PRGM

品番

PRGM

品番

PATTERN

工程

PATTERN

工程

STEP

ステップ

STEP

ステップ

STITCH

針数

STITCH

針数

MODE モード

MODE モード

CODE

コード

CODE

コード

CUTTER

カッター

CUTTER

カッター

COUNTカウント

COUNTカウント

DIFF. FEED

差動送り量

DIFF. FEED

差動送り量

STOP

ストップ

STOP

ストップ

E

1

1

1

ー ー

0

0

0

0

0

0

0

0

0

0

C N T

O

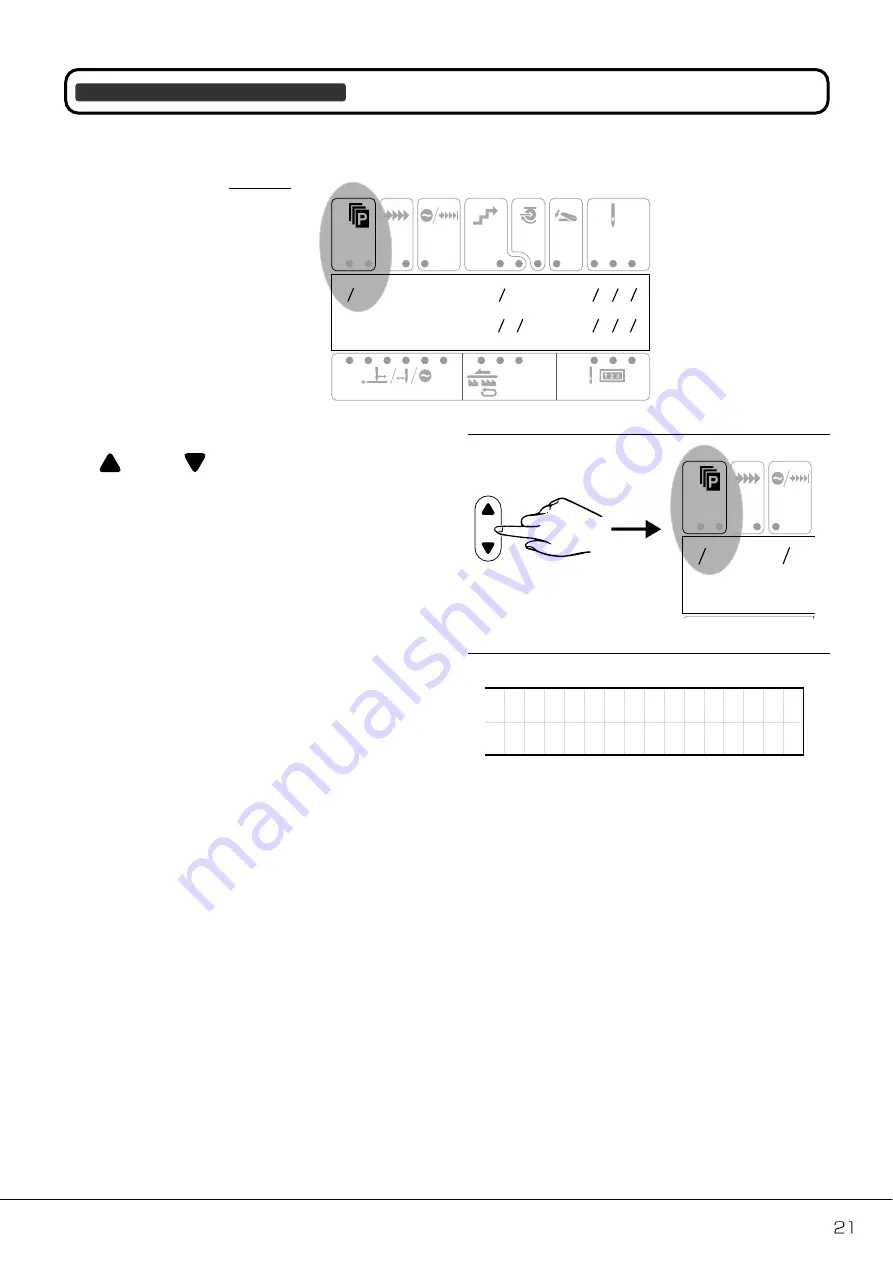

To change an item to be sewn

To select an item number ( 30 items from 1 to 30 ), press

INC.

or DEC.

key while the sewing mode is

displayed on the screen.

●

You can change an ITEM only on the Mechanic Level

(service personnel stage) with the factory-set data.

To change an ITEM on the Operator Level, select " Item

Change With M/O Level " in the function select mode

(see page 18).

Then you can change an ITEM anytime.

Change of Item number

To change and/or enter sewing data

増

増

INC.

INC.

減

減

DEC.

DEC.

PRGM

品番

PRGM

品番

PATTERN

工程

PATTERN

工程

CODE

コード

CODE

コード

1

〜

3

0

0

m

I t e

C h a n

W i t h

M

L

v e l

e

e

/ O

g

Example