Press and hold [FINE], then press the [a +] and [a-]

keys, the unit of weight is converted to grams.

Press the [FINE] + [a +] + [a-] keys again, the unit of

weight is converted to grams.

Repeat to convert the weight unit between grams

and oz.

Other features

Minimum value display settings

Select the lowest display value, if the wheel’s

imbalance value is less than the setting value, the

result is displayed with 0. Press the FINE key, the

actual imbalance value can be displayed.

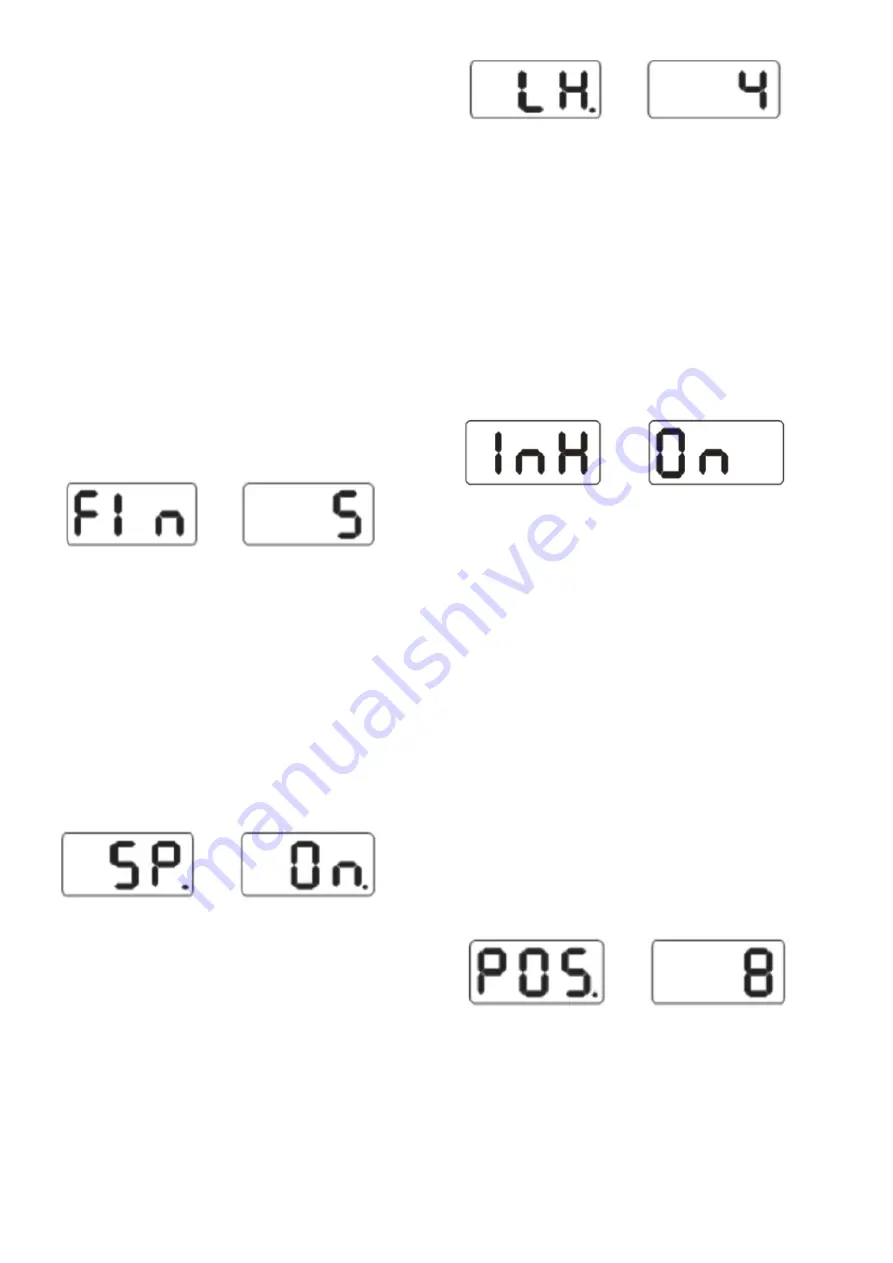

Press the [FINE] + [MODE] keys. See image below

which means that if the imbalance value is less

than 5 grams, the result is displayed 0, press [b-] or

[b +] to set the minimum display value: 5.10 OR15.

Press the [a +] button to save the current setting

and enter the next step.

Function settings key

This function can activate or deactivate key tones.

When you turn on this function, each time you

press the button, a ”di” tone will sound. When you

turn off this function, you press the button and

there is no tone. Press the [a +] button to enter,

when the right side shows ON, it means that the

function is switched on. When the display shows

OFF, it means that the function has been switched

off. Press the [b-] or [b +] button to toggle between

”ON” and ”OFF”. Press the [a +] button to save the

current setting and enter the next step.

Display screen brightness settings

This function is to set the screen brightness

according to working environment and user

requirements Press the [a +] button to enter, show

image 11-3, right side shows brightness level.

Completely 8 levels. Level 1 means the darkest

display. Level 8 is the brightest screen. The default

level is 4. Press the [b-] or [b +] button to change

levels. Press the [a +] button to save the current

setting and enter the next step.

INCH and MM conversion operation

Most rims have unit INCH sizes. If the device is

MM, the system device can be set to MM. If the

value is decimal, the current unit is INCH. If the

value has no decimal, the current unit is MM. This

setting is not retained when the machine is turned

off.

The system setting unit is INCH. Press the [a +]

button to enter, the right side shows ON, means

the unit is INCH, shows OFF, means the unit is MM.

Press the [b-] or [b +] button to toggle “ON” and

“OFF”. Press the [a +] button to save the current

setting and exit.

Machine self-test function

This function is to check if all input signals are

normal and supports problem analysis.

Check the LED lamp and control lamp

Press the [SET] + [MODE] buttons, the indicator

light and the LEDs. This function can check if LEDs

or indicator lights are damaged. Checking ends and

display. Enter the position sensor signal control.

Press the [SET] button to exit.

Position sensor signal control

This function can check if the position sensor, the

main shaft, the main board circuit are faulty. The

main shaft rotates slowly and the value changes as

shown on the right side, see picture below. Rotate

clockwise, the value increases; Rotate

counterclockwise, the value decreases. Normally

the value changes between 0-63. Press the [a +]

button to enter the test sensor signal control. Press

the [SET] button to exit.

Press the sensor signal control

This function can check if the pressure sensor,

the motherboard signal circuit and the power card

are faulty. Press the [a +] button to enter (Fig12-2).

Then press lightly on the main shaft. Normally, the

values shown on the display should be changed.

Press the [a +] or [SET] button to exit.

Summary of Contents for 498192

Page 1: ...Tyre changer balancer 2 in 1 D ckmaskin balanserare 2 i 1 Item No 498192...

Page 11: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 33: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......