29

A. GENERAL

1. The disposal of all condensate into public sewage

systems is to be in accordance with local codes and

regulations. In the absence of such codes, follow these

instructions.

L’élimination de tout condensat dans les systèmes

d’évacuation publics des eaux usées doit s’effectuer

conformément aux codes et règlements en vigueur.

Si ces codes font défaut, suivre alors ces instructions.

2. Proper piping and removal of condensation from

combustion is critical to the operation of a condensing

appliance. Follow these instructions carefully to assure

that your Series PFC

TM

boiler operates correctly.

Pour le bon fonctionnement d’un appareil à

condensation, l’installation d’une tuyauterie adéquate

et la bonne évacuation de la condensation de la

combustion sont indispensables au fonctionnement

d’un appareil à condensation. Suivre attentivement

ces instructions pour assurer le fonctionnement

optimal de la chaudière Series PFC

TM

.

3. Depending on several factors, the condensate from

gas fired condensing appliances may have a pH value

as low as 2.5 (similar to cola soft drinks). Some local

codes require the use of neutralization equipment to

treat acidic condensate.

B. CONDENSATE SYSTEM

1. The condensate system for Series PFC

TM

boilers

perform the following functions:

a. Prevent condensate from backing up into the heat

exchanger.

b. Trap the condensate to prevent combustion gases

from escaping.

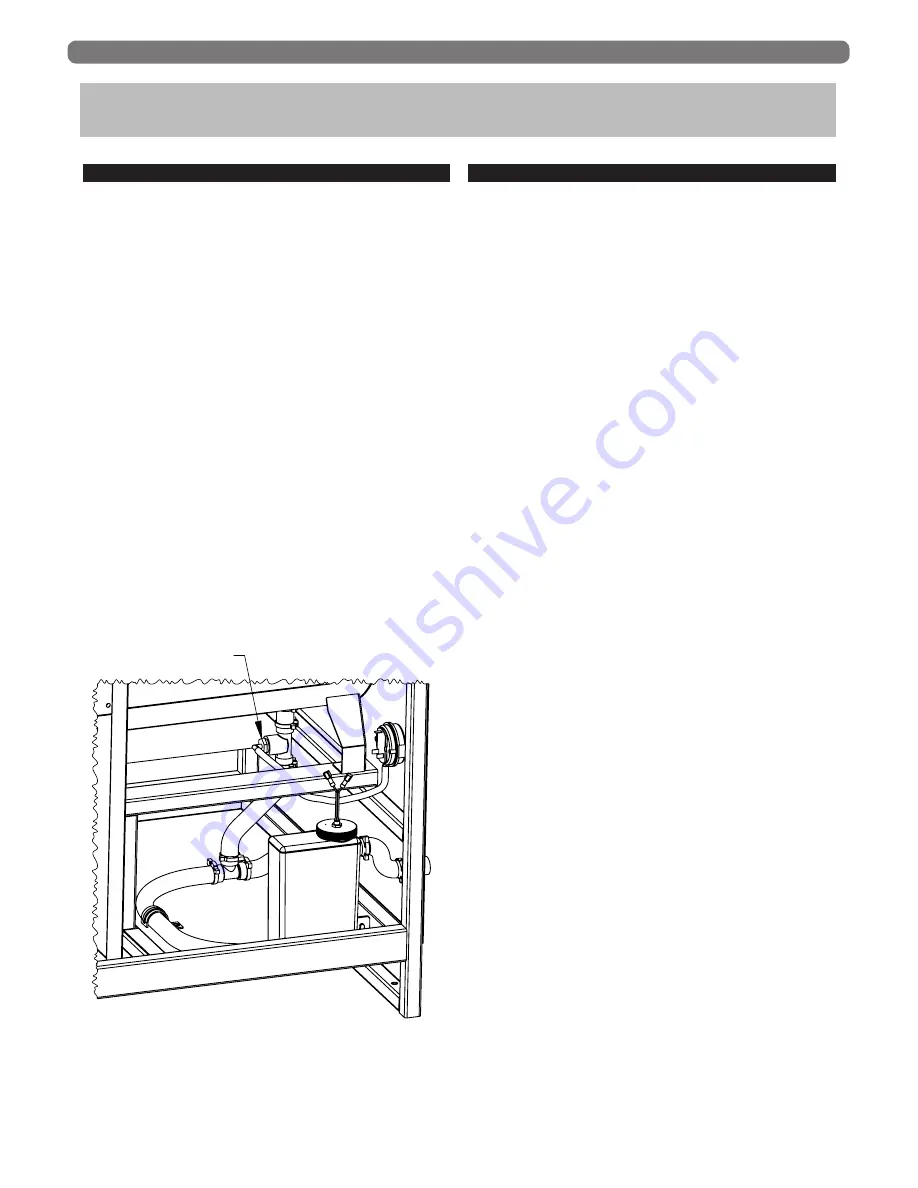

2. Figure 6.1 shows the components of the condensate

system.

a.

Condensate Collector Container

: This vessel is a

transparent plastic container designed to catch the

condensate separately from the heat exchanger

and from the exhaust venting system. This vessel

also acts as part of the trap to prevent combustion

gases from escaping. The container is fitted with a

blocked condensate float switch.

b.

Blocked Condensate Float Switch

: This switch

will cause a blocking error on the boiler control

and prevent the boiler from operating if the level

of condensate in the vessel becomes too high.

High condensate levels can occur as a result of a

blocked condensate drain or similar problem.

c.

Blocked Vent Switch

: A blocked vent switch is

connected to the condensate system to shut the

burner down in case of a vent blockage. The

switch will trip if the pressure in the combustion

chamber exceeds 3.5” w.c. (8.7 mbar) and will

prevent the boiler from continuing to operate with

the condensate trap emptied due to high pressure.

d.

Condensate Drain Tee

: The condensate drain tee,

included in a separate box inside the crate, drains

condensate to the trap and neutralization system

separately from the heat exchanger. This prevents

dirt and debris from the venting system from

entering the heat exchanger.

CONDENSATE TRAP & DRAIN SYSTEM

6. CONDENSATE TRAP & DRAIN SYSTEM

BLOCKED VENT

SWITCH TAPPING

Figure 6.1: Condensate Trap System