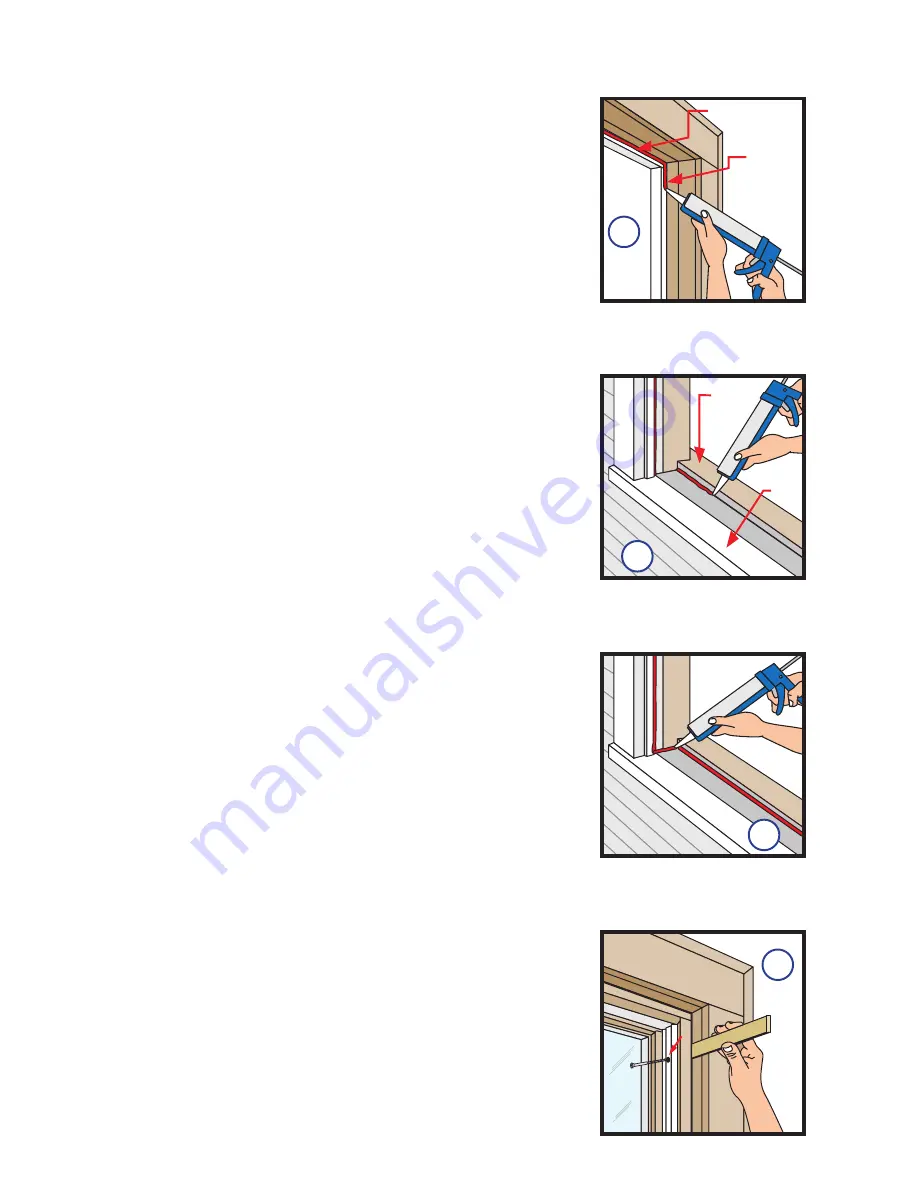

3C

A.

Apply a 3/8" continuous bead of sealant

to the interior

face of the existing blind stops at the head and both jambs.

B.

Place a bead of sealant

where the existing stool meets the

existing frame sill and jambs.

C.

Place a bead of sealant

where the jamb and sill meet.

D.

Insert the window into the opening.

Set the bottom of the

window in first and tilt the top into place. Make sure the

window is centered in the opening and is pressed firmly

against the exterior blind stops.

E.

Place a shim at each of the top corners

in line with the pre-

punched holes, and partially insert 2-1/2" screws (provided).

This will hold the window in place while shimming it plumb

and square. Trim shims back so they recessed back 1/4” -

1/2” from the interior face of the window frame.

3

SEALING AND FASTENING THE WINDOW

3A

Jamb

blind

stop

Head blind

stop

Sill

Stool

3B

3E