4

ITEM

A-03-343

DATED

NOVEMBER 2012

SUPERCEDES

MARCH 2011

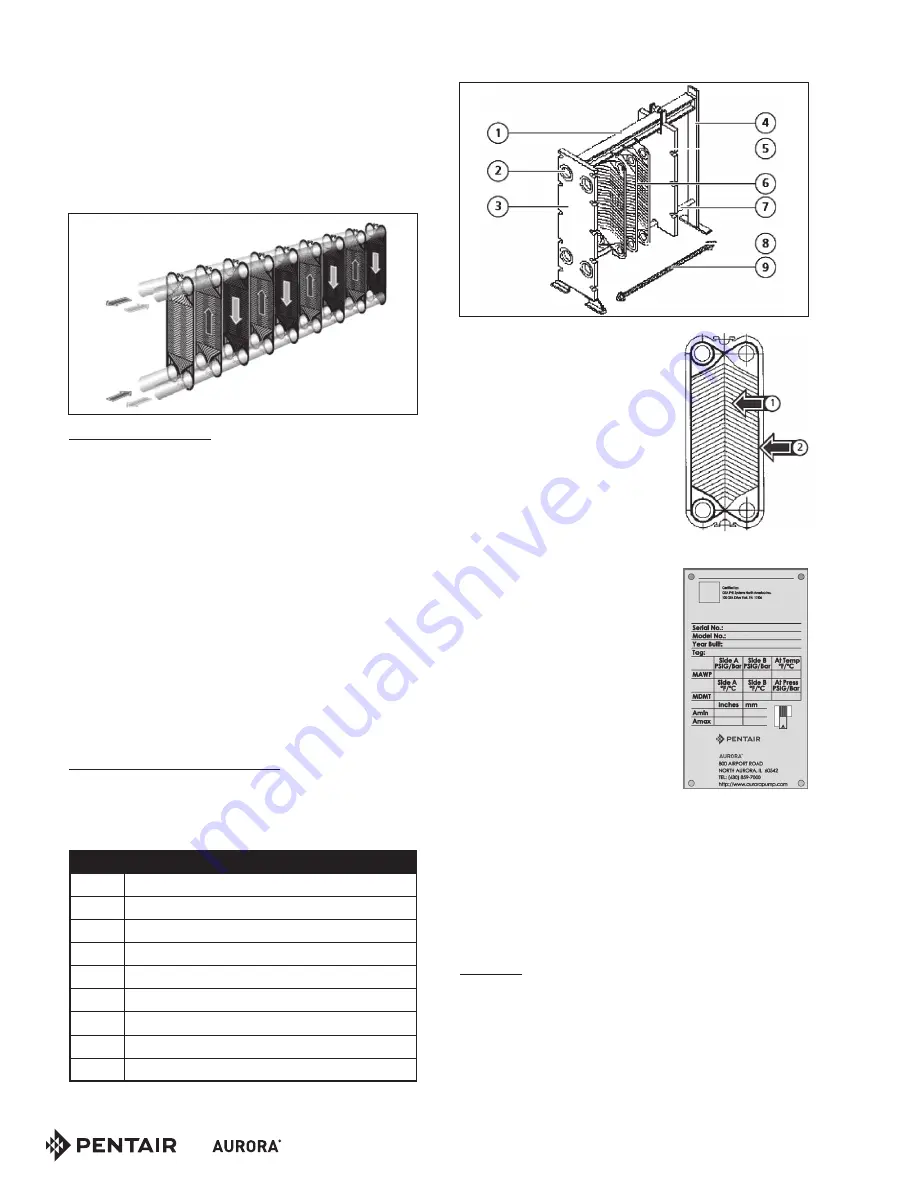

Usually single-pass plate heat exchangers are used (shown

below). In the case of single-pass plate heat exchangers, all feed

and return pipes are connected to the fixed pressure plate.

Close temperature differences between the media may demand

the use of multipass plate heat exchangers. In the case of multi-

pass plate heat exchangers, the connection pipes are placed at

the fixed frame plate and at the pressure plate.

INTENDED PURPOSE:

This heat exchanger has been specially designed and

manufactured for your specified operating conditions

concerning pressure, temperature, flow rates, and type of

flow media. If a change in the specified operating conditions

becomes necessary, Aurora should be consulted. The heat

exchanger should be operated only under new operating

conditions after appropriate changes have been made.

Intended use includes:

1. Adhering to the valid laws, decrees, regulations, directives

and other rules for the installation site.

2. Following all safety instructions of these operating

instructions.

3. Adhering to a regular inspection and maintenance plan.

NOTE: Aurora accepts no liability for damage caused by

deviations from the specified operating conditions for the plate

heat exchanger.

OVERVIEW AND DESCRIPTION:

BASIC ANATOMY. The following figure represents the basic

structure of a plate heat exchanger. The actual design depends

on the application.

Number

Component

1

Upper (or Carry) Beam

2

Piping Connections

3

Fixed Pressure Plate

4

Support Leg

5

Loose Pressure Plate

6

Heat Transfer Plates

7

Lower (or Guide) Beam

8

Gaskets

9

Tie Rod Assembly

The plate pack consists of contoured

heat exchanger plates (1) and the

corresponding gaskets (2) of varying

number and arrangement. Refer to the

flow diagram for specific instructions

as to the arrangement of the plates and

gaskets in the plate pack.

IDENTIFICATION. Each Aurora

gasketed plate heat exchanger is

provided with a nameplate that

complies with ASME Section VIII

requirements. It is fastened to the

outside of the fixed pressure plate of

the heat exchanger.

Here you’ll find information on:

1. Heat exchanger model

2. Serial no.

3. Max. Allowed Working Pressure

(psig/bar g)

4. Permissible temperatures

(°F and °C)

5. Date of manufacture

6. Compression dimensions

a. “a max.” / “a min.”

b. Listed in both inches and mm

7. Additional details (project specific)

8. U-Stamp (if applicable)

Each plate heat exchanger is supplied

with a dimension sheet and a flow diagram.

The dimension sheet shows the external dimensions as well as

details of the type, size and position of the pipe connections.

The flow diagram shows the plate arrangement and type of plate

heat exchanger, the plate material of the plate heat exchanger,

the plate thickness as well as the gasket material and the part

numbers.

FRAMES:

Aurora plate heat exchangers are available in different

application-specific frame designs. There are two basic designs,

BY and CY. The BY design is especially employed for longer

plate packs.

The structural steel frames are protected against corrosion by a

weather-protective multicoat paint. The tie rod assemblies are

made of high-strength alloy steels.