Doc

Ref:

EICT

Set-up

Guide

P201754

issue

5

January

2009

Insert connector of

PWM

card onto the vacant pins of header

JP2

. Monitor the

PWM

output (Terminal 5) with

respect to GND (Terminal 6) using an oscilloscope. Power up the

EICT/EICTM

. Check that output has 10-90%

duty cycle over the the required displacement of the transducer, adjust zero and gain trim pots if necessary.

(Equivalent to 0.5 to 4.5Vdc output).

Step 12 - Final setup

•

After configuration, switch off the power to

EICT/EICTM

. Remove DMM or oscilloscope connections.

Replace the lid using screws removed, ensuring all gaskets are present and in the correct place.

Recommended tightening torque for the lid screws is 2Nm.

•

Optional, but recommended - use an indelible pen to mark the configuration settings you have selected,

in the appropriate label area shown on the

EICT/EICTM

housing cover. (EICT type; Voltage output range [if

applicable]; transducer type)

•

The transducer and

EICT/EICTM

are now ready for use. Refer to

EICT/EICTM

technical data

sheet/brochure for full specification, mounting options and dimensions.

Additional Notes:

1

Current Module

(CM)

(4 - 20mA) and Pulse Width Modulation

(PWM)

'set-up' is unaffected by Dual

Supply option. Continue to follow set-up guide steps.

2

Recommended connections, but optional. Consult your Systems Engineer should other options be

required.

3

Make a note of, and check, the transducer cable colour codes (see Fig. 5) relative to the assigned

connector termination identities, to enable the

EICT/EICTM

to be correctly connected.

4

Cable diameter must be between 2.5 and 6.0mm diameter to maintain IP66 rating of the

EICT

housing.

Cable diameter must be between 3.0 and 8.0mm diameter to maintain IP68 rating of the

EICTM

housing.

Make off cable elements to the connector.

5

Rapid integrity check for connector and/or transducer.

EICT/EICTM

must be disconnected from the transducer to carry out following check!

Using a DMM, set to the resistance range: (See Fig. 5 for transducer cable colour coding)

i)

Measure between connector terminals assigned to transducer 'yellow' and 'blue'. Value should lie

between 40

Ω

and 170

Ω

.

ii) Measure between connector terminals assigned to transducer 'green' and 'yellow' and/or 'blue'.

Value should be 'open circuit'.

iii) Measure between connector terminal assigned to 'green' and the transducer body. Value should be

'short circuit'.

iv) 'Screen', if used - Connector terminal assigned to 'screen' should be 'open circuit' to all the other

connector terminations and transducer body unless otherwise specified by your Systems Engineer.

6

Any problems or questions should be e-mailed to sales@pennyandgiles.com

For technical assistance contact your local distributor or Penny+Giles at

UK

Tel: +44 (0)1202 409409

Email: sales@pennyandgiles.com

USA

Tel: +1 562 531 6500

Email: us.sales@pennyandgiles.com

Web:

www.pennyandgiles.com

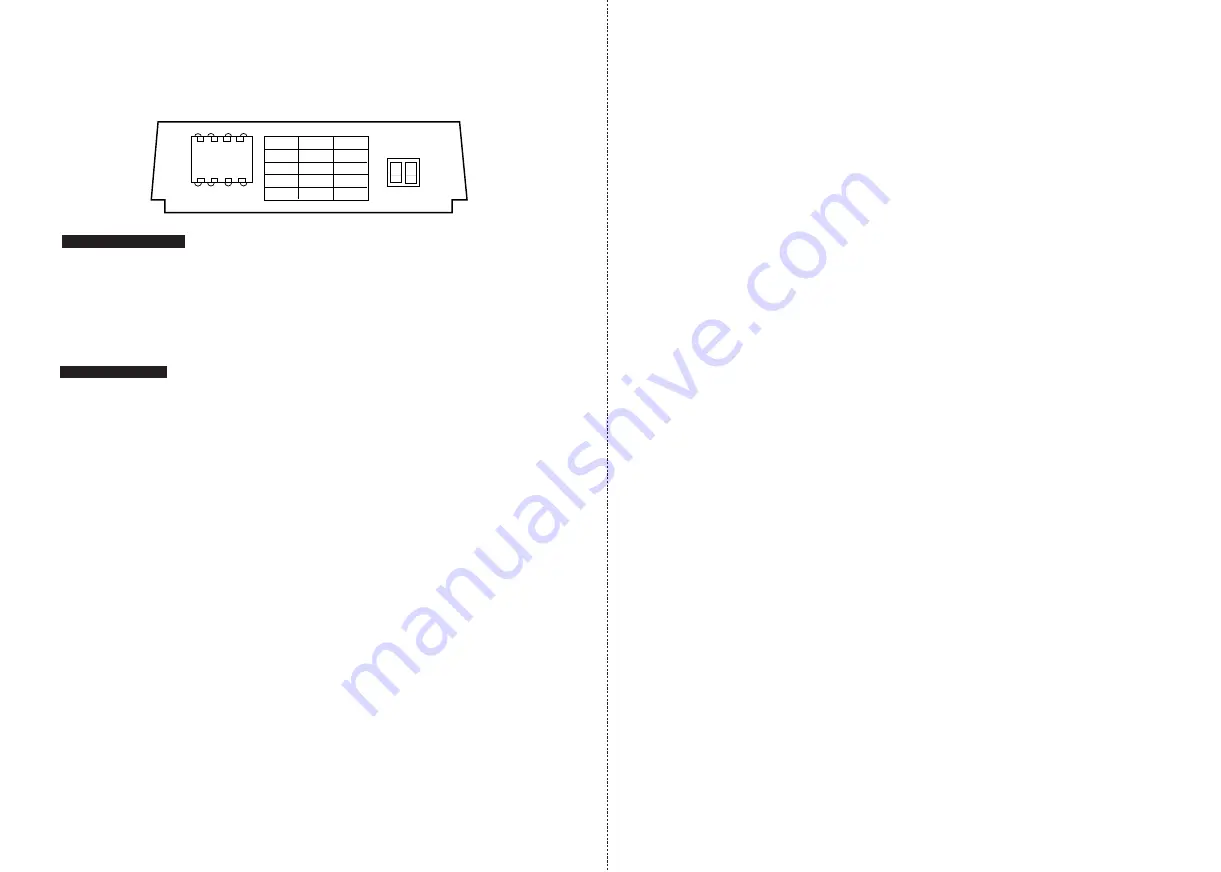

Fig. 6

A

B

Hz

OFF

OFF

1000

ON

OFF

310

OFF

ON

130

ON

ON

100

S1

ON

7 1

8 5

A B