Boiler Control Instruction & Operation Manual, Rev 1

Page

27

of 64

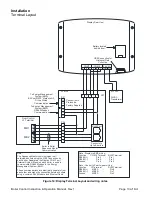

Installation

Energy Management Interface

Table 8: Modbus Signal List (continued)

Modbus

Register

Protocol

Name

Description

Read (R)/

Write (W)

Trouble Shooting

10,034

Lockout code

Reasons for burner lockout

0

No lockout,

4

Supply high limit

5

DHW high limit

6

Stack High limit

12

Flame detected out of sequence

18

Lightoff rate proving failed

19

Purge rate proving failed

20

Invalid Safety Parameters

21

Invalid Modulation Parameter

22

Safety data verification needed

23

24VAC voltage low/high

24

Fuel Valve Error

25

Hardware Fault

26

Internal Fault

27

Ignition Failure

R

10,040

Hold code

Reason for burner hold

0

None

1

Anti short cycle

2

Boiler Safety Limit Open

3

Boiler Safety Limit Open, (ILK Off)

7

Return sensor fault

8

Supply sensor fault

9

DHW sensor fault

10

Stack sensor fault

11

Ignition failure

13

Flame rod shorted to ground

14

Delta T inlet/outlet high

15

Return temp higher than supply

16

Supply temp has risen too quickly

17

Fan speed not proved

23

24VAC voltage low/high

25

Hardware Fault

27

Ignition Failure

R

Statistics

763

Modbus command

timeout

This parameter sets the amount of time the control will

wait for input from the Building Automation System

(BAS). If the BAS does not write to the following

register within the

“Modbus Command timeout”

seconds the following inputs are considered invalid:

CH Modbus Stat,

CH Modbus Setpoint,

CH Sequencer Modbus Setpoint

CH Modbus Rate

range 30

– 120, Default 30 seconds

Other R/W registers should only be written when a

value is needed to be changed. Only the above listed

registers are stored in non-volatile registers.

R/W