36

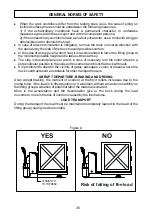

LEANING TO

TO THE HEAD

YES

NO

Risk of falling of the load

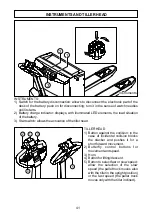

Figure A

When the work conditions differ from the testing ones (as is the case of piling on

inclined surface) there should be undertaken the following measures:

1) if the extraordinary conditions have a permanent character, to undertake

measures agreed with the surveyor and with the competent persons;

2) if the extraordinary conditions have a provisory character, use a truck with a bigger

admissible load or diminish the load.

In case of descent circulation is obligatory to move the truck in reverse direction with

the operator by the side of the truck to avoid possible overturn.

In the case of a stop (even a short one) it is recommended to lower the lifting group at

the minimum possible height and to take out the start key.

The stop in descent plane is to avoid; in case of necessity, turn the motor wheel in a

perpendicular position to the sense of movement and block the truck with nails

It is prohibited to stand in the vicinity of gates, passages, curves or places where the

truck could represent an obstacle for other transport means.

ABRUPT DEPARTURE, BRAKING AND DRIVING

At an abrupt braking, the moment of overturn at the front rollers increases due to the

inertia force: if the load is in lifted position or it was risen without a maximum stability on

the lifting group a situation of potential fall of the material is created.

More is the acceleration and the deceleration give to the truck during the load

movement, more is the risk of overturn caused by the inertia force.

LOAD TRANSPORT

During the transport the load must be maintained completely leaned to the head of the

lifting group (see figure A hereunder).

GENERAL NORMS OF SAFETY

37

Take care when the material is concentrating in one part: if there is not possible to

obtain a perfect stability of the load, it is adequate to tie up it and to move slowly,

paying maximum attention.

The overload compromises the stability and the efficiency of the device: as it is

shown in figure A of page 13 the load will be put as near as possible to the head of the

lifting group in order to distribute more equally the weight on the four wheels.

FAILURE SIGNALLING

Announce immediately to the surveyor all possible irregular utilizations, damages and

failures.

Report any occurred incident, even if there are no consequences, because in such a

way the reasons can be found and thus to eliminate them.

In the case of the stop of the truck due to electric or mechanic failures, announce the

responsible persons in order to make the necessary repairs which should be done

only by

.

authorized personal

CLOTHES

Avoid to use the truck being dressed with large or fluttering clothes

There is prohibited to come nearer to the parts in movement of the truck with long hair

not tied.

Avoid using clothes dirty of oil or fuel because these are easily to get burnt.

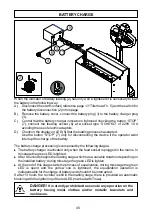

When using the truck or normal maintenance operations are executed, put on the

head a rigid cap and safe shoes; it is compulsory to use safety glasses and gloves

during the maintenance of the battery and of the oleodynamic power unit (the

electrolyte and the hydraulic oil could produce permanent damages to the sight and

skin.

NOT-AUTHORIZED MODIFICATION

There is strictly prohibited to bring not-authorized modifications to the lifter truck devices

and mechanic part without the previous authorization of the only constructing company:

the modifications could compromise the stability and the functionality of the truck and of

its safety protections implying a danger.

ECOLOGY AND POLLUTION

Concerning the utilization and the assimilation of the products used for the truck

cleaning and maintenance, there should be respected the laws in force of the respective

country; in the case of truck dismantlement, observe the anti-pollution norms in force in

the country of utilization.

RECAPITULATION: EXECUTE ALWAYS GRADUAL STARTS AND SLOW DOWNS,

MAINTAINING THE LOAD COMPLETELY PUT ON THE FORKS AT A MAXIMUM

HEIGHT OF 30 CM FROM THE SOIL; CONTROL THE STABILITY OF THE LOAD.

THE LIFTING AND LOWERING OPERATIONS SHOULD BE ALWAYS EXECUTED

WITH A STOPPED TRUCK.

PAY ALWAYS MAXIMUM ATTENTION TO YOUR OWN WORK: A SHORT MOMENT

OF INATTENTION COULD PROVOKE SEVERE INJURIES TO YOU AND TO THE

OTHERS, AS WELLAS DAMAGES TO THE TRUCK AND MATERIALS.

GENERAL NORMS OF SAFETY

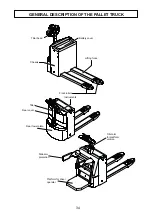

Summary of Contents for TPL 16-20-30

Page 1: ...MANUALE D USO E MANUTENZIONE TPL 16 20 30 IT UK ...

Page 26: ...26 NOTE ...

Page 27: ...27 MAINTENANCE USER MANUAL TPL 16 20 30 UK ...

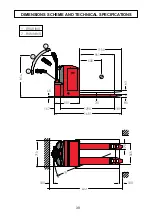

Page 33: ...33 DIMENSIONS SCHEME AND TECHNICAL SPECIFICATIONS PAPER ROLL VERSION ...

Page 54: ...54 NOTE ...

Page 55: ...55 NOTE ...

Page 57: ...GUÍA PARA EL USO Y EL MANTENIMIENTO TPL 16 20 30 ES PT ...

Page 63: ...7 ESQUEMA DE DIMENSIONES Y CARACTERÍSTICAS TÉCNICAS VERSIÓN RODILLO DE PAPEL ...

Page 84: ...28 NOTAS ...

Page 85: ...29 MANUAL DE USO E MANUTENÇÃO TPL 16 20 30 PT ...

Page 91: ...35 ESQUEMA DE DIMENSÕES E ESPECIFICAÇÕES TÉCNICAS VERSÃO ROLO DE PAPEL ...