f.

Table 4.5 provides the flow rate and pressure drop

information that corresponds to various system

temperature rise values (

D

T). The pressure drop

shown is for the boiler only. If there is significant

system pressure drop in the system, this should be

included when specifying circulators.

g. Table 4.6 provides a list of recommended

circulators for boilers on a secondary loop of a

primary/secondary system which uses water as a

heating medium.

h. Special consideration must be given if a glycol

based anti-freeze solution is used as a heating

medium. Propylene glycol has a higher viscosity

than water, therefore the system pressure drop will

be higher.

10.

Indirect Water Heater:

An indirect water heater should

be piped to a dedicated zone. The

P

URE

F

IRE

boiler

provides electrical terminals for connecting a domestic

hot water (DHW) circulator. Examples of piping for

the indirect water heater are shown under subsection

“E”, System Piping of this section.

D. SYSTEM PIPING

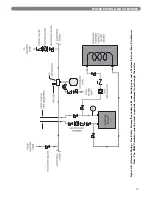

1. Figure 4.4 shows a single boiler with multiple heating

zones. In this case, the DHW zone is piped in parallel

to the heating zones on the primary loop.

2. For a single boiler with one heating zone and one

DHW zone which utilizes an indirect water heater like

the Peerless Partner, pipe the boiler as shown in

Figure 4.5. In systems like this, the DHW circulator

must be sized to provide the minimum flow rate

through the boiler.

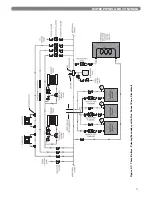

3. In Figure 4.6 an additional boiler is added and more

heating zones are shown. Notice that the two boilers

are piped in parallel on the secondary loop. This

maximizes the efficiency of the boilers since the lowest

temperature system water is returning to both boilers.

4. Figure 4.7 shows a multiple boiler system with several

different types of heat distribution units. This system

illustrates how different temperature zones can be

supplied from the same source by blending supply

and return water to the zone.

5. In Figure 4.8 zone valves are used instead of zone

circulators. Notice that the system is piped using

reverse return piping to help balance the flow through

the zones. If the zone lengths vary balancing valves

are required on each loop.

E. FREEZE PROTECTION

1. Glycol for hydronic applications is specially

formulated for heating systems. It includes inhibitors

which prevent the glycol from attacking metallic

system components. Make sure that the system fluid is

checked for correct glycol concentration and inhibitor

level.

2. Use only inhibited polypropylene glycol solutions of

up to 50% by volume. Ethylene glycol is toxic and

can chemically attack gaskets and seals used in

hydronic system.

3. The anti-freeze solution should be tested at least once

per year and as recommended by the manufacturer of

the product.

4. Anti-freeze solutions expand more than water. For

example, a 50% by volume solution expands 4.8%

with a 148°F temperature rise while water expands

about 3% for the same temperature increase.

Allowance for this expansion must be considered in

sizing expansion tanks and related components.

5. The flow rate in systems utilizing glycol solutions

should be higher than in a water system to

compensate for decreased heating capacity of the fluid.

13

WATER PIPING AND CONTROLS

Table 4.5: Boiler Pressure Drop and Flow Rates for

Various System Temperature Rise Values

D

T

(°F)

Flow Rate & Pressure Drop

PF-50

PF-80

PF-110

PF-140

GPM

FT

GPM

FT

GPM

FT

GPM

FT

40

n/a

3.20

3.2

4.40

3.1

5.65

2.3

35

2.28

2.3

3.65

4.0

5.02

3.8

6.45

2.9

30

2.66

2.9

4.26

5.1

5.86

5.0

7.53

3.7

25

3.20

3.7

5.12

7.0

7.03

6.8

9.03

5.2

20

4.00

5.4

6.39

10.4

8.79

10.0 11.29

8.0

15

5.33

8.8

8.53

17.5 11.72 17.0 15.05 14.0

10

7.99

18.5

n/a

n/a

n/a

The circulator sizing given is for primary/secondary

installations only. The system circulators must be

sized based on the flow and pressure drop

requirements of the system.

NOTICE

Table 4.6: Circulator Selection Chart

Circulator selections are based on boiler net output which

includes a 1.15 pick-up factor for piping losses.

Pump

Manufacturer

Temp

Difference

PF-50

PF-80

PF-110

PF-140

Taco

10

0014

N/A

N/A

N/A

Grundfos

UPS 26-99

N/A

N/A

N/A

Taco

15

007

0014

0014

0014

Grundfos

UPS 15-58 UPS 26-99 UPS 26-99 UPS 26-99

Taco

20

006

008

008

007

Grundfos

UPS 15-58 UPS 15-58 UPS 26-99 UPS 26-99

Taco

25

003

007

007

007

Grundfos

UPS 15-58 UPS 15-58 UPS 15-58 UPS 15-58

Taco

30

003

006

007

007

Grundfos

UPS 15-58 UPS 15-58 UPS 15-58 UPS 15-58

Taco

35

003

006

006

006

Grundfos

UPS 15-58 UPS 15-58 UPS 15-58 UPS 15-58

Taco

40

N/A

003

006

006

Grundfos

N/A

UPS 15-58 UPS 15-58 UPS 15-58

Summary of Contents for PF-110

Page 30: ...28 ELECTRICAL CONNECTIONS Figure 7 4 Internal Wiring Schematic ...

Page 56: ...54 REPAIR PARTS ...

Page 58: ...56 REPAIR PARTS ...

Page 60: ...58 APPENDIX A STATUS SCREENS APPENDIX A STATUS SCREENS ...

Page 61: ...59 APPENDIX A STATUS SCREENS ...

Page 62: ...60 APPENDIX A STATUS SCREENS ...

Page 63: ...61 APPENDIX B USER MENU APPENDIX B USER MENU ...

Page 64: ...62 APPENDIX C INSTALLER MENU APPENDIX C INSTALLER MENU ...

Page 65: ...63 APPENDIX C INSTALLER MENU ...

Page 66: ...64 APPENDIX C INSTALLER MENU ...

Page 68: ...66 NOTES ...

Page 69: ...67 NOTES ...