E. MAIN GAS VALVE - OPERATION

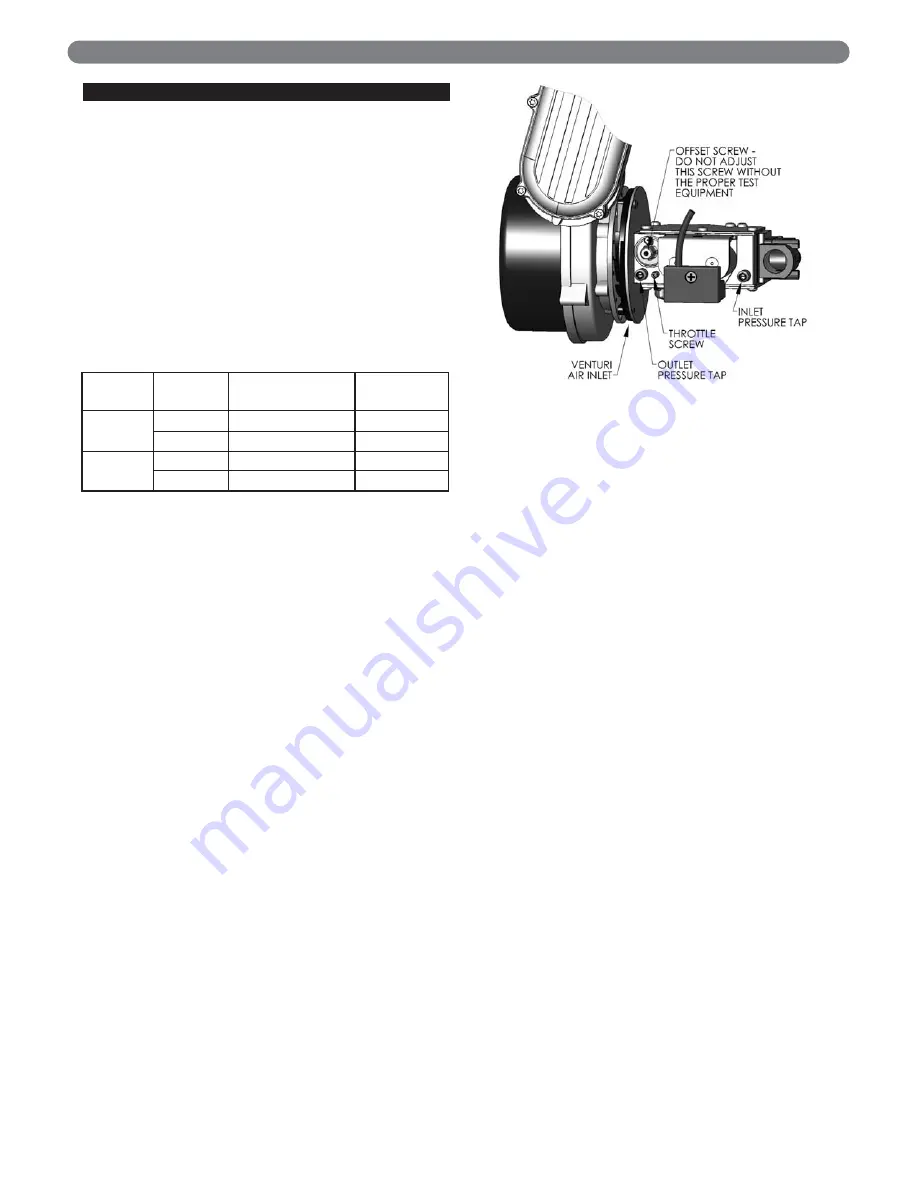

1. Figure 5.2 is an illustration of the gas valve/venturi

assembly for the

P

URE

F

IRE

Boiler.

a. Adjustments should not be made to the gas valve

without instrumentation to measure carbon

dioxide (CO

2

) and carbon monoxide (CO)

emissions in the vent pipe.

b. Turning the throttle screw clockwise will decrease

the gas flow (decreasing CO

2

) and turning it

counterclockwise will increase the gas flow rate

(increasing CO

2

). Markings adjacent to the throttle

screw show + and – indicating this operation.

c. The recommended CO

2

settings are given in Table

5.4. In no case should the boiler be allowed to

operate with CO emissions above 150 ppm.

2. Refer to Section 3, Venting and Air Intake for

information on obtaining vent samples from this

boiler.

23

FUEL PIPING

Figure 5.2: Gas Valve/Venturi

Gas Type

Firing

Rate

Vent CO

²

Vent CO

Natural

Low

8-1/2% to 9-1/2%

< 50 ppm

High

8-1/2% to 9-1/2%

< 100 ppm

LP

Low

9-1/2% to 10-1/2%

< 50 ppm

High

9-1/2% to 10-1/2%

< 100 ppm

Table 5.4: Recommended CO

2

Settings

Summary of Contents for PF-110

Page 30: ...28 ELECTRICAL CONNECTIONS Figure 7 4 Internal Wiring Schematic ...

Page 56: ...54 REPAIR PARTS ...

Page 58: ...56 REPAIR PARTS ...

Page 60: ...58 APPENDIX A STATUS SCREENS APPENDIX A STATUS SCREENS ...

Page 61: ...59 APPENDIX A STATUS SCREENS ...

Page 62: ...60 APPENDIX A STATUS SCREENS ...

Page 63: ...61 APPENDIX B USER MENU APPENDIX B USER MENU ...

Page 64: ...62 APPENDIX C INSTALLER MENU APPENDIX C INSTALLER MENU ...

Page 65: ...63 APPENDIX C INSTALLER MENU ...

Page 66: ...64 APPENDIX C INSTALLER MENU ...

Page 68: ...66 NOTES ...

Page 69: ...67 NOTES ...