PROGRAMMING THE 606F DEMAND

CONTROL

Time of Day:

Press to display the current time value in

hours. The time value is displayed as a number from 0 to 23,

with 0 representing midnight and 23 representing 11:00 PM.

While the value is being displayed, press the button to increase

the value. Press and hold the button to rapidly advance the

value. Release the button when the desired value is displayed.

The value will be stored in memory after five seconds.

Range:

0 - 23 hours

NOTE: The elapsed minutes will reset to zero when the hours

are changed.

Backwash Duration:

Press to display the current backwash

cycle step duration setting. The value in minutes will be

displayed for five seconds. While the value is being displayed,

press the button to increase the value. Press and hold the

button to rapidly advance the value. Press and hold the button

to rapidly advance the value. Release the button when the

desired value is displayed. The value will be stored in memory

after five seconds.

Range:

2 - 50 minutes

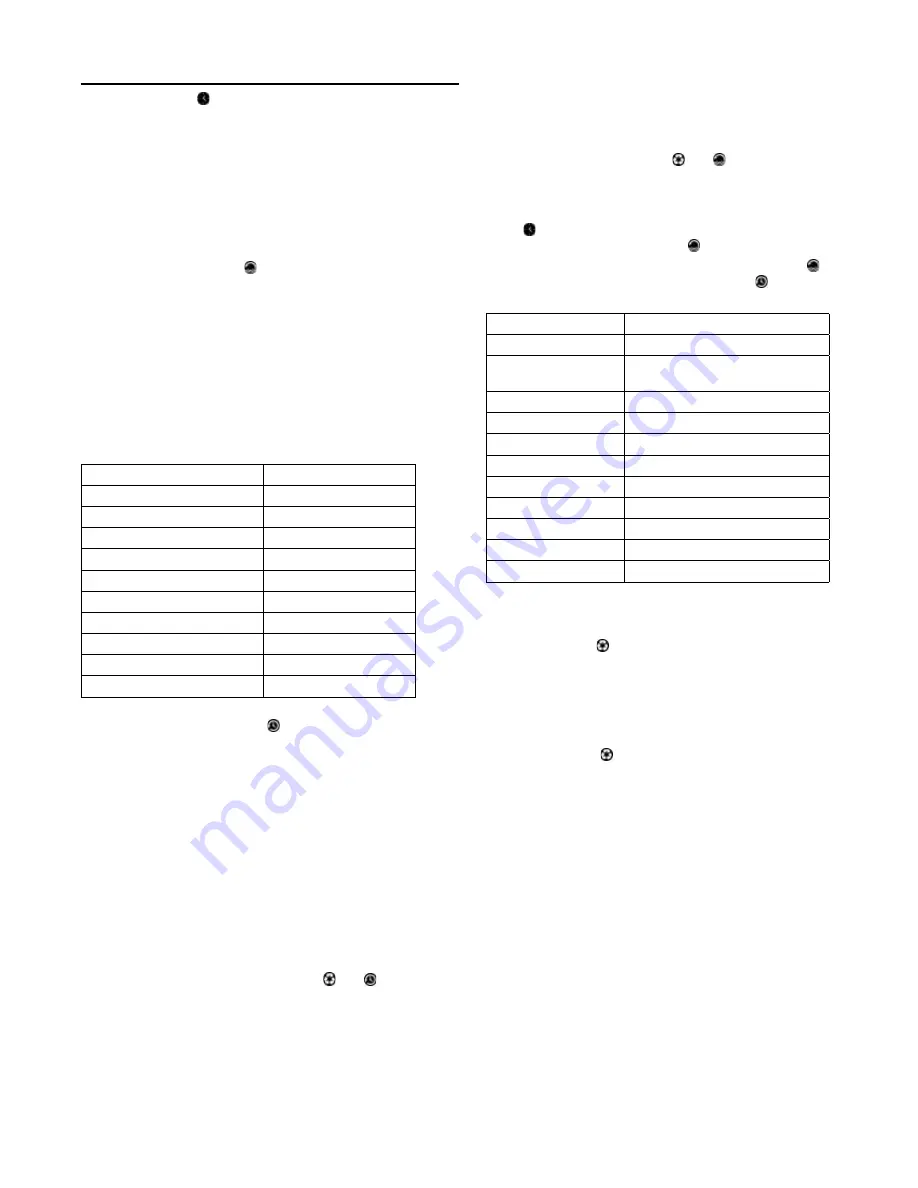

NOTE: The Rapid Rinse cycle step adjusts automatically

based on the Backwash Duration value. See table

below.

Backwash Time

Rinse Time

2 - 5 minutes

1 minute

6 - 9 minutes

2 minutes

10 - 13 minutes

3 minutes

14 - 17 minutes

4 minutes

18 - 21 minutes

5 minutes

22 - 25 minutes

6 minutes

26 - 29 minutes

7 minutes

30 - 35 minutes

8 minutes

36 - 40 minutes

9 minutes

41 - 50 minutes

10 minutes

Cleaning Cycle Interval:

Press to display the current

cleaning cycle interval setting. The value in cubic meters

(metric units) or hundreds of gallons (U.S. units) to treat

between cleaning cycles will be displayed for five seconds.

While the value is being displayed, press the button to increase

the value. Press and hold the button to rapidly advance the

value. Press and hold the button to rapidly advance the value.

Release the button when the desired value is displayed. The

value will be stored in memory after five seconds.

Range:

.4 - 9.5 cubic meters

100 - 4,000 gallons

Default:

1.0 cubic meters

10 x100 (1,000) gallons

Calendar Override:

To set a time duration between cleaning

cycles to ensure proper function of the filter in the event of a

flow sensor malfunction, press and hold and for three

seconds. The value in days between cleaning cycles will be

displayed for five seconds. While the value is being displayed,

press the button to increase the value. Press and hold the

button to rapidly advance the value. Release the button when

the desired value is displayed. The value will be stored in

memory after five seconds.

Range:

8 hours (0.3 days) - 30 days; 0 to disable

Default:

0 (disabled)

Accessing History Values

The control features a review level that displays the operation

history of the system. This is a great troubleshooting tool for

the control valve.

To access history values, press and simultaneously and

hold for three seconds to view the diagnostic codes.

NOTE: If a button is not pushed for 30 seconds the controller

will exit the history values table.

Press to advance through the table. When the desired

diagnostic code is reached, Press to display the value.

Some history values may have up to four digits. Press to

display the first two digits of the value. Press to display the

last two digits.

Code

Description

H1

Days since last cleaning cycle

H2

Current day of week

(displayed as 0 - 6)

H3

Water used today since 1:00 AM

H4

Water used since last cleaning cycle

A0

Average water usage for day 0

A1

Average water usage for day 1

A2

Average water usage for day 2

A3

Average water usage for day 3

A4

Average water usage for day 4

A5

Average water usage for day 5

A6

Average water usage for day 6

Manually Initiating A Cleaning Cycle

Delayed Cleaning Cycle

Press and release to program a delayed cleaning cycle. The

system will regenerate at the next cleaning cycle time

(1:00 AM). Repeat procedure to disable the scheduled cleaning

cycle. The display indicator dot blinks when a delayed cleaning

cycle is scheduled.

Immediate Cleaning Cycle

Press and hold the for three seconds to initiate an

immediate cleaning cycle. The control cycles to the backwash

cycle step. The control will proceed through a complete

cleaning cycle. A cascading symbol (- -) will be displayed until

the cycle is complete.

Autotrol

®

363 Demand Automatic Filter Valve • 7