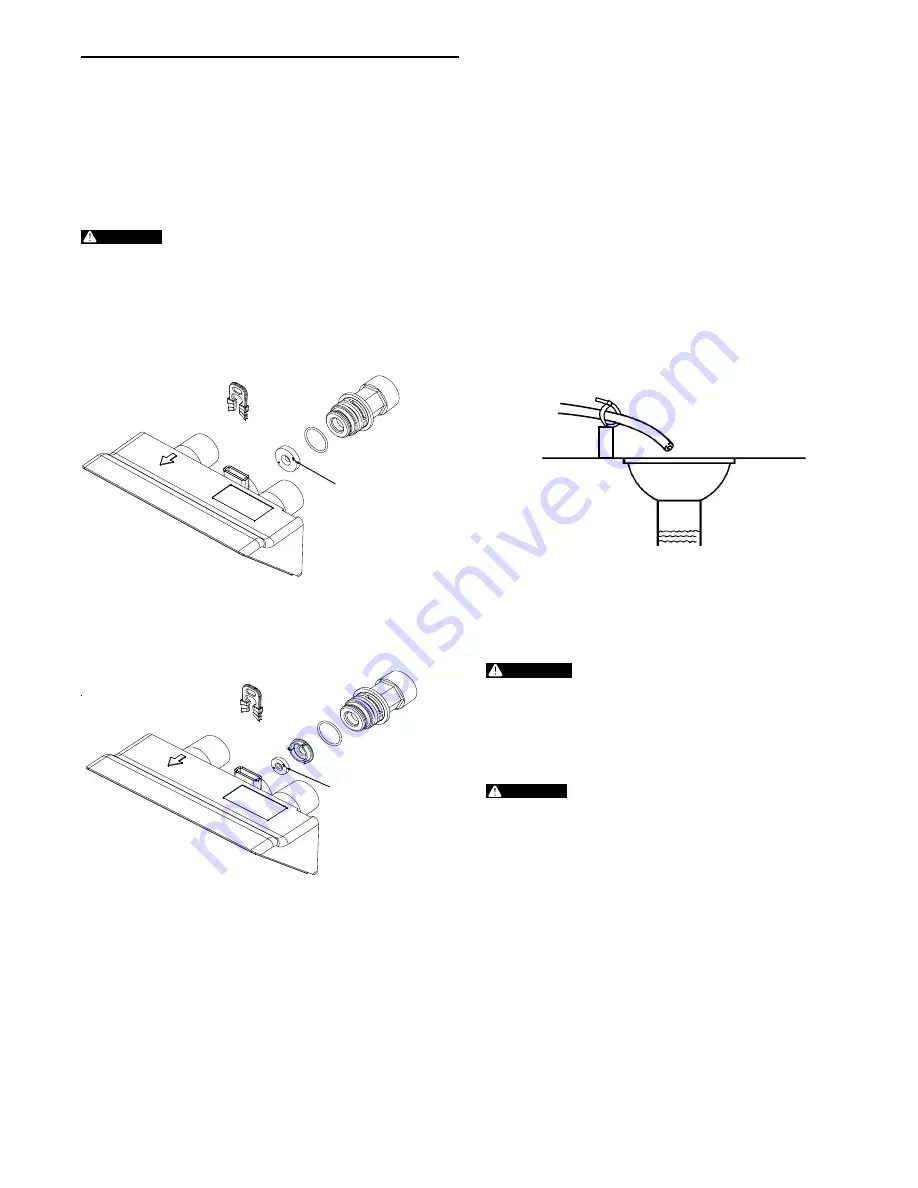

Firmly insert connector into the valve body. Press locking clip

into position. Make certain the clip is fully engaged.

To remove a clip:

1. Turn off water and release water pressure at the valve.

2. Push the water line connectors into the valve body. This will

help release O-rings that may have seated in place.

3. Remove the clip by inserting a flat blade under the top

center of the clip and lifting (prying up) (Figure 4 Connector

Assembly).

WARNING:

Do not use pliers to remove a clip. It is likely

the clip will break.

Drain Line Flow Control

The drain line flow control (DLFC) requires assembly

(Figures 4 and 5).

Install washer with printed

lettering facing the valve body.

1 Inch Drain Line Flow Control

Rates 8 - 20 GPM

Figure 5 - 1" Drain Line Flow Control

Install washer with printed

lettering facing the valve body.

3/4 Inch Drain Line Flow Control

Rates 4 - 7 GPM

Figure 6 - 3/4" Drain Line Flow Control

Note: Install DLFC washer with printed lettering facing the

valve body.

EQUIPMENT INSTALLATION

continued

Drain Line Connection

NOTE: Standard commercial practices are expressed here.

Local codes may require changes to the following

suggestions. Check with local authorities before

installing a system.

4. Use appropriate fittings to connect tubing to the DLFC

connection on valve.

5. The drain line may be elevated up to 6 feet (1.8 m) providing

the run does not exceed 15 feet (4.6 m) and water pressure

at the filter is not less than 40 psi (2.76 bar). Elevation can

increase by 2 feet (61 cm) for each additional 10 psi (.69 bar)

of water pressure at the drain connector.

6. Where the drain line is elevated but empties into a drain

below the level of the control valve, form a 7 inch (18 cm)

loop at the far end of the line so that the bottom of the loop

is level with the drain line connection. This will provide an

adequate siphon trap.

7. Secure the discharge end of the drain line to prevent it from

moving.

Right Way

Figure 7 Drain Line Connection

NOTE:

Waste connections or drain outlet shall be designed

and constructed to provide for connection to the

sanitary waste system through an air gap of two

pipe diameters or one inch (22 mm), whichever is

larger.

WARNING:

Never insert drain line directly into a drain,

sewer line, or trap (Figure 7 Drain Line

Connection). Always allow an air gap between

the drain line and the wastewater to prevent

the possibility of sewage being back-siphoned

into the filter.

Electrical Connection

WARNING:

This valve and control are for dry location use

only unless used with a Listed Class 2 power

supply suitable for outdoor use.

The 363 controller operates on 12-volt alternating current

power supply. This requires use of the an AC adapter with your

system.

Make sure power source matches the rating printed on the AC

adapter.

4002493 Rev A

4002492 Rev A

Autotrol

®

363 Demand Automatic Filter Valve • 5