5

!

!

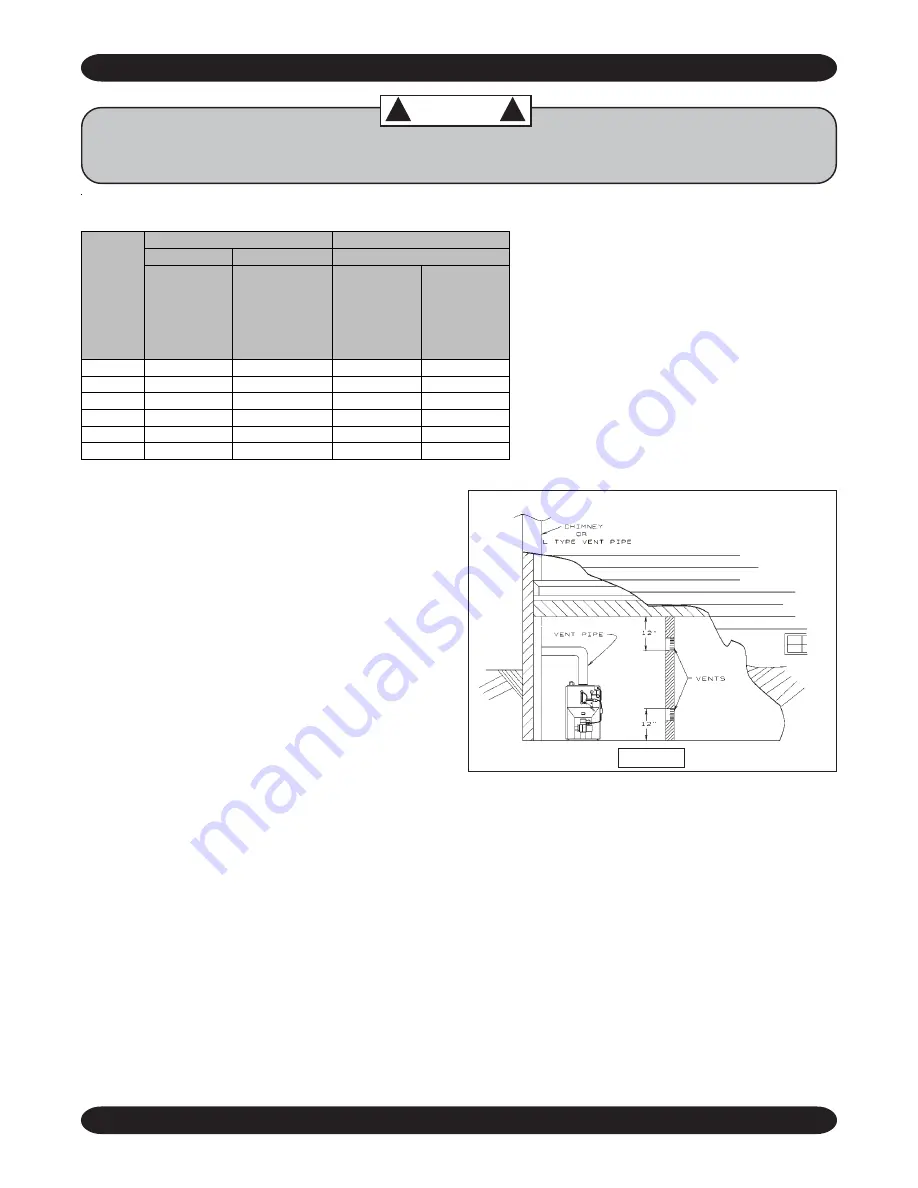

VENTILATION AND COMBUSTION AIR

WARNING

Air openings to combustion area must not be obstructed. By following the instructions below,

adequate combustion air can be maintained.

COMBUSTION AIR REQUIREMENTS

(Minimum Opening Requirement)

Outside

Inside

Combustion

Air 1 Sq.

In./5000

BTU/Hour

(Step 4)

Combustion Air

1 Sq. In./1000

BTU/Hour (Min.

100 Sq. In.)

(Fig. 1)

Vertical

Ducts 1 Sq.

In./4000

BTU/Hour

(Fig. 2 & 3)

Horizontal

Ducts 1 Sq.

In./2000

BTU/Hour

(Fig. 4)

91,000

19

100

23

46

140,000

28

140

35

70

175,000

35

175

44

88

210,000

42

210

53

106

245,000

49

245

61

122

280,000

56

280

61

140

* A space w hose volume is not less than 50 cubic feet per 1000 BTU/Hour of all

appliances installed in that space (cubic feet of space = height x w idth x length)

** A space w hose volume is less than 50 cubic feet per 1000 BTU/Hour of all

appliances installed in that space (cubic feet of space = height x w idth x length)

BTU/Hr

Input

Unconfined Area*

Confined Area**

Outside Combustion Air

1. Ventilation of boiler room must be adequate

enough to provide sufficient air to properly support

combustion and venting.

2. When the boiler is located in an unconfined space

in a building of conventional construction frame,

masonry or metal, infiltration normally is adequate to

provide air for combustion and ventilation. However,

in any building which has been altered to conserve

energy or to minimize infiltration, the boiler area

should be considered as a confined space. If there is

any doubt, install air supply provisions for combustion

and ventilation in accordance with section 5.3, Air for

Combustion and Ventilation, of the NFPA 54 1988

code, the recommendations that follow, or applicable

provisions of the local building codes.

3. When the boiler is installed in an unconfined

space, in a building of unusually tight construction,

air for combustion and room ventilation must be

obtained from outdoors or from spaces freely

communicating with the outdoors. A permanent

opening or openings having a total free area of not

less than 1 square inch per 5,000 BTU per hour of

total input rating of all appliances shall be provided.

Ducts may be used to convey make-up air from the

outdoors and shall have the same cross-sectional

area of the openings to which they are connected.

4. When air for combustion and room

ventilation is from inside buildings, the

confined space shall be provided with two

permanent openings, one starting 12 inches

from the top and one 12 inches from the

bottom of the enclosed space. Each opening

shall have a minimum free area of 1 square

inch per 1,000 BTU per hour of the total

input rating of all appliances in the enclosed

space, but must not be less than 100 square

inches. These openings must freely

communicate with the interior areas having

adequate infiltration from the outside.

(Figure 1)

5. When the boiler is installed in a confined space

and all air is provided from the outdoors, the confined

space shall be provided with two permanent openings,

one commencing within 12 inches from the top and

one commencing 12 inches from the bottom of the

enclosure. The openings shall communicate directly,

or by ducts, with the outdoors or spaces (crawl or

attic) that freely communicate with the outdoors.

One of the following methods must be used to

provide adequate air for ventilation and combustion.

A. When directly communicating with the outdoors,

each opening shall have a minimum free area of

1 square inch per 4,000 BTU per hour of total

input rating of all equipment in the enclosure.

(Figure 2)

FIGURE 1