21

O

O

PERATING

PERATING

I

I

NSTRUCTIONS

NSTRUCTIONS

COMPLETE THE CHECK LIST (Page 9) PRIOR TO LIGHTING YOUR FIRST FIRE

FOLLOW THE ARROWS TO START YOUR APPLIANCE FOR THE FIRST TIME

IT IS CRITICAL FOR THE CORRECT OPERATION OF YOUR STOVE THAT THE FOLLOWING STEPS

BE PERFORMED! A pellet stove, like most things is life is NOT a plug and play appliance.

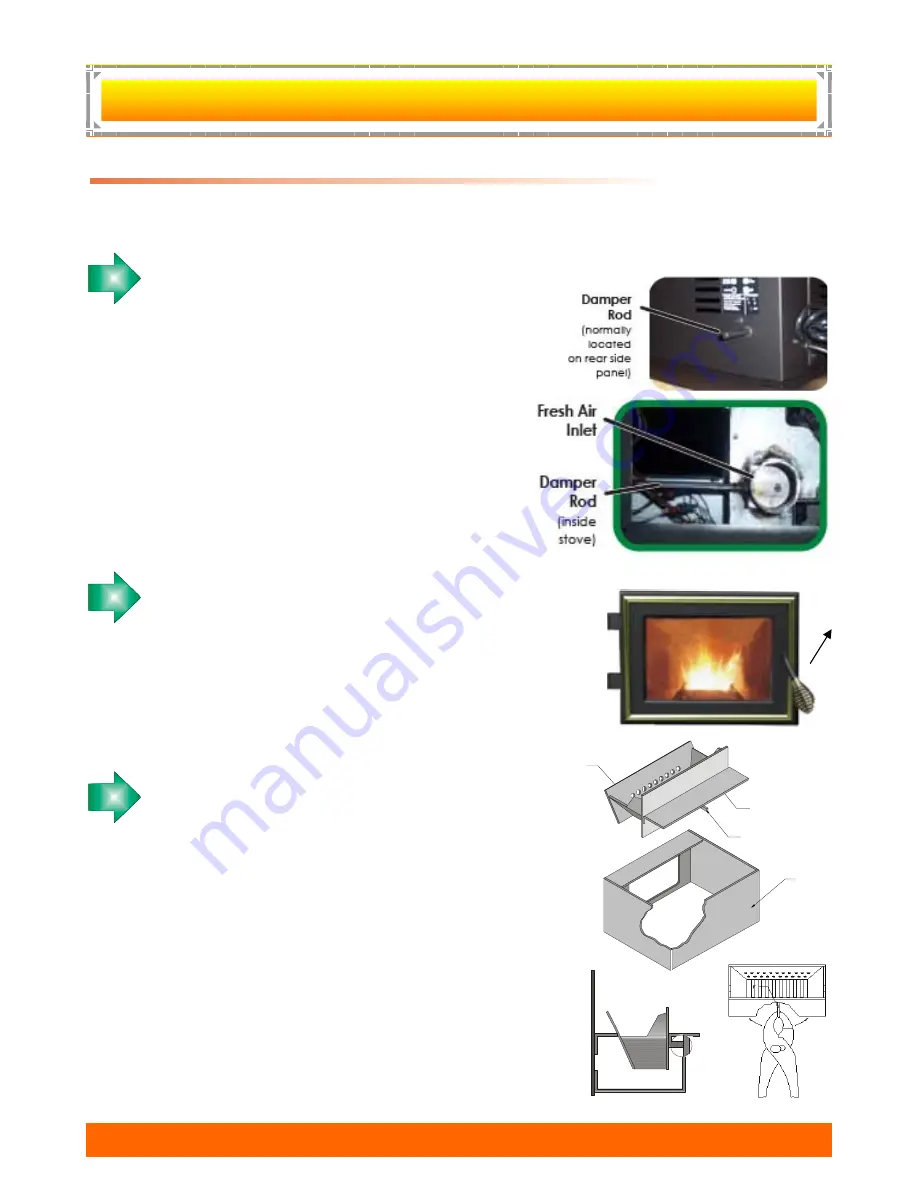

SETTING THE AIR INLET DAMPER

Because the appliance is made in one location and elevation,

then shipped, moved and installed to a different location, at a

different elevation, vented differently and then using different fuels. It is

not possible for the manufacture to factory set your stove to work

properly without some adjustments.

The damper helps to control the amount of airflow supplied for

combustion.

Damper

pushed in

all the way airflow is minimum.

Damper

pulled out

all the way airflow is increased.

To get the appliance started, push the air damper in all the

Way, then pull outward approximately 1/2”.

This may not be the final setting.

We will cover FINE TUNNING YOUR STOVE later in this manual.

OPENING AND CLOSING THE MAIN DOOR:

Open the stove door by rotating the handle COUNTER

CLOCKWISE, toward the TOP of the stove, until the handle is

about the 3 o’clock position. Swing door open to the

left.

Close the stove door by keeping the handle at the

3 o’clock position. Push the door firmly against the stove.

Rotate the handle downward to the 6 0’clock position to lock.

SEATING THE PELLET BURN GRATE:

Diagram A

The SUPER GRATE multi-Fuel Burn Grate comes in one piece: (B)

and sits in the Burn Pot (A)

Diagram B

Ensure the Multi-Fuel Burn Grate (A) is properly seated in

the burn pot and holes are free from obstructions .

The burn grate front lip must sit firmly on the top of the burn pot.

Diagram B and C

You may need adjust the spacer tab (C) if the burn grate fits loosely in

the burn pot or if the Igniter hole needs to be closer to the igniter.

To do so grasp the burn grate adjustment tab (C) with a pair of pliers

and bend it slightly inward or outward, until the burn grate top rest

tightly onto the burn pot and grate fits firmly, with slight play, in the

burn pot.

PelPro Home & Shop Heater www.pelprostoves.com 21

B

C

G

A

C

Diagram A

Diagram B

Diagram C

Summary of Contents for HHPP2

Page 40: ...40 ...