Use the container within the pressure and tempera-

ture limits indicated on the nameplate.

• The vessel must not be altered, either by welding,

drilling or other mechanical processing methods.

• The service life of the machine depends on how

carefully perform the maintenance procedures.

• Before carrying out any operation, set the pressure

switch to the "OFF" position, pull out the plug and

empty the air tank completely.

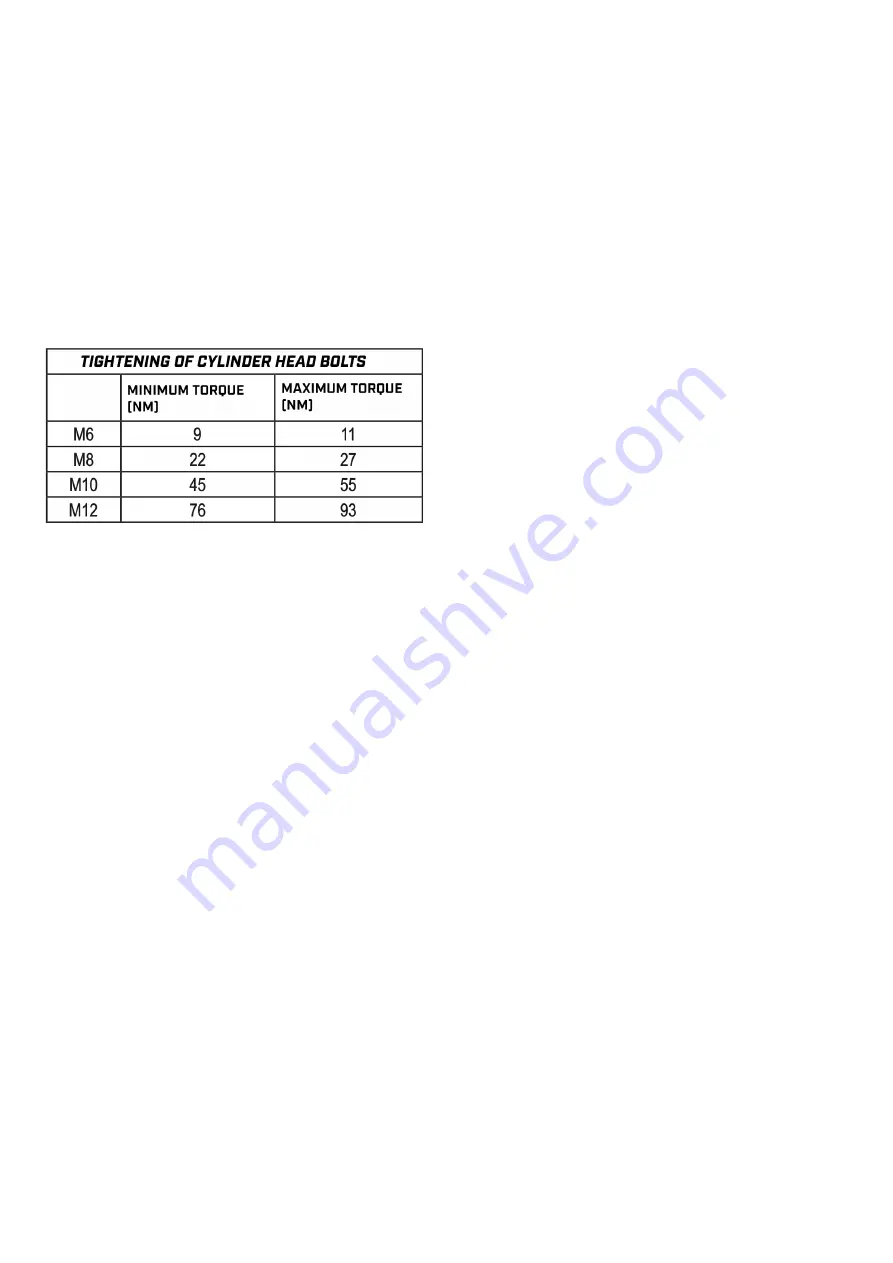

• Check that all screws are tightened (especially the

bolts on the compressor cylinder head cover) before

starting the compressor for the first time. Check at

regular intervals.

• Clean the intake salt regularly depending on the

ambient conditions, but at least every 100 hours of

operation. Replace the filter if necessary

• Change the oil after the first 10 operating hours

and then every 120 operating hours. Check the level

regularly.

• Use mineral oil SAE 30 (In cold climates, SAE 20

is recommended), do not mix different grades. If

the oil color changes (white = water in the oil, dark

= overheated), it is recommended to change the oil

immediately.

• Tighten the filler plug firmly and check that there

is no leakage during operation. Check the oil level

once a week to ensure that the lubrication is done

correctly.

• Both the consumed oil and the condensate must

be disposed of in accordance with current environ-

mental protection regulations and laws.

Information on disposal and recycling of this

product

Information on disposal

The compressor must not be disposed of with

normal household waste. Contact your local autho-

rity for further information on waste management

that consists of or contains electrical or electronic

components.