8

!

!

VENTING SYSTEM INSPECTION & INSTALLATION

WARNING

Boiler is to be vented by natural draft and shall

not be connected into any portion of a

mechanical draft operating system under a

positive pressure.

Inspect chimney to make certain it is constructed

according to the latest revision of the NFPA 211.

Local regulations may differ from this code and

should be checked. Where there is a conflict, the

local code will prevail.

The boiler must be installed into a chimney which

has a masonry or metallic chimney liner.

An unlined chimney will have leaks that will cause

poor chimney performance (no draft), and could

result in a positive pressure in the combustion

chamber.

Horizontal portions of the venting system should not

exceed 10 feet in length. Horizontal lengths over 10

ft. will have a negative effect on the chimney

performance.

The chimney should extend at least 2 ft. above any

portion of the building within 10 ft.

(Figure 9)

It should

produce a -.02 inch W.C. draft in the combustion

chamber. See "Chimney or Vent Sizes" chart for

recommended minimum and maximum chimney or

vent sizes.

Inadequate draft will cause improper combustion,

resulting in dirty flue ways and high fuel bills.

CHIMNEY OR VENT SIZES

MIN

MAX

MIN

MAX

MIN

MAX

91,000 - 140,000

6

8

8x8

8x8

15

40

175,000 - 210,000

7

8

8x8

8x10

15

40

245,000 - 280,000

8

10

8x8

8x12

15

50

315,000

8

10

8x8

8x12

15

50

385,000

8

10

8x8

8x12

15

50

BTU/HR INPUT

ROUND

INCHES

SQUARE

INCHES

HEIGHT

(FT)

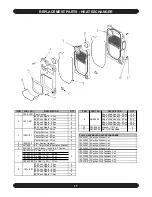

FIGURE 9

Connect flue pipe same size as boiler outlet to

chimney, sloping upward continuously toward the

chimney approximately 1/4" per foot. Bolt or screw

joints together to avoid sag.

If an oil fired water heater is vented into the same flue

as the boiler, provide a separate hole into the chimney

whenever possible. When this isn’t possible, use a

“Y” connection in the flue pipe, using a separate draft

regulator for each unit. When a chimney will not

provide adequate draft to handle the input from the

water heater and boiler simultaneously, wire the

units so that only one will operate at a time, favoring

the water heater.

OIL TANK AND PIPING

Oil tank and piping should be installed in accordance

with the National Board of Fire Underwriters and

local regulations. Oil storage tank, vent, fill pipe and

caps should be as prescribed by local codes. In no

case should the vent pipe be smaller than 1-1/4"

I.P.S. The fill pipe should not be less than 2" I.P.S.

The suction line from the tank to the burner should be

one continuous piece of tubing to prevent air enter-

ing the line. The suction line, must be 3/8" O.D.

copper tubing for runs of 50 feet or less, and 1/2"

O.D. for longer runs. An oil return line, same size as

the suction line, must be used on any installation

where the bottom of the tank is below the fuel unit of

the burner. Oil lines should be buried or otherwise

protected from mechanical injury. Flare fittings on all

oil lines are recommended. Compression fittings on

the suction line often allow air to be drawn into the

fuel pump, making it difficult to maintain oil pressure

at the nozzle. Do not run overhead fuel lines from

tank to oil burner.

Fuel pump connections and by-pass should be made

according to instructions attached to the fuel pump.