By Description of Service Serial Number ...

Page 96: ...94 NOTES ...

Page 97: ...95 NOTES ...