A. Remove plastic wrap and cardboard packaging from door. Do not remove plastic

shipping spacers. The shipping spacers will help keep the door square during installation.

DO NOT unlock or open the door until it is fully fastened.

Note: If screens, grilles or hardware are removed from the door at this time, label them

and store them in a protected area.

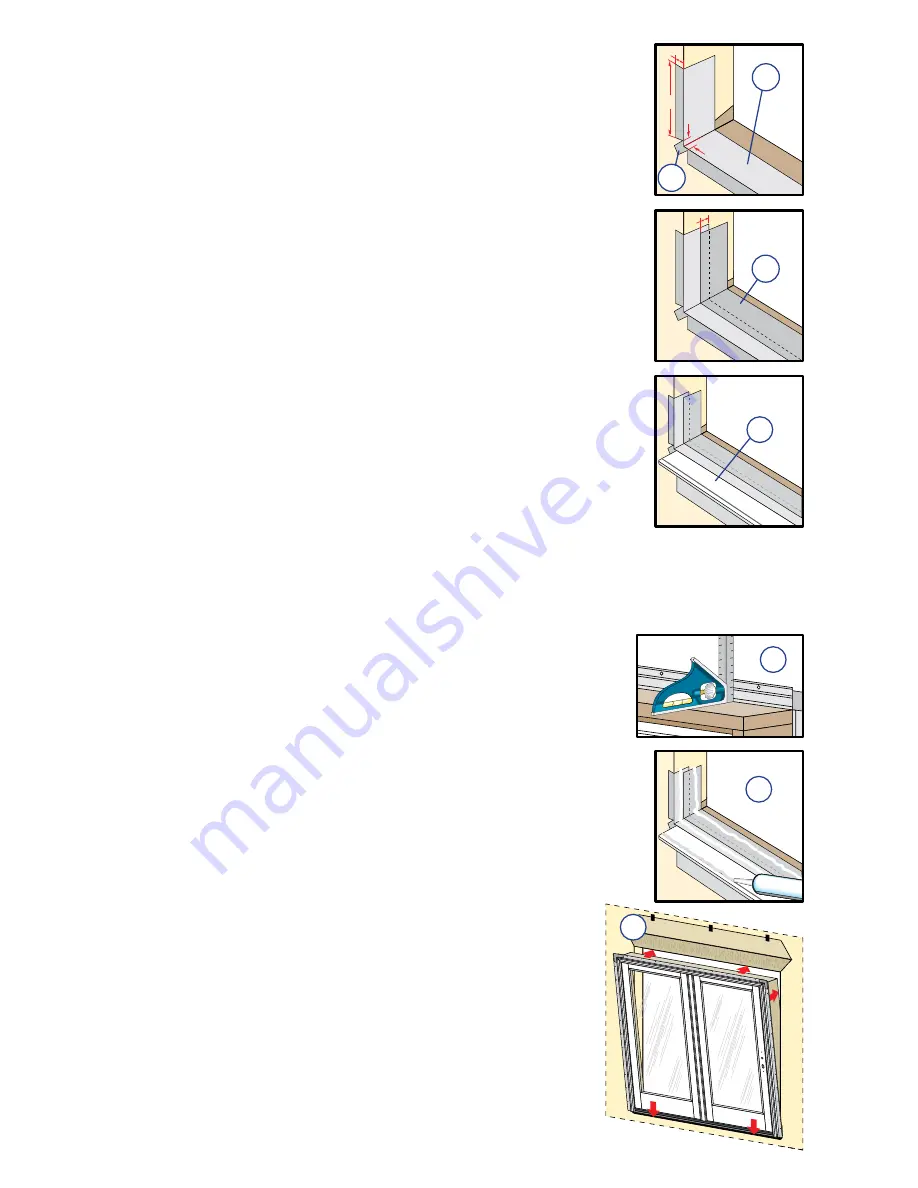

B. Fold out installation fin to 90°. Be careful not to remove or tear

the fin corners.

Note: If the fin is not at 90°, the door will not line up correctly

on the interior.

C. Place three 3/8" beads of sealant.

The first bead should be

approximately 3/4" from the exterior of the rough opening, the

second bead should be placed so it is under the wood interior

threshold of the door. Placement will vary depending on wall

thickness and door type. Place a third bead of sealant in the groove of

the sill support or 1/4" from the exterior edge of the wood blocking.

TWO OR MORE PEOPLE WILL BE REQUIRED

FOR THE FOLLOWING STEPS.

E. Apply sill flashing tape #1.

Cut a piece of flashing tape 12" longer

than the opening width. Apply at the bottom of the opening as shown

(1E) so it overhangs 1" to the exterior.

Note: The tape is cut 12" longer than the width so that it will

extend 6" up each side of the opening.

2

SETTING AND FASTENING THE DOOR

F. Tab the sill flashing tape and fold.

Cut 1" wide tabs at each corner

(1/2" from each side of corner) (1F). Fold tape to the exterior and

press firmly to adhere it to the water resistive barrier.

G.

Apply sill flashing tape #2.

Cut a piece of flashing tape 12" longer

than the opening width. Apply at the bottom, overlapping tape #1

by at least 1". Do not allow the tape to extend past the interior face

of the framing (1G).

H.

Attach the aluminum sill support or wood blocking

to the exterior

of the box plate to support the edge of the door sill. Place the sill

support flush with the subfloor.

D. Insert the door from the exterior of the building. DO NOT

slide the bottom of the door into the opening. Sliding will

damage the sealant lines. Place the bottom of the door at the

bottom of the opening, then tilt the top into position. Center

the door between the sides of the opening to allow clearance for

shimming, and insert one roofing nail in the first hole from the

corner on each end of the top nailing fin. These are used to hold

the door in place while shimming it plumb and square.

1F

1"

1/2"

1/2"

6"

1E

1"

1G

1H

2B

2C

Exterior

2D