Rev. 02-21 Page 51

USER MANUAL

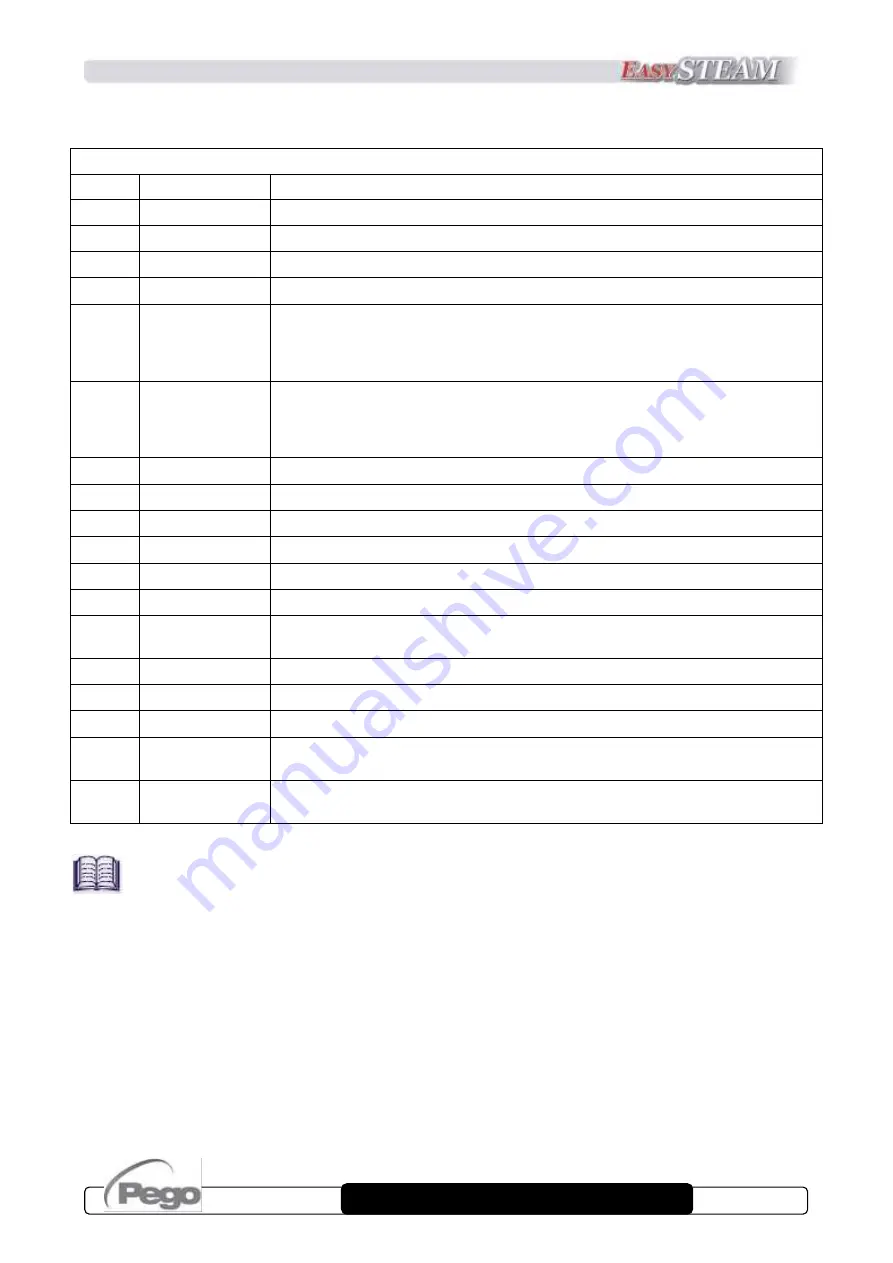

ES-MINI SERIES SPARE PARTS LIST

Ref.

Code

Description

1

UMISTHT12

Protective caps

2

UMICOCCU

ES-MINI/CCU cylinder cover

3

UMIGANCCU

ES-MINI/CCU cylinders fixing hook

4

UMIOR7

O-ring for cylinder cover

5+7+8

400UMEL01

400UMEL02

400UMEL03

Three-phase electrodes and anti-scale filter replacement kit for ES-MINI/CCU cylinders.

Monophase electrodes and anti-scale filter replacement kit for ES-MINI/CCU cylinders.

Electrodes and anti-scale filter replacement kit for low conductivity ES-MINI/CCU

cylinders.

1+2+3+

4+5+7+

8+9+13

400UMCLCCU02

400UMCLCCU01

400UMCLCCU03

Cylinder with capacity 3kg/h, electrodes, anti-scale filter and O-rings replacement kit.

Cylinder with capacity 6kg/h, electrodes, anti-scale filter and O-rings replacement kit.

Cylinder for low conductivity with capacity 6kg/h, electrodes, anti-scale filter and

O-rings replacement kit.

10

400HUMESDIS

Display NANO EasySTEAM series

11

-

ES-MINI/CCU Cylinder Bracket

12

400UMIVALV

Water load solenoid 230V 50-60 Hz ES-MINI/CCU

13

UMIOR5

O-ring for cylinder base

14

-

Base support in PP for ES-MINI/CCU

15

400UMPO25-150

Asynchronous drain pump 230V 50Hz (60Hz version available on request)

16+17+

18+20

400UMSIF07

Complete siphon replacement kit + water drain pump for ES-MINI/CCU

19

UMITUBO10-8

ES-MINI/CCU water load tube

21

-

Steel support for electronic ES-MINI/CCU

23

CON20161AP01

Power contactor, electrode power supply ES-MINI

24

400HUM2ES3M

400HUM2ES6

Master HUM2 electronic control for ES3-OEM-CCU

Master HUM2 electronic control for ES6-OEM-CCU

10+24

400KHUM2ES3M

400KHUM2ES6

Master HUM2 electronic control kit + NANO Display for ES3-OEM-CCU

Master HUM2 electronic control kit + NANO Display for ES6-OEM-CCU

The spare parts must be requested from own dealer.