6

www.PennBarry.com

MAINTENANCE

Maintenance

Do not attempt maintenance on fan until the electrical supply has been completely disconnected. If a service switch has

not been provided, remove all fuses from the circuit and lock the fuse panel so they cannot be accidentally replaced.

Lubrication is a primary maintenance responsibility. Check all bearings periodically. Inspect belts for tightness. If the fan

is installed in a corrosive or dirty atmosphere, periodically clean the centrifugal wheel, inlet, motor housing and other

moving parts.

Fan Shaft Lubrication

Fan shaft bearing pillow blocks are furnished in either the prelubricated sealed for life type or the greasable type

depending on what was ordered. The prelubricated type requires no servicing for 7 to 10 years of normal use, and

the greasable type are factory greased eliminating the need for greasing initially. Follow the lubricating schedule

recommended by the factory. This practice should not supersede any safety considerations.

Lubrication Schedule

Always follow the bearing manufacturer’s recommended lubrication schedule. If none is available, use the following

general schedule:

1.

Under average conditions where ambient temperatures do not exceed 120°F, lubrication is required 1 to 2 times a

year.

2.

Under dirt laden atmosphere where there is a temperature range of 120°F to 150°F, lubrication is required from 3

to 6 times a year.

3.

Under extreme temperature conditions and extremely dirty atmospheres, lubrication should be scheduled at least

once or twice a month.

4.

Belt drive units maximum temperature should not exceed 160°F. Direct driven models have temperature range

stamped on motor.

Motor Lubrication

In general, standard motors are furnished with prelubricated, sealed-for-life ball bearings which require no lubrication

for 7 to 10 years of normal service. Where motors have been ordered with greasable bearings, these bearings are factory

lubricated and require no attention for one year under normal conditions. If grease relief fittings are provided, remove

them when performing maintenance to allow grease to flow out. Whenever possible, apply grease while the motor

is running. This practice should not supersede any safety considerations. DO NOT OVERGREASE, as most lubricants

deteriorate motor windings, thereby reducing motor life.

Use low pressure grease guns only. High pressure guns tend to blow out or unseat bearing seals, leaving the bearing

open to collect grime, dust and foreign particles.

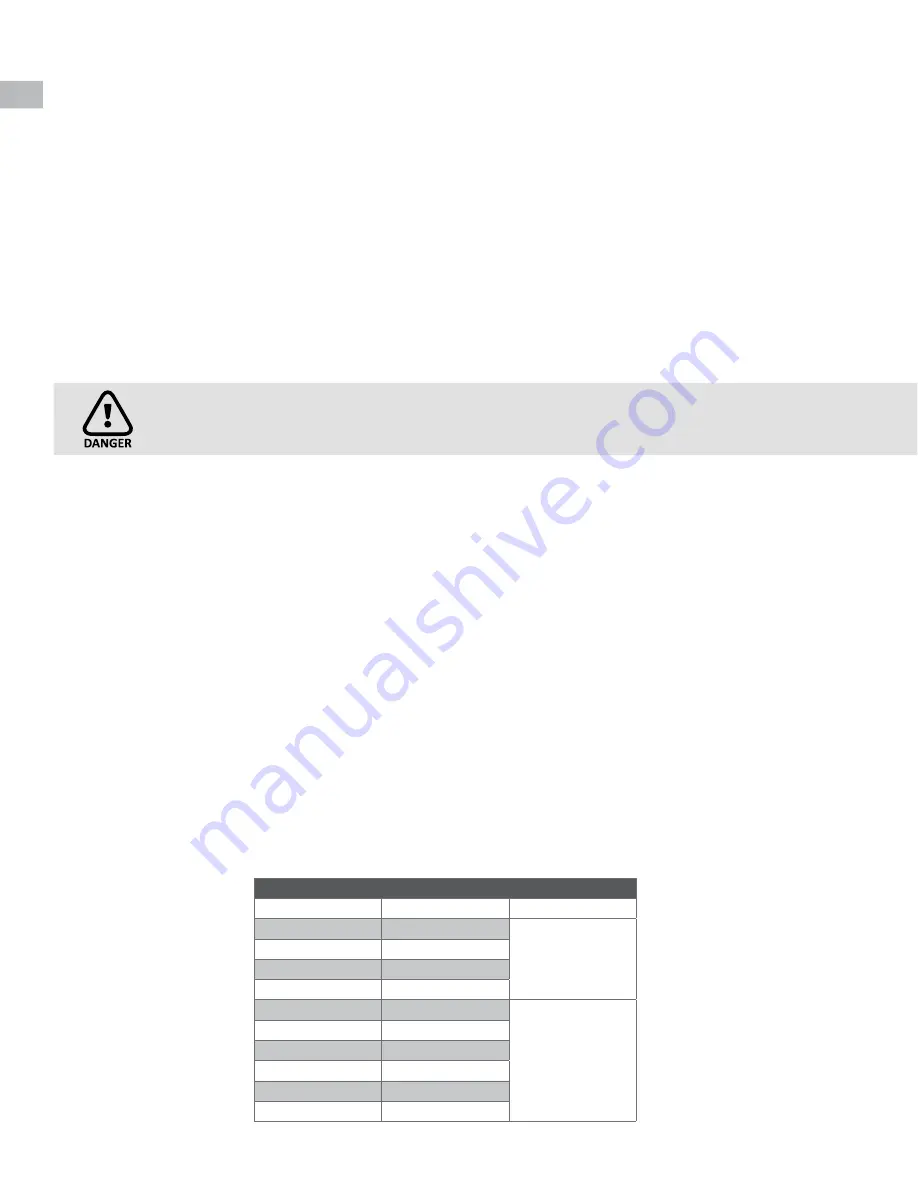

RECOMMENDED LUBRICANTS

Manufacturer

Product

Temperature Range

BP

LG-#P-1

Below 32°F

(0°C)

Gulf

Gulfcrown EP-1

Imperial Oil

Unirex EP-1

Shell

Alvania R-1

BP

Energrease, MPMK11

32°F to 150°F

(0°C to 66°C)

Gulf

Gulfcrown EP-2

Imperial Oil

Unirex EP-2

Shell

Alvania R-3

Sun Oil

Sun Prestige 42

Texaco

Regal AFB2