G. SYSTEM TEST

The System Test feature allows the installer or service

person to make the control operate at Low Power,

Ignition Power, or Maximum Power. This is a setup and

troubleshooting tool that allows the installer or service

person to obtain combustion readings or observe

operation.

To operate the boiler under System Test, enter the

installer menu by holding down the “Menu” and “Select”

keys simultaneously for 10 seconds. Then press the “

M

”

key until the “

” indicates System Test. Press the

“Select” key to choose the menu. The default setting for

System Test is “Off”. Choose the desired setting and press

“Select” again to initiate the test.

Once the System Test is initiated, the service person may

exit the menu screen by pressing the “Menu” key until the

status screen is displayed. “System Test” will be displayed

at the top of the display screen until the operator exits the

system test mode.

H. STATUS & FAULT HISTORY

1.

General

The

P

URE

F

IRE

boiler control allows the installer to view

the status of several key parameters. In addition, it

provides details in English about the last 15 Blocking

Errors and the last 15 Lockout Faults.

The Status and Fault History can be viewed from the

Installer Menu. The Installer Menu Structure is shown

in Appendix C of this manual.

This menu can be accessed by pressing and holding

the “Menu” and “Select” keys simultaneously for 10

seconds. The “

” indicator will be indicating

“Status”. Press the “Select” Key to access this feature.

2.

Status

Current Supply Setpoint:

The first screen indicates

the current supply setpoint. In CH Mode 0, 3, and 6

this will be the setpoint selected from the User Menu.

If the boiler is operating an outdoor reset mode (CH

Mode 1 or 2) this value will be the target setpoint

temperature calculated based on the outdoor

temperature. In CH Mode 4, this value will

correspond to the 0-10 V signal input.

Fan Speeds:

By pressing the “

M

” key the operator

can view the current fan speed and the low power fan

speed. The current fan speed will be directly

comparable to the current input rate. The low power

fan speed is a factory preset software parameter that

indicates the minimum input to the boiler.

Pressing the “

M

” key again displays the ignition and

high power fan speed. Both of these are factory preset

software parameters that cannot be changed by the

installer. The ignition speed is the speed at which the

blower runs during the ignition period. The high

power fan speed corresponds to the maximum input

to the boiler.

Flame Signal/Failures:

Pressing the “

M

” key again

will display the Flame Signal/Failures Screen. The

flame signal is an indication of combustion stability of

the burner. If this value is below 1.7 µA (microampere)

the control will close the gas valve and the burner will

recycle through the ignition cycle. The flame signal

should be above 5.0 µA in normal operation.

If the control loses its flame signal 3 times during one

call for heat, it will lock out the control indicating,

“Flame Failure”. The number of flame failures in the

history of the control is displayed below the flame

signal on the menu screen.

The

P

URE

F

IRE

boiler control uses dual flame sensing to

minimize nuisance lockouts. See Section 10,

Troubleshooting, to address flame failure issues.

Ignition Attempts:

Once again, press the “

M

” key

to advance to the Ignition attempts status screen. This

screen displays the number of successful and failed

ignition attempts that have been made by the control.

If excessive ignition attempts are shown on this screen,

reference Section 10, Troubleshooting.

Boiler Run Time:

Pressing the “

M

” key again

advances the menu to show Boiler Run Time. This

indicates the number of hours that the boiler has

operated under CH or DHW demand. The values are

rounded to the nearest hour.

3.

Fault History

The following sections provide instructions on how to

access the fault history that is stored on the control.

The

P

URE

F

IRE

control stores the last 15 blocking errors

and the last 15 lockout errors and allows the installer

or service person to review the fault history of the

control.

Section 10, Troubleshooting, provides detailed

descriptions and troubleshooting approaches to the

errors reported by the control.

Last Block:

By continuing to press the “

M

” key, the

status menu displays the following screen. The last

block indicates the last blocking error (error that does

not cause a lockout). The first number indicates the

time interval in minutes since the previous error. The

#EXX represents the Error Code which can be

referenced in Section 10, Troubleshooting. The last

two lines provide an English description of the error.

Last Lock:

The next screen accessed by pressing the

“

M

” key provides information about the last lockout

error. Again the first number represents the interval

since the last lockout error. #AXX represents the Fault

Code which can be referenced in Section 10,

Troubleshooting. Again the last two lines provide an

English description of the fault.

40

BOILER CONTROL: INTERNAL WIRING & OPERATION

Be sure to set the System Test parameter back to

“Off” before leaving the installation. Otherwise,

problems with cycling or insufficient heat may occur.

NOTICE

Summary of Contents for PF-110

Page 30: ...28 ELECTRICAL CONNECTIONS Figure 7 4 Internal Wiring Schematic ...

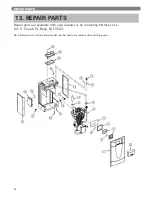

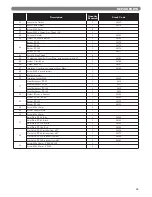

Page 56: ...54 REPAIR PARTS ...

Page 58: ...56 REPAIR PARTS ...

Page 60: ...58 APPENDIX A STATUS SCREENS APPENDIX A STATUS SCREENS ...

Page 61: ...59 APPENDIX A STATUS SCREENS ...

Page 62: ...60 APPENDIX A STATUS SCREENS ...

Page 63: ...61 APPENDIX B USER MENU APPENDIX B USER MENU ...

Page 64: ...62 APPENDIX C INSTALLER MENU APPENDIX C INSTALLER MENU ...

Page 65: ...63 APPENDIX C INSTALLER MENU ...

Page 66: ...64 APPENDIX C INSTALLER MENU ...

Page 68: ...66 NOTES ...

Page 69: ...67 NOTES ...