AIR10-1420A Operation Manual

Project maintenance process

41

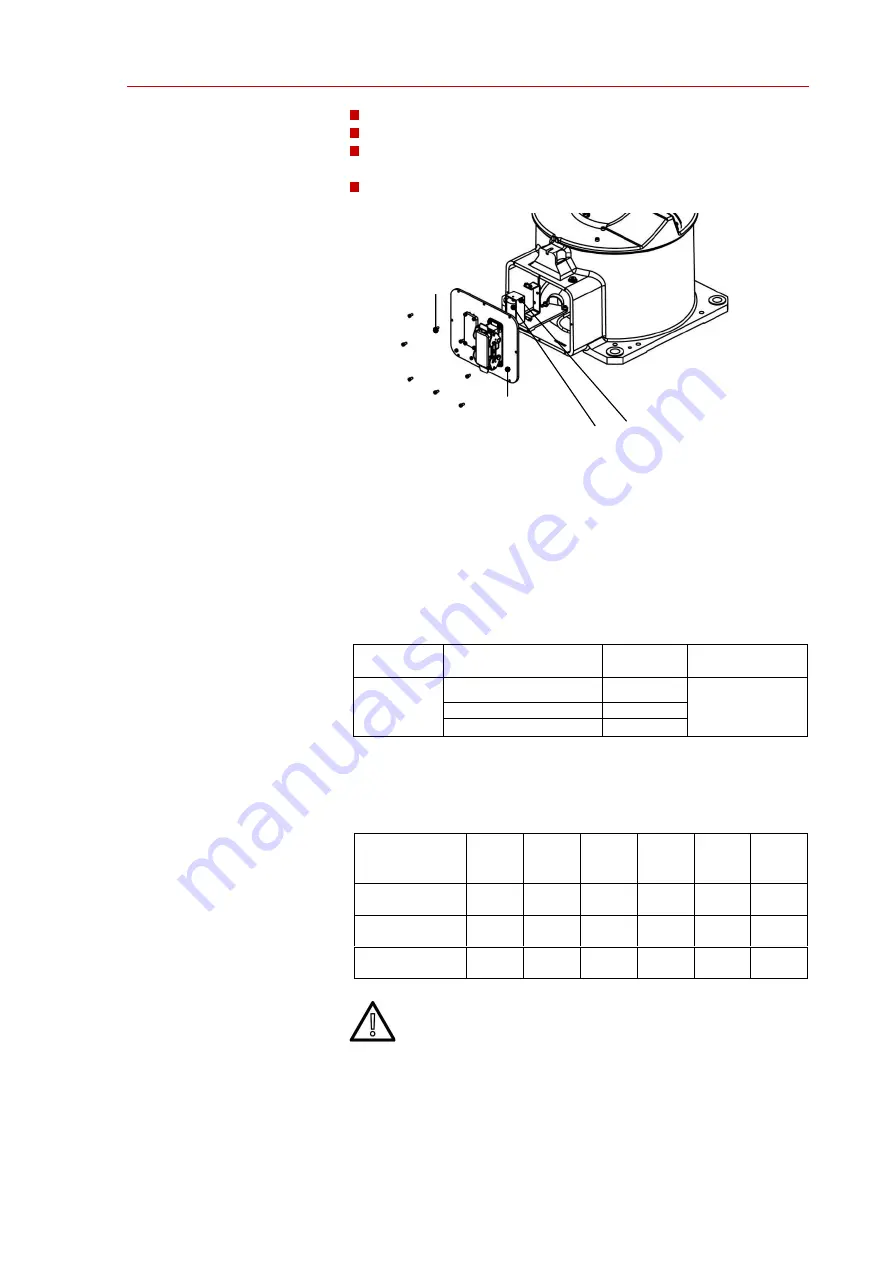

Reconnect the battery cable.

Install the battery box.

Install the electrical installation plate, and apply sealant on the joint

surface of the electrical installation plate and the base casting

After all safety conditions are met, calibrate and test the operator

Fig. 13-5 removing the electrical installation panel of the operator

13.4

changing grease

The internal grease shall be replaced every 11520 hours or 3 years (whichever

is shorter) from the operation of the machine's j1axis to J6 axis reducer.

Refer to Table 13-1 for model and quantity of lubricating grease:

Table 13-1 type and quantity of lubricating grease of the operator

Model of

operator

Replacement of grease

Grease

content

Grease model

AIR10-1420A

J1axis reducer

290g

VIGOGREASE RE0

J2 shaft reducer

250g

J3 shaft reducer

145g

When changing the lubricating grease, please refer to Table 13-2 for the

operator attitude:

Table 13-2 Operator's attitude of changing lubricating grease

Replacement of

grease

J1

J2

J3

J4

J5

J6

J1 axis reducer

180

°

0

°

90

°

Arbitrar

y angle

Arbitrar

y angle

Arbitrar

y angle

J2 axis reducer

0

°

0

°

90

°

Arbitrar

y angle

Arbitrar

y angle

Arbitrar

y angle

J3 axis reducer

0

°

45

°

-45

°

Arbitrar

y angle

Arbitrar

y angle

Arbitrar

y angle

Warning

The oil temperature of reducer may be higher than 90 °

and it shall be replaced

after cooling

Wear gloves to prevent allergic reactions

Screw M4X8

Battery

Electrical installation board

Battery case