The system then recalculates after the new ones

the conditions.

.

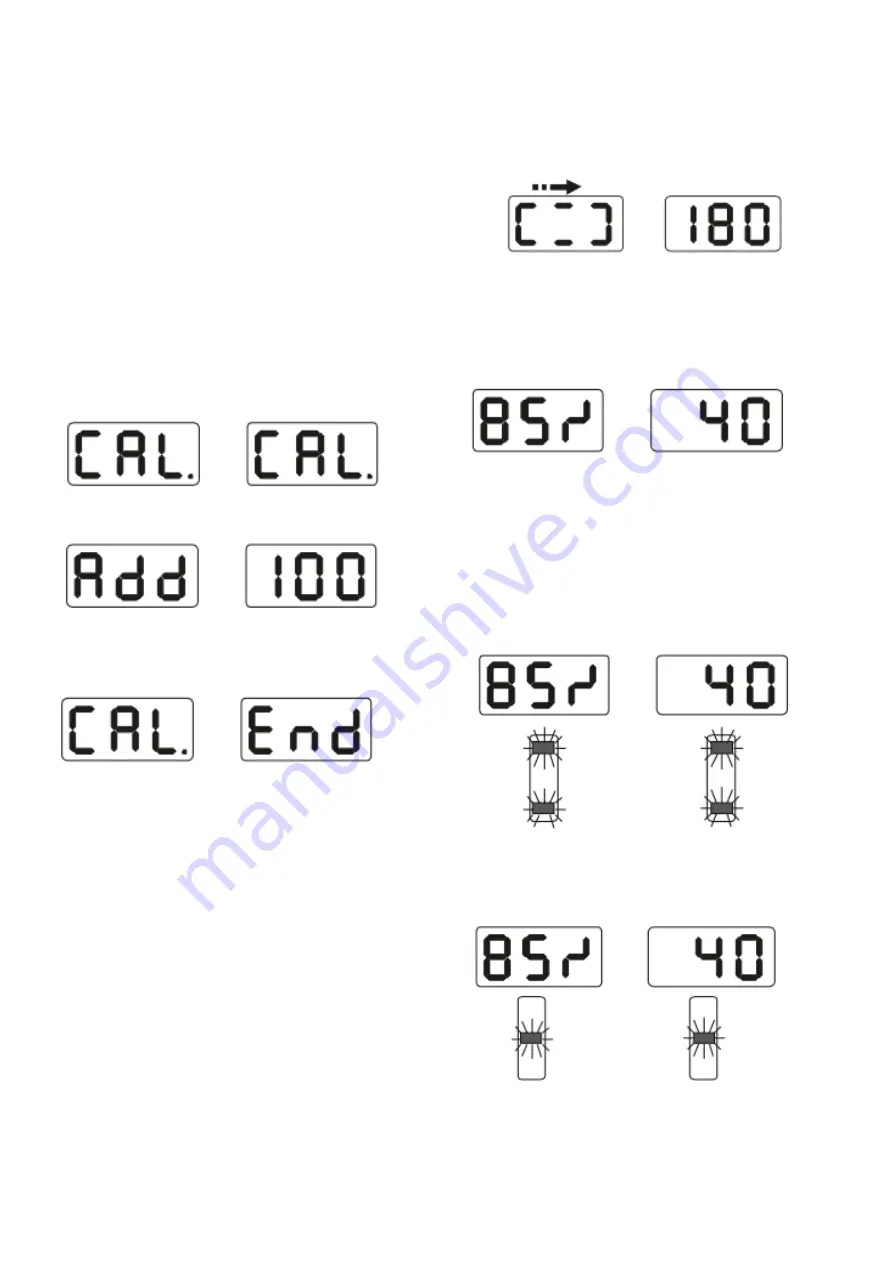

Self-calibration

The machine is calibrated from the factory - there

is a risk that the calibration has changed during

transport. Therefore, it may be a good idea to

calibrate the machine before using it. (Test first

and run the machine - it is very rare that the

settings have changed).

Switch on the machine and program the rim data

according to point 7, use a mid-range tire (14 ”or

15”). You can always press STOP or C to cancel.

Press F and the C button. The user is prompted to

perform the necessary actions during the

calibration.

Close the hood.

Open the hood, the user is instructed to mount a

balance weight of 100 g on the outside, then close

the hood.

Close the hood, the wheel rotates and when it

stops you can read in the display ”cal end”. Press

C.

Remove the calibration wheel and test with other

wheels so that everything works.

When calibrating, remember to be careful with

settings of rim data and that the calibration weight

is correct, otherwise the calibration will be

incorrect and subsequent balances will not keep

the promised precision.

Do not mount the 100 gram weight before

calibration - then the computer thinks it is not

there and all calibration is incorrect - it will be

wrong to cancel and enter the calibration program

from step one.

Be careful about the enclosed calibration weight,

for a good result it is important that the correct

weight is used in a possible calibration.

Optimization of imbalance

If the wheel imbalance exceeds 30 g, the system

will display OPT. Do the following to optimize the

tire’s position on the rim.

Press the OPT button.

Make a mark on the rim and on the tire with a

chalk, then loosen the tire with a tire machine to

move it 180 degrees on the rim. Refit the tire on the

balancing machine and press START.

The display shows the optimization in percent, if

the optimized value is 40 g and the optimization

is 85%, it means that the static value that remains

after the action is only 6 g (15% x40g = 6g).

Rotate the wheel slowly by hand until the outer

indicators light up, make a mark with the chalk on

the rim (12 o’clock).

Rotate the wheel slowly until the center indicators

illuminate, making a mark with the chalk on the tire

(12 o’clock).

Then loosen the tire with a tire machine to adjust

the marking on the tire and the rim in the middle of

each other. You have now optimized the position of

the tire on the rim.

Summary of Contents for 506799

Page 1: ...Automatic wheel balancer U 800 D ckbalanseringsmaskin U 800 Item No 506799...

Page 12: ...Reservdelslista...

Page 13: ......

Page 14: ......

Page 16: ...Funktionsdiagram...

Page 17: ...Blockschema...

Page 18: ......

Page 29: ...Spare parts list...

Page 30: ......

Page 31: ......

Page 33: ...Function diagram...

Page 34: ......

Page 35: ......