the result by lowering the protective hood and

pressing the START key, the wheel spins, when it

stops, both side displays should show zero. The

balancing is complete.

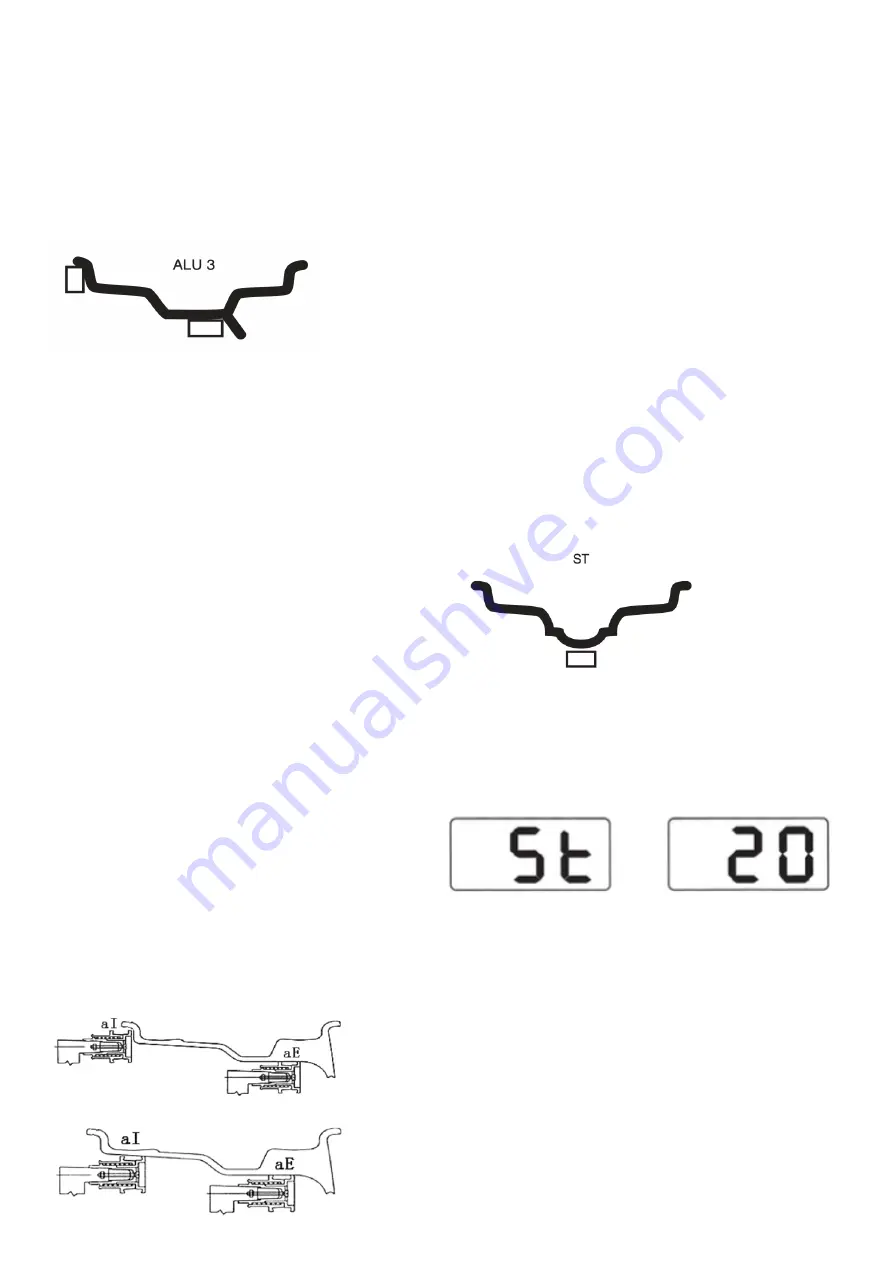

Balancing process and input method for ALU-

3 mode.

Press the ALU button so that the ALU-3 indicator

lights up.

Enter rim data, close the protective hood and press

the START button, the wheel rotates. When it has

stopped, the correction weights of the wheel are

shown on the displays, slowly rotate the wheel,

when all the diodes in the indicator for the inside

balance weight position light up, clamp the

corresponding correction weight at 12 o’clock on

the rim edge. Slowly rotate the wheel again, when

all the diodes in the outside balance weight

position indicator light up, paste the corresponding

correction weight at 12 o’clock on the rim. Check

the result by lowering the protective hood and

pressing the START key, the wheel spins, when it

stops, both side displays should show zero. The

balancing is complete.

Balancing process and input method for

ALU-S mode.

These three variants of ALU mode are not

suitable for all types of tires, and some tires cannot

be balanced with a good result. In this situation, the

ALU-S mode can be used. The data entry method

is as follows: Press the ALU button, until the ALU-S

LED lights up, pull out the dipstick to the inside of

the rim (aI) (the position you select there, paste the

balance weight on the inside). Press [a-] or [a +] to

enter the value ”aI”. When the dipstick has

registered the aI value, pull out the dipstick to (aE)

(the position you select there is to paste the

external balance weight) aE value, press [b-] or [b

+] to enter the value “aE”. Using the wheel width

gauge, to measure the diameter (dI) on the inside

(AI), press [d-] or [d +] to enter the value “di”.

Use the wheel width gauge to measure the

diameter (dE) on the outside (aE) of the rim, press

and hold the [FINE] key and press the [d-] or [d +]

key to enter the “dE” value. Rim data is entered,

close the protective hood and press the START

button, the wheel rotates. After stopping, the

displays show imbalance between the two sides.

slowly rotate the wheel, when all the diodes in the

inside balance weight indicator light are on, paste

the corresponding correction weight at 12 o’clock

on the inside of the rim. Slowly rotate the wheel

again, when all the diodes in the outside balance

weight position indicator light up, paste the

corresponding correction weight at 12 o’clock on

the outside of the rim. Check the result by lowering

the protective hood and pressing the START key,

the wheel spins, when it stops, both side displays

should show zero. The balancing is complete.

Static balance (ST)

ST position is only suitable for rims, where the

balance weight can be attached centered on the

rim, such as a motorcycle rim.

In normal mode, measure the diameter ”d” on the

rim, then press [d +] or [d-] to enter the value ”d”.

(”A” and ”b” can be random value). Press [F] to

enter ST mode. Close the protective hood and

press the START button, the wheel rotates.

After stopping, the left display shows ST, the right

display shows the imbalance weight slowly rotate

the wheel, when all the diodes in the indicators for

inside and outside balance weight position light up,

the adhesive correction weight at 12 o’clock

centered on the rim. Check the result by lowering

the protective hood and pressing the START key,

the wheel spins, when it stops the display should

show zero. The balancing is complete.

Conversion

Sometimes you can balance a tire and afterwards

find out that the rim data is not correct. Then you

do not need to perform the balancing again, just

press C (conversion) and enter new data.

Summary of Contents for 506799

Page 1: ...Automatic wheel balancer U 800 D ckbalanseringsmaskin U 800 Item No 506799...

Page 12: ...Reservdelslista...

Page 13: ......

Page 14: ......

Page 16: ...Funktionsdiagram...

Page 17: ...Blockschema...

Page 18: ......

Page 29: ...Spare parts list...

Page 30: ......

Page 31: ......

Page 33: ...Function diagram...

Page 34: ......

Page 35: ......