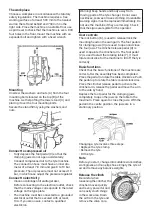

If the locking lever does not lock the vertical arm

properly or if the mounting head cannot be lifted

at least 2 mm above the rim, which is necessary

for proper operation, loosen the nut and adjust the

allen screw according to the figure.

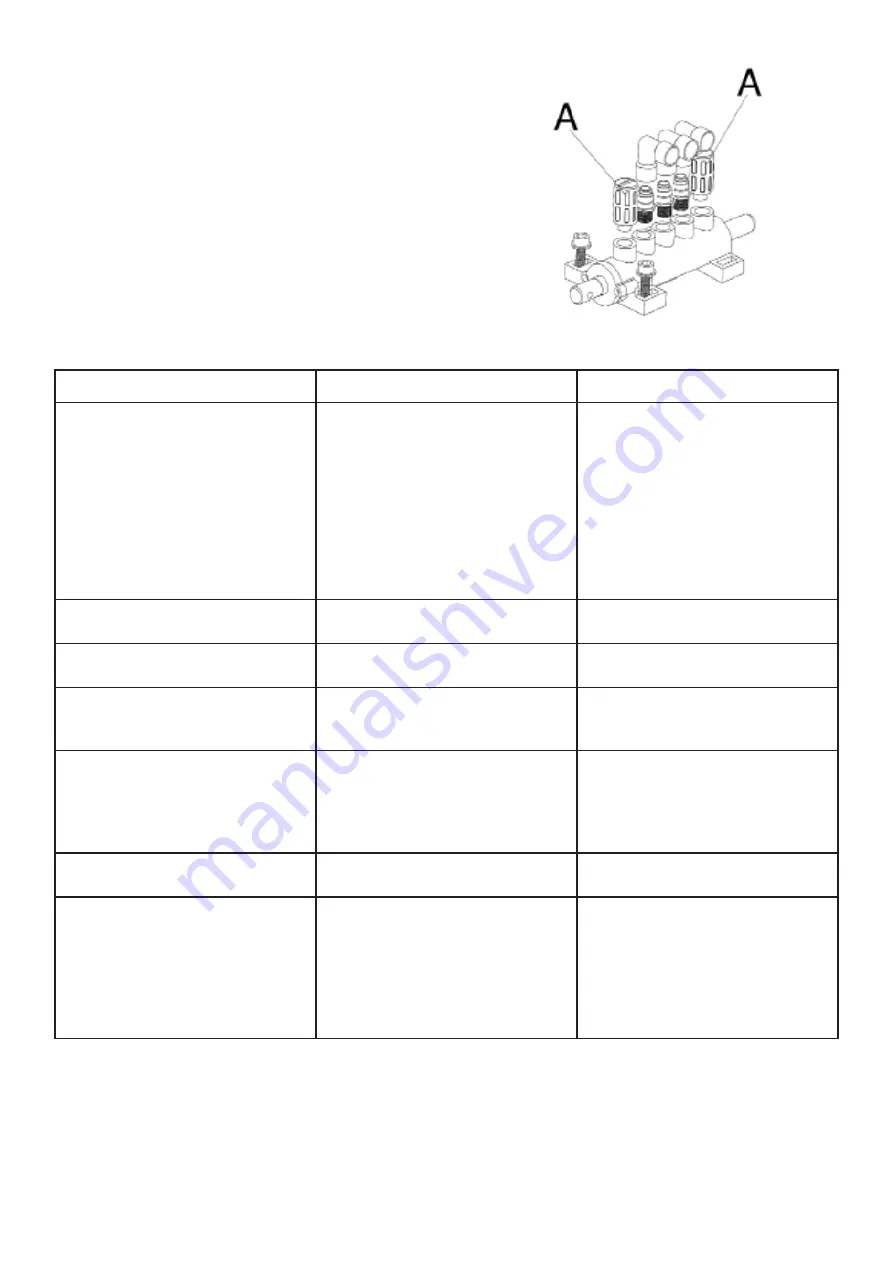

To maintain the reliability of the clincher and

clamping jaws, the mufflers on the valve should be

blown clean, remove the sheet metal cover on the

left side of the machine part by unscrewing the two

allen screws (5 mm). Remove the mufflers from the

valve. Clean with compressed air (purge gun) or

replace, if required.

Issue

Reason

Solution

The table does not rotate

The plug is not connected / there

is no power in the mains

Engine problem

The foot pedal (Z) does not work

The belt is poorly tensioned or

broken

Connect the plug / switch on the

power

Check and repair the rotating

table

Adjust or replace the belt

The table locks during assembly/

disassembly of the tyre

Poorly tensioned belt

Tighten the belt

The clamping jaws open/close

slowly

The compressed air muffler is

clogged with dirt

Clean or replace the compressed

air muffler

The table does not lock the rim

properly

Worn clamping jaws

Defective piston

Replace the clamping jaws

Replace the gasket

The mounting head touches the

rim when mounting / removing

the tyre

Spindle lock incorrectly adjusted

or defective

Loosen the screw on the spindle

lock

Adjust or replace the spindle lock

Tighten the screw

The foot pedal (V) and (U) are

locked in the wrong position

The return spring of the pedal is

broken

Replace the return spring

Difficult to activate the clincher

The compressed air muffler is

clogged

The valve stem’s O-ring is broken

The piston gasket or O-ring is

broken

Clean or replace the compressed

air muffler

Replace the O-ring

Replace the gasket or O-ring

Summary of Contents for 32836

Page 1: ...Tyre changer U 2011 D ckmaskin U 2011 Item No 32836...

Page 8: ...Varningsskyltarna...

Page 9: ......

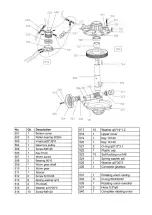

Page 16: ...Exploded view...

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

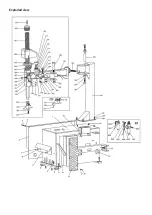

Page 25: ...Electrical circuit diagram...

Page 26: ...Pneumatic diagram...

Page 28: ......

Page 29: ......