13

Issue 1

–

ER - Oct 2019

Survey, Installation and Commissioning

All Penny Hydraulics lifts are manufactured to a high standard and can be installed in many diverse

situations. Since no two applications are the same, this lift is custom-made following a site survey and

risk assessment.

It is assembled in the factory and delivered on site and cannot be altered. It is therefore essential that

when the original survey is carried out, that all dimensions and facts that may affect installation are

correct. The following section explains the important points at various situations.

Survey

A trained person must perform the survey and complete a site assessment form, as it is part of the

installation risk assessment and layout evaluation. A quotation may be derived from an architect’s

drawing, but knowledge of the intended use and a site survey is essential as the job progresses to take

full account of the special requirements of the task and location.

Installation

All installations must be carried out by qualified engineers trained in the method of installation and

approved by Penny Hydraulics. It is important to note that should a non-approved engineer on

installation cause damage or fault, this could invalidate the warranty.

•

Clear the working area.

•

Check all dimensions before unloading.

•

Manoeuvre the lift into position noting that this will normally require a crane mounted on the

delivery vehicle or chain blocks fixed inside the building. Lifts can be made in two or more

sections to aid manual handling and then assembled in position.

•

Bolt the lift to the floor and back wall or framework. It is essential that a sound fixing is

obtained at the top of the lift. Welding may be required.

•

Locate and mount the power pack such that the operator is in a safe position at the bottom but

has sight of the lift.

•

Erect any guarding necessary as previously agreed. This is sometimes done earlier in the

installation process depending on site circumstances and how the lift fits into the structure.

•

Couple all electric and hydraulic connections. They must all be fastened securely and neatly

back. It is possible to commission lifts on a temporary supply and then an electrician couple

into a permanent supply prior to lift going into service.

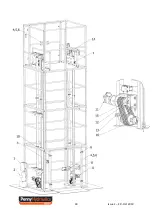

Summary of Contents for MezzLift

Page 17: ...16 Issue 1 ER Oct 2019 General Arrangement...

Page 19: ...18 Issue 1 ER Oct 2019...

Page 20: ...19 Issue 1 ER Oct 2019 Hydraulic Diagram...

Page 21: ...20 Issue 1 ER Oct 2019 Electrical Diagrams...

Page 22: ...21 Issue 1 ER Oct 2019...

Page 23: ...22 Issue 1 ER Oct 2019...

Page 24: ...23 Issue 1 ER Oct 2019...

Page 25: ...24 Issue 1 ER Oct 2019...