Copyright 2010 DTX International

21

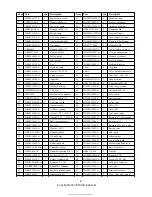

Item

Part

Qty

Description

Item

Part

Qty

Description

1

DJ188F-16121-C

1

Starter comp, recoil

43

DJ190FD-14100-A

1

Carburetor assy.

2

GBT5789-B6-8

3

Flange bolt M6

×

8

44

DJ188F-14003-B

1

Packing, carburetor

3

DJ188F-16120-A

1

Fan, cover comp

45

DJ188FD-14004-A

1

Insulator, carburetor

4

GBT5789-B6-12

13

Flange bolt M6

×

12

46

GBT6177/10-N-6

2

Flange nut M6

5

DJ188F-11012-A

1

Shroud comp

47

DF6500H-14205-A

1

Stay, air cleaner

6

DJ168F-11039-A

3

Clip. Wire darkness

48

DJ188FD-14203-A

1

Case comp, air cleaner

7

DJ168F-16118-A

1

Grommet drain hole

49

DJ188FD-14202-A

1

Retainer Filter Element

8

DJ188F-18600-A

1

Start motor

50

GB/T6177-2000

6

Flange nut M5

9

GBT16674

2

Flange bolt M8

×

35

51

DJ188FD-14204-A

1

Cover comp, air cleaner

10

GBT6177-N-14

1

Flange nut M14

52

DJ188FD-14207-A

2

Clip, air cleaner ware

11

DJ188F-16000-A

1

Pulley, starter

53

DJ188FD-14201-A

1

Element, air cleaner

12

DJ188F-16002-A

1

Fan, cooling

54

DJ188FD-14206-A

1

Seal, air cleaner

13

DJ168F-12104-A

1

Key

55

DJ188F-14005-A

1

Packing, insulator

14

DJ188F-16200-G

1

Flywheel comp

56

14601

4

Clip, tube

15

DJ188F-11014-A

2

Oil seal, 35

×

52

×

8

57

14013

1

Valve, dashpot check assy.

16

DJ190F-11100-D

1

Crank case assy.

58

14034

1

Tube, fuel

φ

45

×

165

17

DJ168F-18300-A

1

Amplifier

59

DJ188FD-11013-A

1

Tube, breather

18

DJ188F-11004-A

2

Bolt, drain lug

60

GBT5787-B10-80

4

Flange bolt M10

×

80

19

DJ188F-11005-A

2

Washer, drain lug

61

DJ188F-11200-B

1

Head comp, cylinder

20

DF2500H-34118-A

1

Clip, wire

62

DJ188F-14002-A

2

Bolt head, M8

×

48

21

34218-001

1

Idle Control Component

63

DJ168F-18500-A

1

Plug, spark

22

GBT5789-B6-25

2

Flange bolt M6

×

25

64

DJ190F-13100-C

1

Camshaft assy.

23

DJ188FB-18106-A

1

Cord stop switch

65

DJ190F-13009-A

2

Lifter, valve

24

DJ188F-11017-A

1

Grommet cord

66

DJ188F-13001-A

1

Valve, IN.

25

DJ188F-18100-C

1

Coil assy. ignition

67

DJ188F-13002-A

1

Valve, EX.

26

DJ188F-15009-A

Oil seal,

Φ

8

×φ

14

×

5

68

DJ188F-13011-A

1

Seat, valve spring

27

DJ188F-11014-A

2

Oil seal,

Φ

35

×Φ

52

×

8

69

DJ188F-13005-A

1

Retainer, EX. Valve spring

28

DJ188F-15001-A

1

Shaft, governor arm

70

DJ188F-13006-A

1

Rotator, valve

29

DJ188F-15003-A

1

Pin, lock

71

DJ188F-13004-A

1

Retainer, IN. Valve spring

30

DJ188F-15002-A

1

Washer,

Φ

8

×

1

72

DJ188F-13003-A

2

Spring, valve

31

GB/T6177-2000

1

Flange nut M10

73

DJ190F-13008-A

2

Rod, push

32

DJ188F-18202-A

1

O-ring,14mm

74

DJ188F-11011-A

1

Exhaust piper

33

DJ188F-18200-A

1

Oil Sensor

75

DJ188F-11300-B

1

Cover comp, head

34

DJ188F-12004-A

1

Balancing Shaft

76

DJ188F-11016-A

1

Washer comp head cover

35

DJ190F-12100-BB

1

Crankshaft comp

77

DJ188F-11015-A

1

Bolt, head cover

36

GB276-89-6207

2

Radial ball bearing (6207)

78

GBT6175-N-8

2

Nut M8

37

DJ188F-11009-A

2

Pin, dowel, 12

×

20

79

DJ188FD-14009-B

1

Pipe comp EX.

38

DJ190F-11010-C

1

Casket, cylinder head

80

DJ188FD-14010-A

1

Casket (B) EX. Pipe

39

DJ188FD-14001-A

2

Bolt head, 8

×

106

81

DJ188F-13300-A

1

Plate, push rod guide

40

DJ188F-14027-A

2

Gasket,Air Cleaner

82

DJ188F-13202-A

2

Bolt, pivot

41

DJ188F-14012-A

1

Stay assy. Manual choke

83

DJ188F-13201-A

2

Arm, valve rocker

42

DJ188F-14501

1

Grommet fender

84

DJ168F-13203-A

2

Nut,

Arm, valve rocker