9

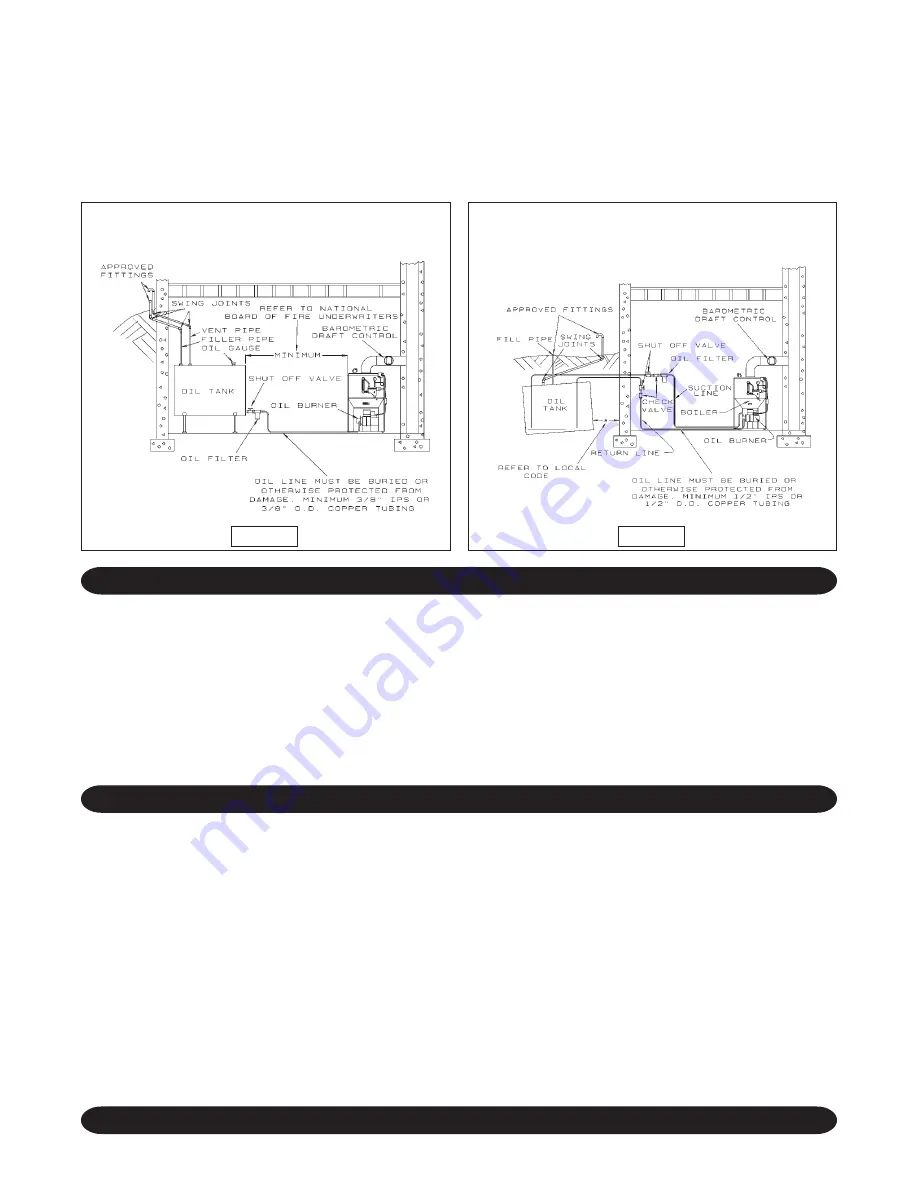

If tank is more than 20' from the boiler, a two stage

fuel unit should be installed in place of the single

stage pump supplied as standard equipment with

the burner. Make certain the rotation and speed are

the same and the pump is suitable for the burner

horsepower rating.

FIGURE 10

TYPICAL INSTALLATION -

SINGLE PIPE OIL SYSTEM

FIGURE 11

TYPICAL INSTALLATION -

TWO PIPE OIL SYSTEM

An oil line filter and shut-off valve should be installed

in the suction line. Shut-off valves should be installed

in both the suction and return lines at the burner for

convenience in servicing burner. Allow extra tubing

at burner so burner may be removed from boiler for

cleaning without disconnecting tubing.

(Figures 10-

11)

An optional flexible oil line is available.

ELECTRICAL WIRING

Electrical wiring must conform with the latest revi-

sions of the National Electrical Code, ANSI/NFPA

No. 70, and/or local authority having jurisdiction.

1. When an external electrical source is utilized,

the boiler, when installed,

MUST BE

electrically

grounded in accordance with these requirements.

2. Install a fused disconnect switch between

boiler and meter at a convenient location.

3. When the boiler is equipped with self-ener-

gized controls, no outside source of electric power

shall be connected to the circuit of this system.

(See "Steam Wiring W/MM #67 Mechanical

LWCO" on next page.)

THERMOSTAT INSTALLATION

1. Thermostat should be installed on an inside wall

about four feet above the floor.

2.

NEVER

install a thermostat on an outside wall.

3. Do not install a thermostat where it will be affected

by drafts, hot or cold pipes, sunlight, lighting fixtures,

television, fireplaces, or chimneys.

4. Check thermostat operation by raising and lower-

ing thermostat as required to start and stop the

burner.

5. Instructions for the final adjustment of the thermo-

stat are packaged with the thermostat (adjusting

heating anticipator, calibration, etc.).