SYSTEM STARTUP

The system will now need to be placed into operation. Please

review MANUALLY INITIATING A CLEANING CYCLE on page

7 before attempting startup.

1. With the supply water for the system still turned off,

position the bypass valve to the “not in bypass” (normal

operation) position.

2. Press and hold the button on the controller for three

seconds. This will initiate a manual cleaning cycle, and

cycle the valve to the backwash position.

3. Filling the media tank with water:

A. With the system in backwash, open the water supply

valve very slowly to approximately the 1/4 open position.

Water will begin to enter the media tank. Air will begin

to be purged to drain as the media tank fills with water.

WARNING:

If opened too rapidly or too far, media may

be lost out of the tank into the valve or the

plumbing. In the 1/4 open position, you should

hear air slowly escaping from the valve drain

line.

B. When all of the air has been purged from the media

tank (water begins to flow steadily from the drain line),

open the main supply valve all of the way. This will purge

any remaining air from the tank.

C. Allow water to run to drain until the water runs clear

from the drain line. This purges any debris from the

media bed.

D. Turn off the water supply and let the system stand for

about five minutes to allow any trapped air to escape

from the media tank. Turn on the water supply after five

minutes. Check for leaks.

The system is now fully operational.

INSTALLATION CHECKLIST

___ Read the owner's/installation manual?

___ Follow all safety guidelines in the manual?

___ If metal pipe was used, did you restore the electrical ground?

___ Securely install drain hose to an approved drain?

___ Perform a leak test?

___ Move the bypass valve to service?

___ Start a cleaning cycle?

CONTROL OPERATION AND LAYOUT

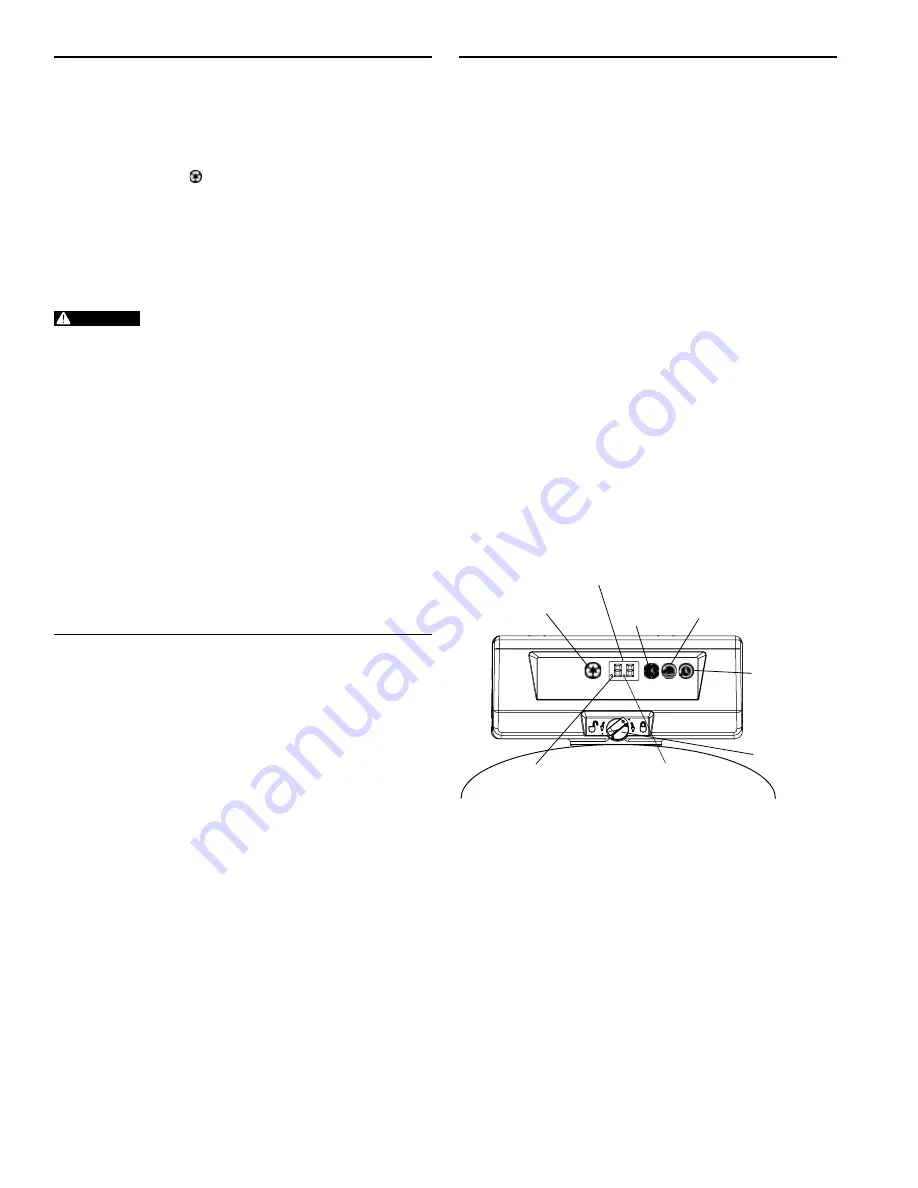

Large LED Display

A large two digit LED readout is highly visible in most

installation settings.

Simplified Three-Step Programming

Only three buttons are required to fully program the control.

Recycle Button

Initiates either a delayed or immediate cleaning cycle.

Time Button

Displays or programs the time of day.

Cleaning Cycle Interval Button

Displays or programs the amount of water to treat between

cleaning cycles.

Backwash Duration Button

Displays or programs the amount of time to elapse during the

backwash cycle step.

Flow Indicator

The decimal point/flow indicator blinks on and off when water

flow turns the meter.

Power Loss Memory Retention

The control features battery-free time of day retention during

loss of power. The time will remain in memory.

NOTE: All other programmed parameters are stored in the

flash memory and are retained during power outages.

Recycle

Button

Display

Time

Button

Backwash

Duration

Button

Cleaning Cycle

Interval/Days

Button

Remove

Cover

Delayed

Cleaning Cycle

Indicator

Flow

Indicator

Figure 8

6 •

Autotrol

®

363 Demand Automatic Filter Valve