35

BOILER CONTROL: INTERNAL WIRING & OPERATION

A. CONTROL OVERVIEW

The Series PFC™ boiler control is one of the primary

safety devices for the boiler. It controls:

• Ignition sequence

• Temperature Limits

• Circulators

• Gas Flow

• Setpoints

• Domestic Hot Water Priority

• Fan Speed

• LWCO

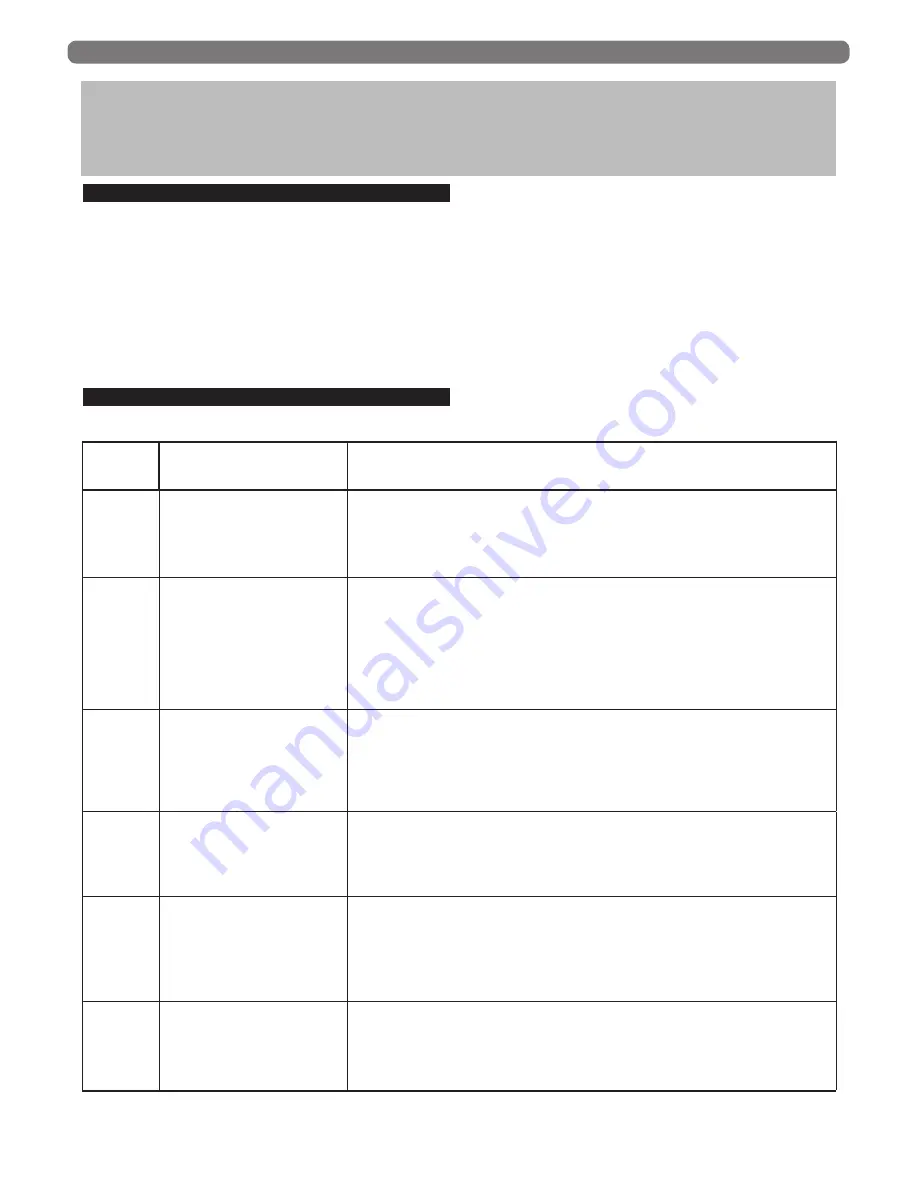

B. AVAILABLE CENTRAL HEAT MODES

Table 8.1: Series PFC™ Central Heat Modes

Central

Heating

Mode

Mode Description

Mode Operation

0

Fixed Setpoint

– Demand initiated by T/TT closure.

– User selected fixed setpoint.

– When demand is present, the boiler targets CH setpoint and

operates based on the Supply temperature hysteresis.

– Not for space heating. Used for combustion testing.

1

Outdoor reset with

Thermostat

– Demand initiated by T/TT closure.

– Setpoint is calculated based on the Outdoor temperature and CH

demand period to improve fuel usage and boiler efficiency.

– Setpoint Boost function for long CH demand periods.

– When demand is present, the boiler targets calculated CH setpoint

and operates based on the Supply temperature hysteresis.

– When the Boost Function is active and CH demand is not present,

CH setpoint decreases back to the calculated setpoint.

2

Outdoor reset with

Permanent Demand

– Demand initiated by control logic. Always present.

– Setpoint is calculated based on the Outdoor temperature to improve

fuel usage and boiler efficiency.

– Boiler targets calculated CH setpoint and operates based on the

Supply temperature hysteresis.

– When CH demand is not present, calculated setpoint decreases gradually.

3

Fixed Setpoint with

Permanent Demand

– Demand initiated by control logic. Always present.

– User selected fixed setpoint.

– Boiler maintains CH setpoint and operates based on Supply

temperature hysteresis.

– Not for space heating.

4

Analog Input Control of

Setpoint

– Demand initiated by an analog input of 1.5 Vdc or higher.

– Demand will be removed when the voltage drops below 1 Vdc.

– Boiler setpoint is controlled by an analog input signal provided by a

Building Management System or controller.

– Setpoint modulation occurs between 2 and 9 V.

– Setpoint range is 60°F (15.5°C) to 185°F (85°C).

5

Analog Input Control of

Power Output

– Demand initiated by an analog input of 1.5 Vdc or higher.

– Demand will be removed when the voltage drops below 1 Vdc.

– Boiler fan speed (power output) is controlled by an analog input

signal provided by a Building Management System (BMS) or

controller.

*While accessible via the Installer menu, CH Modes 4 and 5 are not functional with the Series PBC™ boiler.

NOTE: Hysteresis is similar to differenctial.

8. BOILER CONTROL: INTERNAL

WIRING & OPERATION