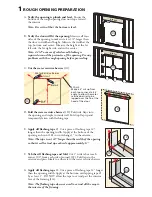

Note: Pre-drilling the additional holes in the fin at the interlocker

will make installation easier and will help prevent damage to the

fin. Use a 3/16" drill bit to pre-drill the holes.

&YUFSJPS

Î

C.

Fasten the door to opening

:

3C

High Performance

Screw Placement

2" 2" 2" 2"

A.

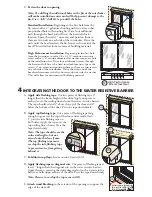

Apply side flashing tape.

Cut two pieces of flashing tape 4"

longer than the frame height of the door. Apply one piece to

each side over the nailing fin and onto the water resistive barrier.

The tape should extend 2" above the top of the door and 2"

below the bottom of the door. Press the tape down firmly.

&YUFSJPS

{

B.

Apply top flashing tape.

Cut a piece of flashing tape long

enough to go across the top of the door and extend at least

1" past the side flashing tape on

both sides. Apply the tape over the

top nailing fin as shown. Press the

tape down firmly.

Note: The tape should cover the

entire nailing fin, but not

extend onto the door frame.

The top flashing tape must

overlap the side flashing tape

to prevent water from getting

behind it.

&YUFSJPS

{

&YUFSJPS

{

{

4PMJEXPPECMPDLJOH

UIFFOUJSFMFOHUIPG

UIFTJMMNFNCFS

{

C.

Fold down top flap

of water resistive barrier (4C).

D.

Apply flashing tape to diagonal cuts.

Cut pieces of flashing tape at

least 1" longer than the diagonal cuts in the water resistive barrier.

Apply the tape, covering the entire diagonal cut in the water resistive

barrier at both upper corners of the door. Press the tape down firmly.

Note: Be sure to overlap the top corners (4D).

E.

Attach wood blocking

to the exterior of the opening to support the

edge of the door sill.

4

INTEGRATING THE DOOR TO THE WATER RESISTIVE BARRIER

Standard

Installation:

Beginning in the first hole from the

fin corner, drive 2" galvanized roofing nails into every other

pre-punched hole in the nailing fin. Drive four additional

nails through the head and sill fin at the fixed interlock

location. Space the nails 2" on center and position them so

there are two nails on each side of the interlocker. Drive the

nails until the head contacts the fin, however do not sink the

head. This will allow for movement of building material.

High Performance Installation

: Beginning in the first hole

from the fin corner, insert a #8 x 1-1/2" corrosion resistant

screw with a 3/4" outside diameter flat washer into every hole

of the installation fin. Drive four additional screws through

the head and sill fin at the fixed interlock location. Space the

screws 2" on center and position them so there are two screws

on each side of the interlocker. Drive the screws until the

head/washer contacts the fin, however do not sink the washer.

This will allow for movement of building material.