YOU WILL NEED TO SUPPLY:

Ř

Cedar or Impervious shims/spacers (12 to 20)

Ř

2" galvanized roofing nails (1/4 lb.)

Ř

Closed cell foam backer rod/sealant backer

(24 to 32 ft.)

Ř

Pella® SmartFlash™ foil backed butyl window

and door flashing tape or equivalent

Ř

Pella Window and Door Installation Sealant or

equivalent high quality, multi-purpose sealant

(2 to 3 tubes per door)

Ř

Low expansion, low pressure polyurethane

insulating window and door foam sealant

- DO NOT use high pressure or latex foams

Ř

Pella aluminum sill support or 2 x 4 wood blocking

Ř

Interior trim and/or jamb extensions (15 to 40 ft.)

FOR MULLION APPLICATIONS:

Ř

I bar joining connector

Ř

Pella silicone foam tape

Ř

Mullion end plug (2)

Ř

Field applied fins (4 pcs. per unit)

Ř

Head drip fin (Vertical Mullion applications only)

TOOLS REQUIRED:

Ř

Tape measure

Ř

Level

Ř

Square

Ř

Hammer

Ř

Stapler

Ř

Hacksaw

Ř

Sealant gun

Ř

Scissors or Utility knife

Ř

Screwdrivers

Ř

(#2 Phillips with 8" shaft and small

flat blade)

Ř

Rubber mallet

Ř

Drill

Installation will require two or more

persons for safety reasons.

4&"-"/5

4&"-"/5

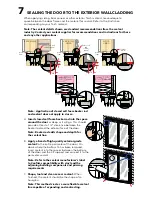

A.

Confirm the opening is plumb and level.

Ensure the bottom of the rough opening does

not slope towards the interior.

Note: It is critical the bottom is level.

*OUFSJPS

"

*OUFSJPS

#

4th cut:

Make a 6" cut up from

each top corner at a 45

o

angle to allow the water

resistive barrier to be lapped

over the fin at the head of

the door.

1st cut

2nd cut

3rd cut

Water Resistive Barrier

1C

B.

Confirm the door will fit the opening.

Measure all

four sides of the opening to make sure it is 1/2" larger

than the door in width and height. Measure the width

at the top, bottom and center. Measure the height at

the far left side, the far right side and in the center.

Note: Solid wood blocking of 1-1/2" or more is

required around the perimeter of the opening.

Fix any problems with the rough opening before

proceeding.

C.

Cut the water resistive barrier.

1

ROUGH OPENING PREPARATION

1A

1B

1C