32

4. An Outdoor Sensor is provided with the Series

PFC™

boilers. It must be installed for the unit to operate

properly and to maximize the efficiency of the unit. A

warning message will be displayed on the display if

the Outdoor Sensor is not installed in the central heat

modes 1 and 2.

a. Connect the sensor to terminals #30 and #31 on

the low voltage side (right side) terminal strip.

b. The sensor should be installed in a location outside

the dwelling that is protected from harsh weather

conditions, such as driving rain and accumulated

snow, and not exposed to direct sunlight.

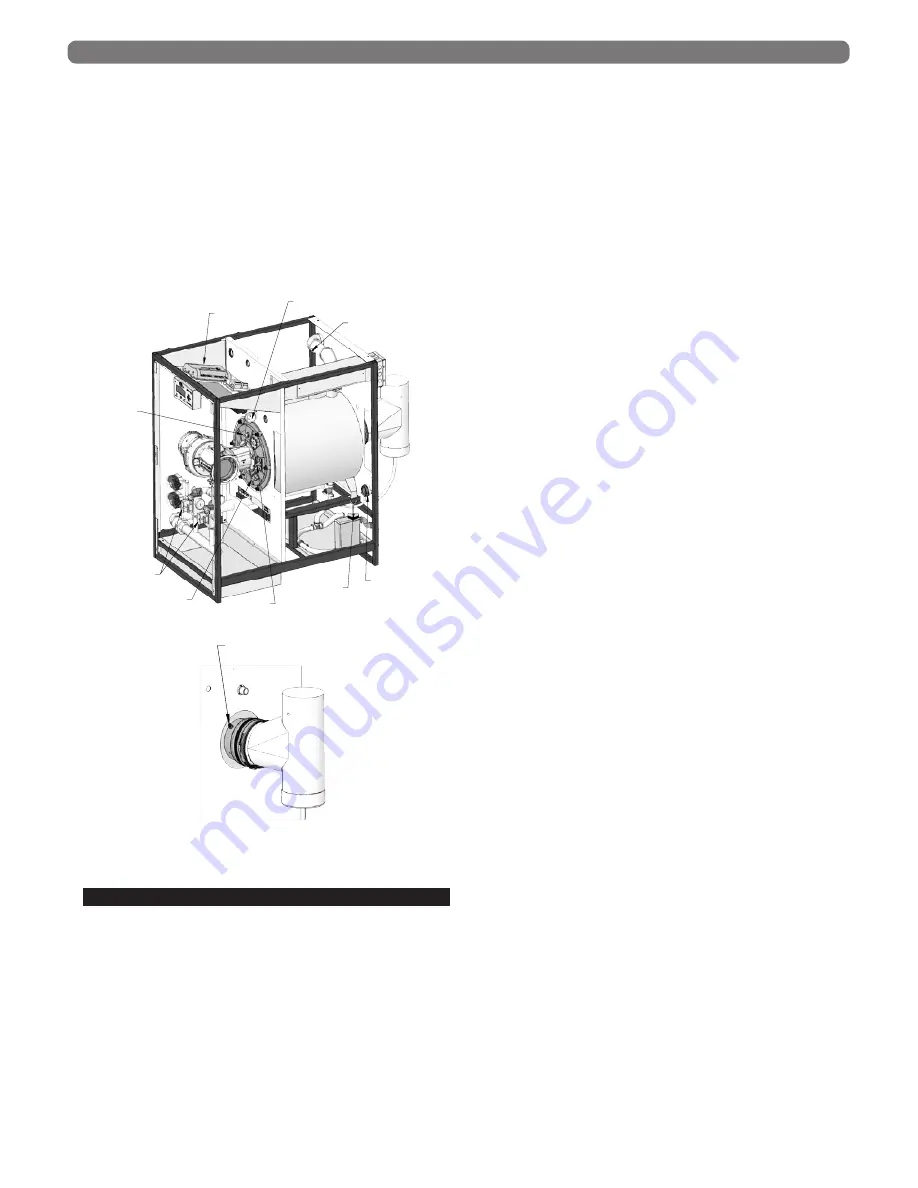

C. INTERNAL WIRING

Figure 7.4 also shows all internal wiring and sensors for

Series

PFC™

boilers.

