4

www.PennBarry.com

START-UP AND OPERATION

Start-up and operation

Carefully inspect the unit before start-up. All motor bearings

should be properly lubricated. All motor fasteners should be

securely tightened. Centrifugal wheel should be rotated by

hand to ensure free movement. (NOTE: Before placing hand

on centrifugal wheel or belts, lock out power source.) Check all

set-screws and keys. Tighten when necessary.

Check condition of belts and the amount of tension prior to

start-up. DO NOT overtighten, as bearing damage will occur.

Recommended belt tension should permit deflection of 1/64”

of the belt on each side of the belt measured halfway between

the pulley centerline. Exercise extreme care when adjusting

belts as not to misalign the pulleys. Any misalignment will

cause a sharp reduction in belt life and produce squeaky,

annoying noises. On units equipped with two or three groove

pulleys, adjustments must be made so that there is equal

tension on all belts (see Figure 1).

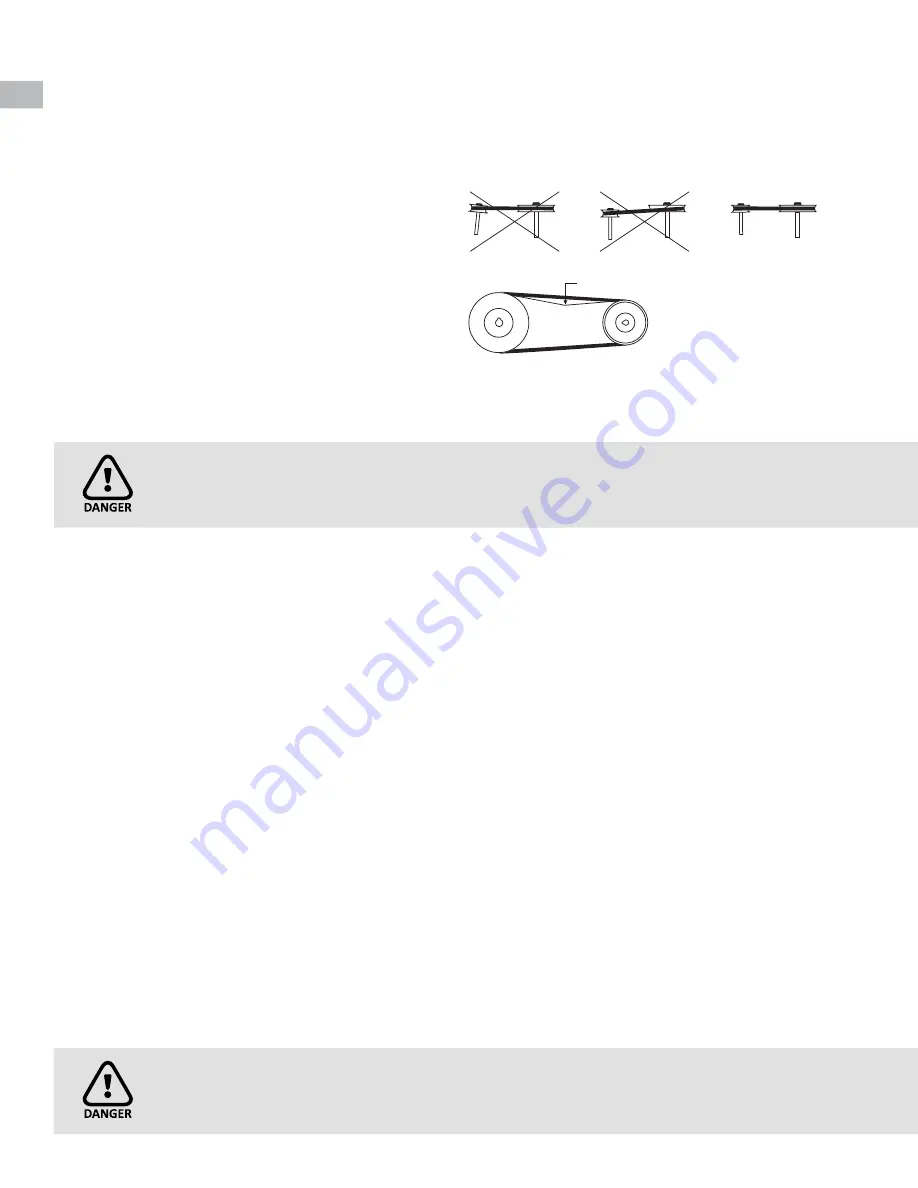

FIGURE 1: PULLEY ALIGNMENT

Whenever belts are removed or installed, never force belts over pulleys without loosening motor first to relieve belt

tension.

(On single phase motors, the terminal block must be set up in accordance with the nameplate instructions and/or wiring

diagram. This set up must match the line voltage. If the motor is multi-speed or multi-voltage, the winding leads must be

grouped and connected as shown on the motor wiring diagram. The line voltage must correspond with proper grouping

of motor leads. The wiring diagram must be followed explicitly or serious motor or starter damage will occur.)

Make sure inlets and approaches to the unit are free from obstruction. To ensure maximum air movement, adequate supply air must

be available.

When power lines are brought up to the unit, provide a generous amount of slack to allow for motor deflections and to permit

movement of motor for belt tension adjustments. Ground motor adequately and securely. Protect power lines from sharp objects.

Do not kink power line or permit it to contact hot surfaces, chemicals, grease or oil. Use only UL recognized electrical parts, rated

for proper voltage, load and environment.

Before putting fan into operation, complete the following check list:

1.

Lock out primary and secondary power source.

2. Make sure installation is in accordance with manufacturer’s instructions.

3. Check and tighten all fasteners.

4. Spin centrifugal wheel to see if rotation is free and the wheel doesn’t bind or rub.

5. Check all set-screws and keys; tighten if necessary.

6.

Check that torqued set screws have a colored Torque Seal mark indicating the correct torque has been applied.

7. Check belt or direct drive coupling for alignment (use recommended belt tension gauges).

8. Check belt for proper sheave selection.

9. Make sure there is no foreign or loose material in ductwork leading to and from fan or in the fan itself.

10.

Properly secure all safety guards.

11.

Secure all access doors to fan and ductwork.

12.

Check line voltage with motor nameplate.

13.

Check wiring.

Not to exceed 1/64” per inch of span

WRONG

WRONG

CORRECT