1.

User Interface:

The user interface, 975PB Display, is

attached to the front of the electrical tray behind the

smoked lens on the jacket front panel. This interface

allows users and installer to access information on the

boiler operation and change settings on the control.

(See Section 8 for more information).

2.

Primary Ignition and Safety Control:

: The ignition

control is located on the left-hand side of the electrical

tray.

3.

Relay Module:

The relay module is located in the

center back edge of the electrical tray. This fused

module provides isolation for the pump contacts on

the main control board. The maximum rating for each

pump attached is 10 Amps. Since only two pumps

operate at any one time, this limits the incoming

power required for this module to 20 Amps. This

separate power supply is to be connected to terminals

#5 and #6.

4.

Line Voltage Terminals

: The line voltage terminals

are located on the right side of the electrical tray.

Terminals #1 through #12 are the designated line

voltage terminals. They are the left-hand column of

terminals. (A more detailed description of the terminals

can be seen in Table 7.1).

5.

Low Voltage Terminals

: The low voltage terminals

are located on the right side of the electrical tray.

Terminals #13 through #35 are the designated low

voltage terminals. They are the right-hand column

of terminals. (A more detailed description of the

terminals can be seen in Table 7.2).

6.

PC Communication Adapter (Green Plug)

: The PC

Communication Adapter (PFC7008) is detached and

located inside the electrical tray, below the terminals.

This connection allows Factory Engineers to review

control settings and view advanced diagnostic

features.

7.

Return Sensor

: The return sensor is located on the

left side, above the heat exchanger. This component

monitors the return temperature inside the boiler loop.

The thermistor is a 10 k

Ω

NTC immersion sensor

with a bayonet style connection. Only use a factory

provided Series

PFC™

return sensor.

8.

Dual Supply Sensor

: The dual supply sensor is

located on the right side, above the heat exchanger,

attached to the supply line. This component contains

2 – 10 k

Ω

NTC sensors in the sensor body. The 900

control monitors the deviation between the two sensor

readings. If the deviation is too large the control will

shut down the boiler. This ensures that the supply

temperature is accurate. The dual supply sensor acts

as a high temperature limit as well.

9.

LWCO

: The low water cutoff probe is located on the

right side, above the heat exchanger, attached to the

supply line next to the dual supply sensor. This sensor

will shut down the boiler if the water level drops

below the sensor location above the heat exchanger

to ensure the boiler does not dryfire.

10.

Flue Temperature Sensor

: The flue temperature

sensor is located on the right side of the vent of

the rear of the boiler. This sensor provides flue

temperature information to the control.

11.

Blocked Vent Pressure & Blocked Condensate Drain

Float Switches

: The blocked vent pressure and

blocked condensate drain float switches are located

on the right side, beneath the heat exchanger. The

blocked vent pressure switch is a normally closed

switch that is activated when the pressure exceeds

3.5”w.c. in the vent, indicating a vent blockage. The

blocked condensate drain float switch is activated

when there is a blockage in the condensate drainage

system. When either of these switches are activated

ELECTRICAL CONNECTIONS & INTERNAL WIRING

Figure 7.2: Safety Device Locations

FLUE SENSOR

TEMPERATURE

SWITCH

RETURN SENSOR

CONDENSATE

FLOAT SWITCH

PRIMARY SAFETY

CONTROL

IGNITOR

BLOCKED VENT

SWITCH

AIR PROVING SWITCH

FLAME SENSOR

GAS VALVES

FLUE SENSOR

TEMPERATURE

SWITCH

RETURN SENSOR

CONDENSATE

FLOAT SWITCH

PRIMARY SAFETY

CONTROL

IGNITOR

BLOCKED VENT

SWITCH

AIR PROVING SWITCH

FLAME SENSOR

GAS VALVES